All Facilities Operations Solutions

-

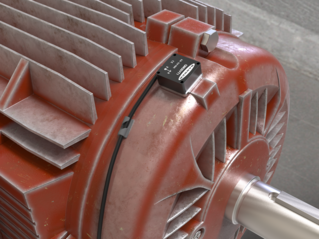

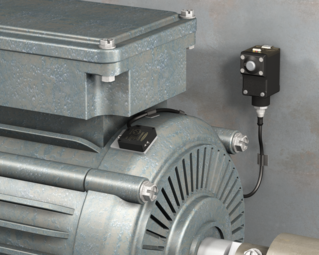

Wireless Motor Temperature Control and Monitoring

Wireless Motor Temperature Control and Monitoring

Instead of installing I/O transmission cabling, use a 10 to 30V dc powered Sure Cross Node and a Banner T-GAGE temperature sensor. When using host control systems, the Sure Cross Gateway transmits the temperature to the plant control room using a digital output related to temperature setpoints within the sensor. The motor is powered down or up based on these temperatures. When using a Gateway Pro as the wireless master device, the data ca be logged and alerts sent out to notify maintenance personnel when a motor is performing outside expected parameters.

-

Controlling Temperature and Humidity for a Cabinet Maker

Controlling Temperature and Humidity for a Cabinet Maker

A large cabinet maker needs to monitor and control the temperature and humidity throughout many rooms in a large production facility. Manual environmental readings of the entire plant were conducted periodically throughout the week. These manual readings only provided a snapshot of information and gathering the data took more than three hours. The customer did not have real-time, accurate information that could be used to control the plant environment. Manually collecting this information and controlling the fan system was timeconsuming and resulted in errors that damaged wood in storage, work in progress, and finished cabinets.

-

Equipment Monitoring from a Supervisor's Station

Equipment Monitoring from a Supervisor's Station

Provide at-a-glance machine status indication and send machine status information to a wide range of devices.

-

Environmental Monitoring inside a Machine Control Panel

Environmental Monitoring inside a Machine Control Panel

Identify small problems before they become major issues that impact machine performance and uptime.

-

Condition Monitoring: Predictive & Preventative Maintenance

Condition Monitoring: Predictive & Preventative Maintenance

Identify machine problems before they cause serious damage or unplanned downtime and alert staff of changes in condition via text message or email as well as provide at-a-glance local indication of machine status.

-

Monitoring Arrival and Departure of Trucks at a Loading Dock

Monitoring Arrival and Departure of Trucks at a Loading Dock

Sensor solution for outdoor truck detection for safety prevention purposes.

-

Delivery Truck Detection at an Outdoor Loading Dock

Delivery Truck Detection at an Outdoor Loading Dock

Automated solution to help alert workers of a delivery truck's arrival through the use of shifts in magnetic fields.

-

Exit Chute Jam Indication

Exit Chute Jam Indication

Banner’s Q30FF600 background suppression sensor confirms when a product enters the exit chute to ensure it came off the sortation system and that there isn’t a jam in the product chute. The Q30FF600 has long range sensing up to 600 mm, which is the standard width of many chutes.

-

Emergency Stop Buttons on a Conveyor

Emergency Stop Buttons on a Conveyor

Banner’s 30 mm mount E-Stop buttons work well in this type of application because they have an illuminated base that turns from yellow to flashing red when actuated. The red flashing illumination of the E-stop button visibly alerts operators which button was pressed so they can quickly and easily fix the problem to reduce down time and only reset the button that was activated.

-

Condition Monitoring on Conveyors

Condition Monitoring on Conveyors

Banner’s wireless solutions can have multiple gateways tied to respective nodes, allowing for elimination of all wires and providing flexible mounting options. The wireless structure of gateways and nodes are responsible for communicating the critical I/O throughout the facility. Even with multiple wireless products, the wireless communication system is efficient and has no cross talk interference and does not interfere with the IT department.

-

Emergency Indication on Conveyors

Emergency Indication on Conveyors

Banner’s RP-LS42 safety rope pulls line conveyors as a way to indicate emergencies and immediately shut down conveyors. If a rope pull is used during an emergency, it can be difficult to locate exactly where it was pulled. A K30 indicator light can be paired with the rope pulls in order to provide indication as to where the rope was pulled. This allows for quick and easy indication of where an emergency occurred, helping to return to normal operations as fast as possible.

.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)