Cost-Effective LED Lights Replace Fluorescent Fixtures in Machine Enclosures [Success Story]

A single 285 mm WLB32 industrial LED light bar illuminates an ultrasonic weld machine enclosure, replacing a two-foot, dual-bulb fluorescent light fixture

Customer Requirements: Brilliant, cost-effective illumination of ultrasonic weld machine enclosures

Solution: WLB32 industrial LED light bar

Why Banner? Value – WLB32 LED lights provided superior illumination, efficiency and longevity and were cost comparable to fluorescent fixtures

Compact Design – A fraction of the size of the fluorescent fixture, the WLB32 fit in an optimal position to illuminate the work area

Customer Benefits

Flexibility – The company is able to standardize on the optimum LED length for each specific enclosure type and select the AC or DC power option best suited to the application

Background

An equipment manufacturer designs and builds ultrasonic weld machines used for many manufacturing applications. A machine made for an automotive components manufacturer is housed in a large enclosure. Illumination of the enclosure allows operators to monitor the welding process and facilitates machine maintenance.

Challenges

The enclosure was illuminated by a two-foot long, dual-bulb fluorescent light fixture mounted at the top of the enclosure wall. The light it created was inconsistent and uneven. The bulbs required regular replacement and special handling for disposal. Periodic ballast replacements further complicated maintenance. The company had considered switching to an LED solution, but cost had been prohibitive.

Solution

A WLB32 industrial LED light bar is more efficient at directing light with a more uniform distribution of light than fluorescent alternatives. In a direct comparison, a two-foot long WLB32 on its dim setting outshined a two-foot dual bulb T8 fluorescent light. The company chose the WLB32 light bar for this deployment and Banner LED lighting solutions are now the standard for the end user as well.

WLB32 industrial LED light bars are available in AC and DC powered models. Integrating DC powered models into the machines allowed the company to eliminate the expense of installing separate AC circuits and reduced machine build times. By standardizing on the form factor of the WLB32, the company has the flexibility to choose the power variant that best meets the customer’s requirements.

These cost-effective LED light bars will provide continuous low-power illumination across their entire lifespan. The superior performance and longevity of Banner’s solution allowed the company to eliminate yearly bulb replacements for over 100 work stations on this deployment alone, providing the customer with more machine uptime and saving them the time and expense of replacing over 200 bulbs annually.

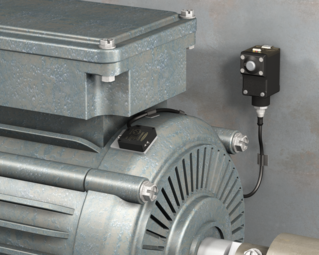

![Vibration Monitoring a Main Air Handler [Success Story]](/content/dam/banner-engineering/3d-renders/application-notes/predictive-maint/qm30vt-motor-vibration-detection.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![대형 크레인의 모터 및 기어박스의 예측 유지 보수 [성공 사례]](/content/dam/banner-engineering/photography/general---stock-photography/stock_photo_new/bigstock-In-A-Port-49071524.jpg/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![컨베이어의 회전 부품 예측 유지 보수 [성공 사례]](/content/dam/banner-engineering/photography/general---stock-photography/stock_photo_new/AdobeStock_111970609.jpeg/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![열정화 온도 측정 [성공 사례]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2013/SURE-CROSS-Flex-Power-w-RTD---Temp-Measure-in-Flour-Mill.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![다양한 등록 기호 감지[성공 사례]](/content/dam/banner-engineering/photography/general---stock-photography/valueprop/edited/wcc-migration/2015/R58_roll_closeup.jpg/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Simplifying Safety Feature Management [Success Story]](/content/dam/banner-engineering/photography/general---stock-photography/valueprop/edited/wcc-migration/2015/Algus_MKuhlow.jpg/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![LED Light Bars Outshine Fluorescents, Reduce Machine Build Times & Expenses [Success Story]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/WLB32%20Muti-Station%20Test%20Workstation%20Illumination%20(High_Res_PSD).psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Long-Lasting LEDs Install Quickly to Illuminate Web Inspection Stations [Success Story]](/content/dam/banner-engineering/photography/success-story-photography/WLB32-LED-Lights-Web-Inspection.jpg/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![무인 차량의 상태 표시 [성공 사례]](/content/dam/banner-engineering/photography/general---stock-photography/stock_photo_new/AdobeStock_189577689.jpeg/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![제과점 재료의 정확한 측정 [성공 사례]](/content/dam/banner-engineering/photography/general---stock-photography/valueprop/edited/wcc-migration/2015/dropbox3.jpg/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![소형 커넥터 검사 [성공 사례]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2014/LE550-Vehicle-Seat-Weight-Sensor-Connector.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![산업용 와인더의 무결점 표준 [성공 사례]](/content/dam/banner-engineering/photography/general---stock-photography/valueprop/edited/wcc-migration/2015/Fotolia_51604759_M.jpg/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![액체 의약품 검사에 사용되는 LED 조명[성공 사례]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2011/WLA-IV-Bag-Manual-Inspection---Particulates.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Vent Tube Presence on Filler [Success Story]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2013/iVu-C-Mount-Remote-washer-Tube-Inspection.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![응급 상황 시 출동 시간 측정[성공 사례]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2014/R-GAGE-Vehicle-Detection---Firehouse.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)