Predictive Maintenance and Condition Monitoring

Maintenance Based on Data from the Machine Itself

Predictive maintenance is becoming essential to the smart factory. Predictive maintenance enables users to more accurately anticipate when machine maintenance will be needed based on real-time data from the machines themselves.

The ability to accurately track machine performance and anticipate failures before they occur is helping manufacturers improve productivity and reduce wasted time and costs.

What It Is and Why It Matters

Predictive maintenance is the process of tracking the performance of crucial machine components, such as motors, to minimize downtime needed for repairs. Predictive maintenance enables users to more accurately anticipate when machine maintenance will be needed based on real-time data from the machines themselves.

Traditionally, plant managers relied on preventative maintenance schedules provided by a machine’s manufacturer, including regularly replacing machine components on a suggested timeline. However, these timelines are only estimates of when the machine will require service, and the actual use of the machine can greatly affect the reliability of these estimates.

For example, if bearings wear prematurely or a motor overheats, a machine may require service sooner than anticipated. Furthermore, if a problem goes undetected for too long, the issue could escalate to further damage the machine and lead to costly unplanned downtime. Predictive maintenance helps avoid these problems, saving time and costs.

Vibration & Temperature Indicate Machine Health

Condition monitoring plays a key role in predictive maintenance by allowing users to identify critical changes in machine performance. One important condition to monitor is vibration. Machine vibration is often caused by imbalanced, misaligned, loose, or worn parts.

As vibration increases, so can damage to the machine. By monitoring motors, pumps, compressors, fans, blowers, and gearboxes for increases in vibration, problems can be detected before they become severe and result in unplanned downtime.

Vibration sensors typically measure RMS velocity, which provides the most uniform measurement of vibration over a wide range of machine frequencies and is indicative of overall machine health. Another key data point is temperature change (i.e. overheating).

Automatically Set Baseline & Alert Thresholds

Machine learning takes condition monitoring data and automatically defines a machine's baseline conditions and sets thresholds for acute and chronic conditions so that you know in advance--and with confidence--when your machine will require maintenance.

After mounting the vibration sensor onto your machine, most sensors require you to collect enough data to establish a baseline for the machine. Machine learning removes the chances of human error by automating the data analysis.

A condition monitoring solution with machine learning will recognize the machine’s unique baseline of vibration and temperature levels and automatically set warning and alert thresholds at the appropriate points. This makes the condition monitoring system more reliable and less dependent on error-prone manual calculations.

Real Time Alerts, Long Term Optimization

When a vibration or temperature threhold has been exceeded, a smart condition monitoring system provides both local indication, such as sending a signal to a tower light in a central location, and remote alerts like emails or text messages. This ensures that warnings are addressed quickly.

In addition, a condition monitoring solution that allows you to log the collected data over time enables even more optimization. With a wireless system, vibration and temperature data can be sent to a wireless controller or programmable logic controller (PLC) for in-depth, long-term analysis.

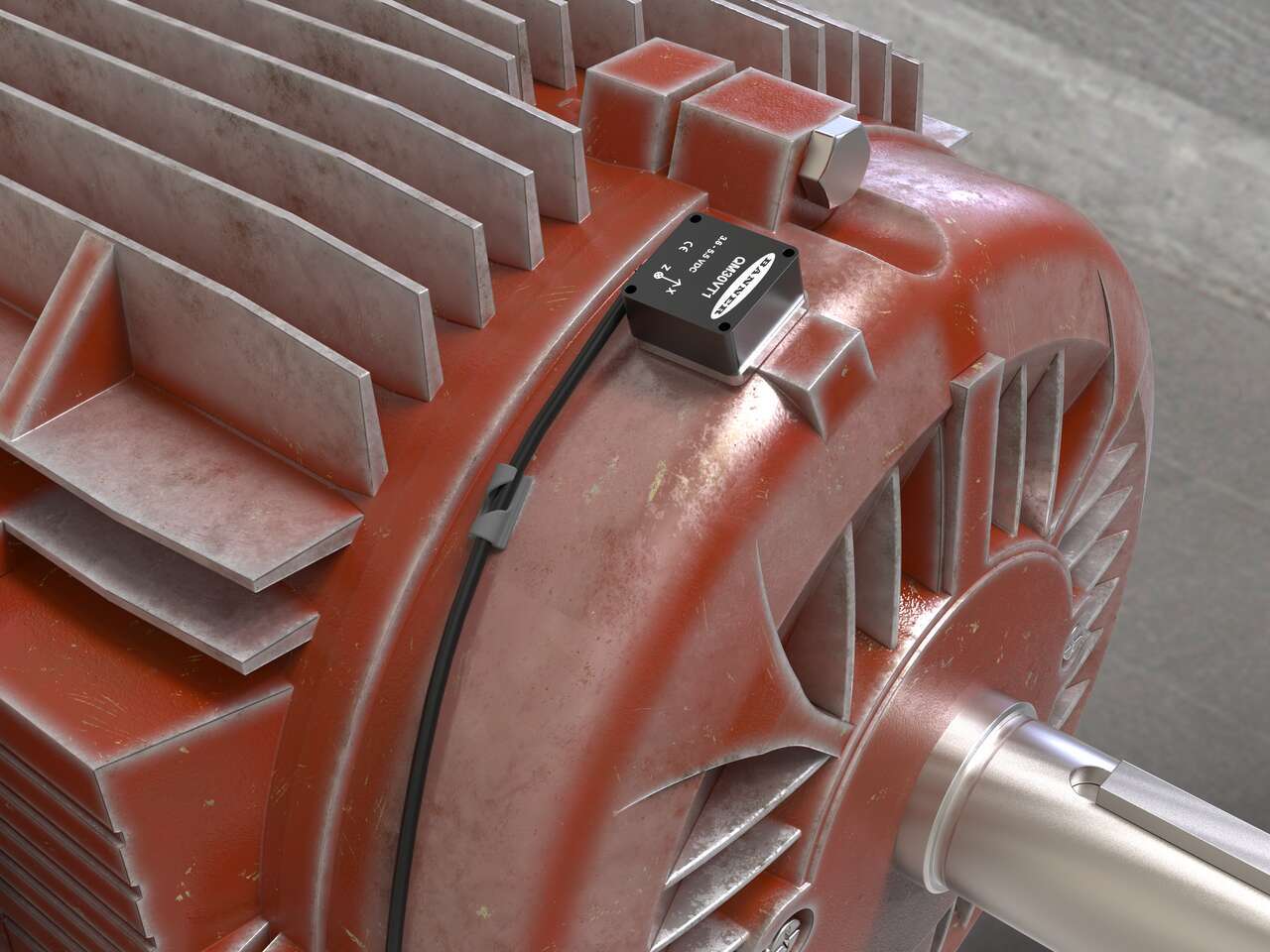

Vibration and Temperature Sensor

QM30VT 시리즈 센서는 공명 간섭을 줄이고 표면 접촉을 늘려주는 로우 프로파일 디자인과 견고한 금속 구조를 채택하여 RMS 속도 및 온도 측정에서 탁월한 수준의 정밀도를 제공합니다. 또한, 장비 진동 및 온도의 매우 미세한 증가도 감지할 수 있으므로 잠재적인 문제를 조기에 확인할 수 있습니다.

- 멀티홉 Modbus 통신 장치 또는 1선식 시리얼 노드를 사용하여 DXM 시리즈 무선 컨트롤러 또는 게이트웨이에 성능 데이터를 전송할 수 있습니다.

- 모터, 팬, 펌프 및 기타 회전 동작이나 진동이 있는 모든 장비의 잠재적인 문제를 감지합니다.

- 작은 공간에도 손쉽게 배치할 수 있는 초소형 디자인

- 316L 스테인리스 스틸 하우징 또는 고강도 알루미늄 하우징 모델로 공급됩니다.

- 커넥티드 데이터 솔루션 소프트웨어, 진동 및 온도용 무선 솔루션 키트와 완벽 호환

For Vibration Monitoring

Wireless Controller for IIoT Applications

DXM 시리즈 산업용 무선 컨트롤러는 이더넷 연결과 IIoT(산업용 사물인터넷) 응용 분야의 발전을 촉진하도록 설계되어 있습니다.

- 로컬 무선 네트워크의 경우 900MHz 및 2.4GHz에서 사용 가능한 ISM 무선 장치

- Modbus RTU를 Modbus TCP/IP 또는 이더넷 I/P로 변환

- 작업 규칙 및 텍스트 언어 방식으로 로직 컨트롤러 프로그래밍 가능

- 데이터 로깅을 위한 Micro SD 카드

- 이메일 및 문자 알림

- 셀룰러 연결을 위한 셀 모뎀