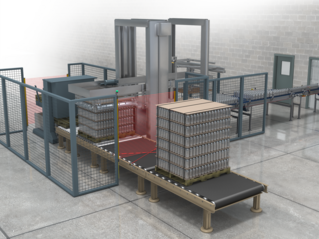

Beverage: Primary Packaging

Primary packaging for beverage producers begins with the introduction of empty containers onto the line. Before moving onto secondary packaging, containers will be rinsed, filled and finally capped at very high-speeds. All along the beverage filling line, each phase in this process poses unique challenges to equipment and operators.

Banner is a leader in the design and development of products and solutions that bottlers, all around the world, rely on to perform in this challenging area. From stainless steel, IP67, IP68 and IP69k rated sensors that withstand wet, washdown conditions to heavy duty safety light screens that guard access points to depalletizers and blow molders, Banner offers a broad range of products that solve difficult primary packaging applications in beverage production.

Our application experts have years of experience and industry knowledge and can draw on our impressive catalog to help your company find and implement products and solutions that ensure a smooth and continuous flow of containers through the system.

Primary Packaging Beverage Applications

View Applications by Machine Type

Featured Applications

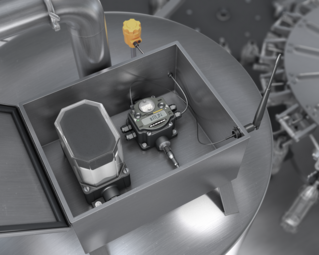

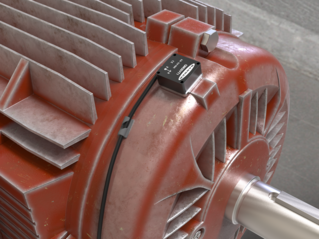

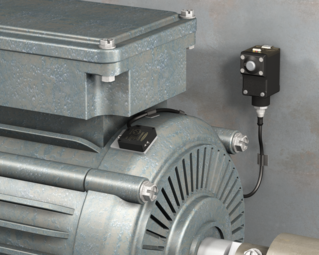

Slip Ring Replacement with Wireless Solutions

Slip rings are subject to constant movement which in turn leads to continuous maintenance in order to avoid degradation of the rotating electrical connection caused by normal wear and debris. Slip ring failure bring production to a halt, resulting in unexpected and costly downtime. The DX80 wireless radios provide a non-contact solution for transmitting the sensor signals from inside the filler bowl to the control panel. The wireless node located on the rotary filler can be battery powered thus providing power to the sensors for a wire-free installation. The DX80 wireless solution eliminates the need for slip rings, helping to decrease downtime and maintenance.

Identifying Presence and Height of a Bottle Cap

The iVu Plus Gen 2 vision system, paired with a Q4X and LEDRB backlight, offer a solution that will provide dependable results.

Clear Container Detection in a Clean-in-Place Rotary Filler

Track bottles as they move through the rotary filter.

.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)