Automated Quality Control

Identify Issues Early and Save Costs

Defects and errors in parts and components can negatively impact downstream processes, production efficiency, and product quality.

Consistent, reliable inspection of parts and components can help manufacturers identify potential issues early on in the manufacturing process, minimizing costly lost product and production time.

Banner’s expertise in a range of sensing technologies allows us to offer optimal quality control solutions for detecting defects, measuring components, monitoring tolerances, and verifying attributes.

Rugged, Reliable Sensors are Required

Automated quality control applications often involve inspecting challenging targets, such a clear and reflective targets, extremely dark targets against a dark background, multicolored targets with many color transitions, and targets moving at high speeds.

Depending on the application, the smallest errors can become critical failures further down the line, making precise inspection a must. In some applications, quality control inspections occur in extremely harsh environments, where sensing technology can be exposed to dust and dirt, high pressure washdown, machine vibration, and more.

Banner Engineering offers a range of rugged, reliable photoelectric, laser measurement, and vision sensors that improve your automated quality control processes--even in the most challenging applications. Keep reading to learn more, or contact us to discuss your specific application.

Reliably Inspect Every Target

Fast, reliable quality inspections are essential to ensuring consistent throughput without sacrificing quality.

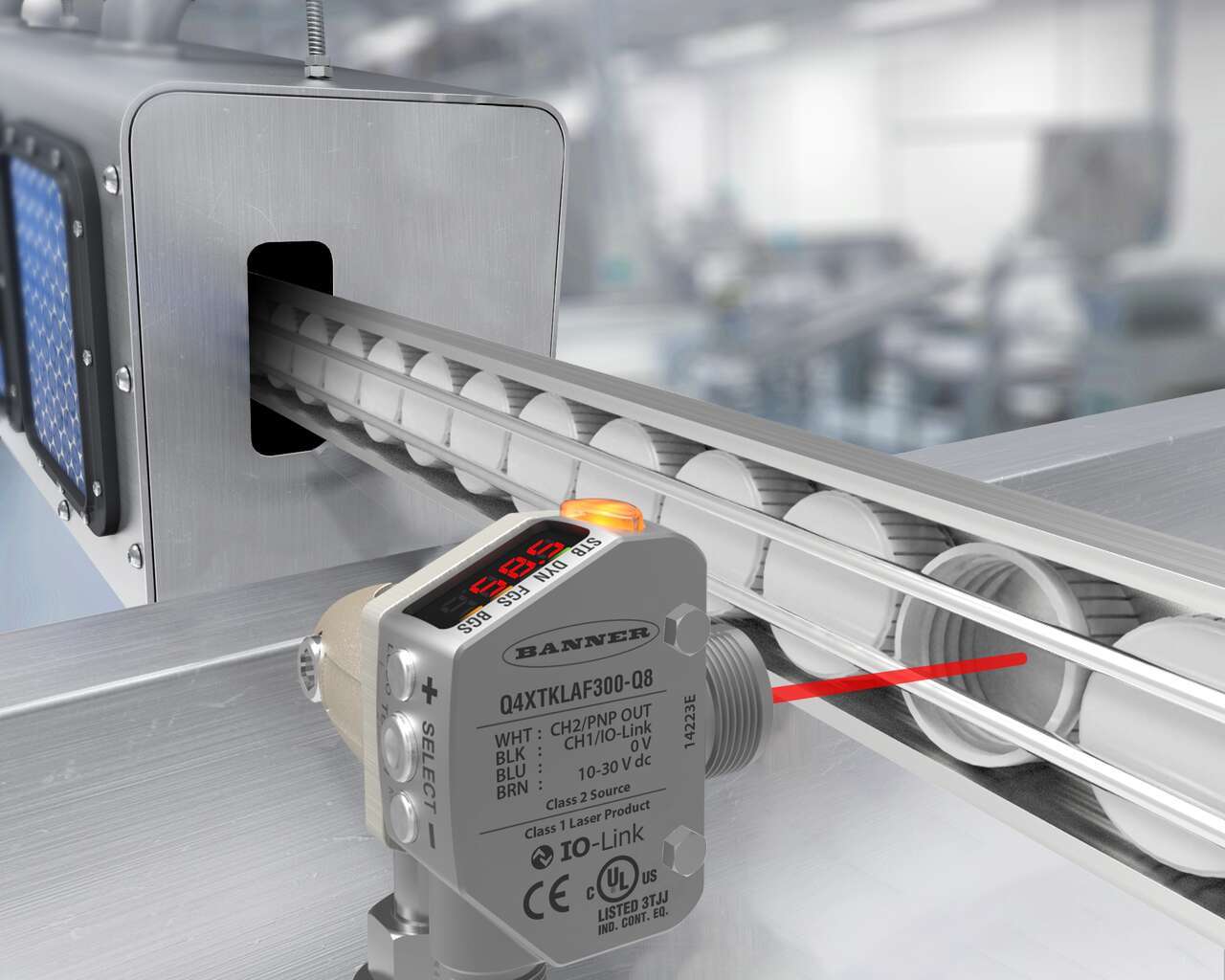

Thanks to advancements in laser measurement technology, sensors can now measure traditionally challenging targets (including clear, reflective, and low contrast targets). For example, the Q4X laser measurement sensor reliably inspects extremely dark targets on aginast an equally dark background.

in addition, thanks to dual mode which measures both distance and light intensity, smart laser measurement sensors from Banner can reliably inspect both distance-based and contrast-based conditions with a single device, which saves inventory costs.

Furthermore, with IO-Link communication, users can track sensor performance, identify trends in inspection results, and even predict when maintenance is needed so that simple problems like a dirty lens can be fixed prior to sensor failure.

Maintain Tight Tolerances

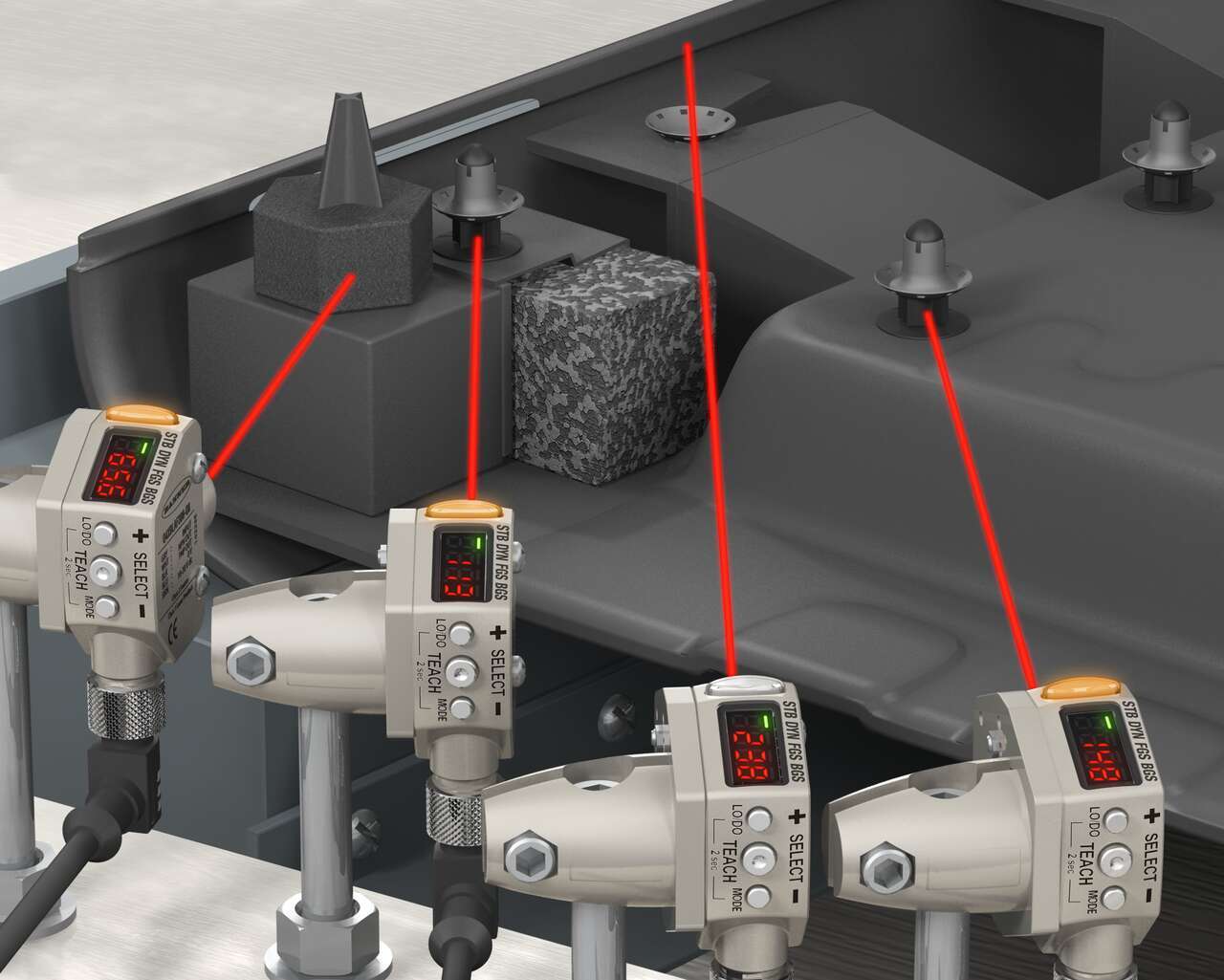

Quality control applications that require precise measurement can be some of the most challenging applications to solve. Very tight tolerance requirements demand a reliable solution that can measure parts in micrometers to detect the smallest variations in part size, thickness, orientation, placement, and more. Ensuring parts meet strict quality standards can help reduce problems downstream and reduce the risk of product recall due to imperfect parts.

Laser measurement sensors are a common solution for precise part inspections. However, real world conditions—including variations in target color and reflectivity, fluctuations in ambient temperature, and vibration from improper mounting—can make precise measurement challenging, even for laser sensors that perform well in perfect laboratory conditions.

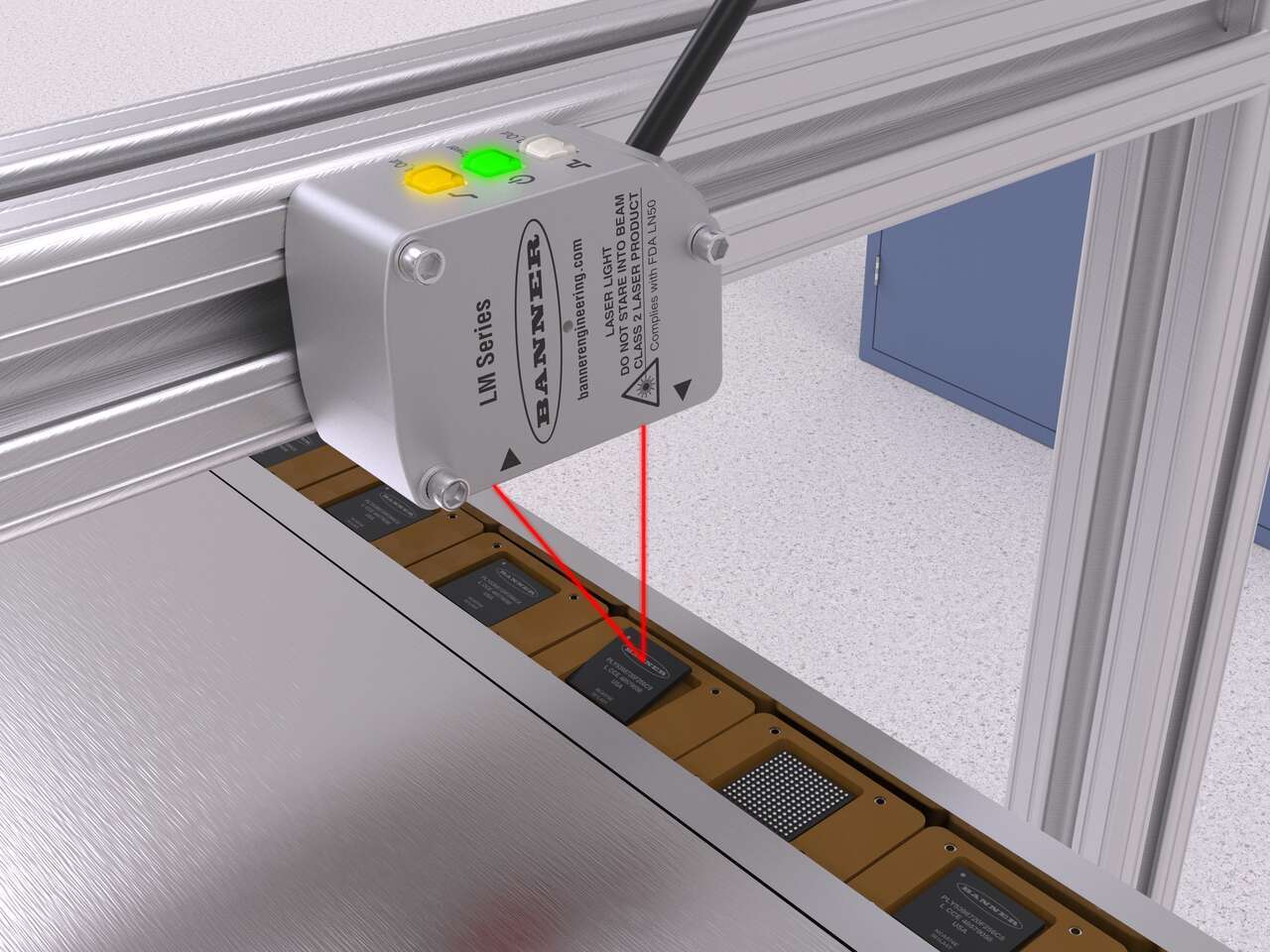

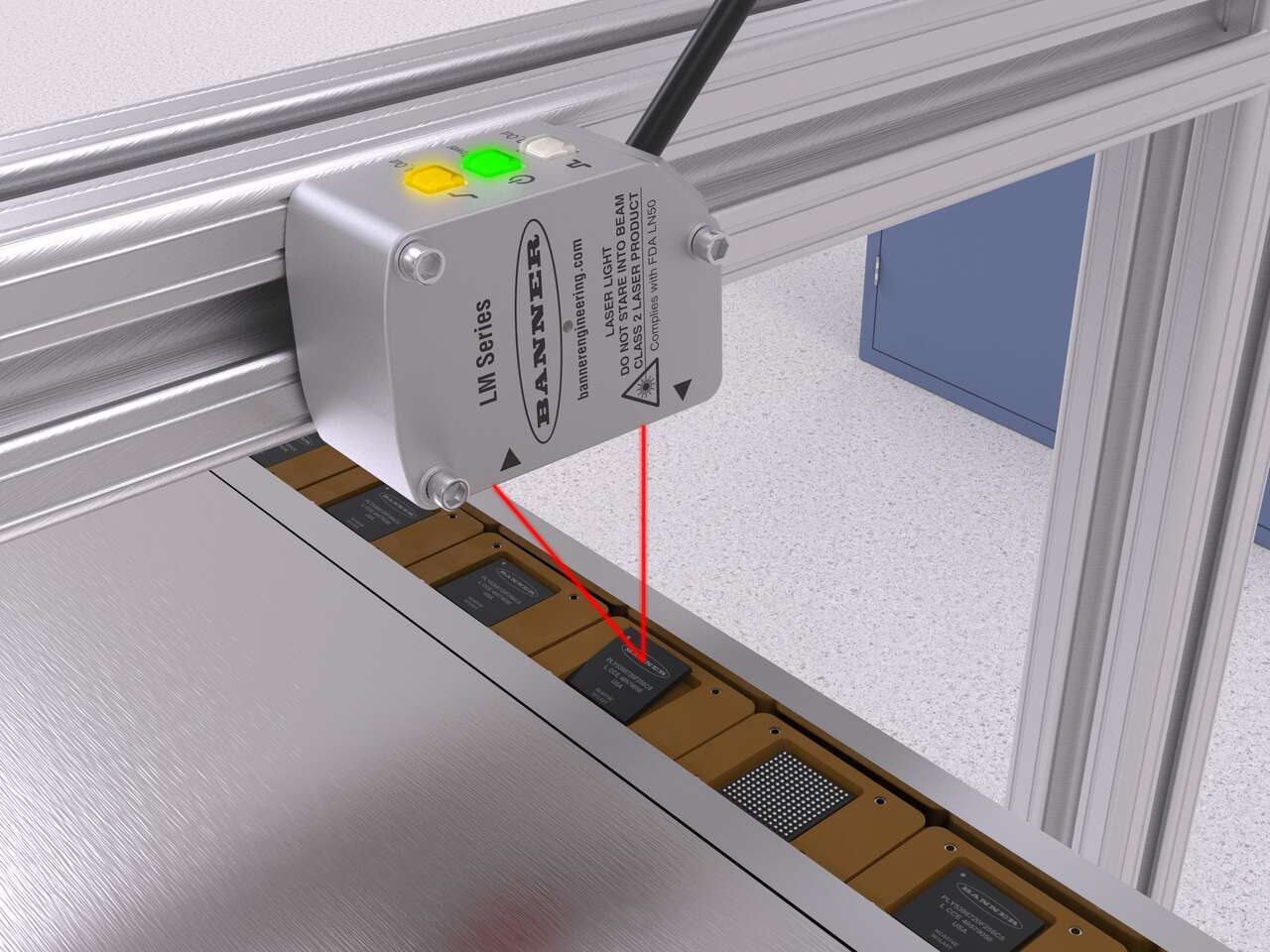

The LM Series precision measurement sensor from Banner Engineering offers best-in-class performance with superior stability, reliability, and precision for real world targets.

Prevent Errors at the Source

Error proofing refers to preventing a process from resulting in defects by stopping mistakes at the source, rather than down the line. Preventing mistakes at the source can significantly improve productivity by keeping mistakes from becoming bigger problems downstream.

In automated processes, error proofing solutions like sensors and vision systems can be used to ensure poblems are corrected before a process can proceed.

Meanwhile, in manual processes, such as bin picking, visual warnings clearly indicate to operators when their actions are correct or incorrect using colored and/or animated lights. Light-guided assembly is an excellent example of using visual indication for error-proofing.

Precision Measurement Sensor

LMシリーズ 高精度測定センサは、直感的なユーザー体験を作り出すコンパクトな装置でクラス最高のパフォーマンスと実世界における安定性を提供しています。

- 0.002~0.004 mmの分解能による高精度測定

- 0.5 msの高速応答、0.25 msのサンプル速度

- 小さなスペースにもフィットするコンパクトなハウジング設計

- クラス最高の熱・機械安定性

- 化学的適合性を実現するIP67およびグレード316ステンレス鋼製

- リモート監視・セットアップ用のリモートセンサディスプレイ (RSD) (オプション)

- IO-Link®、ディスクリート、アナログ出力を1つのモデルに備えたインダストリー4.0/IIoT対応

iVu Series

Vision Sensor

iVuまたはiVuカラーイメージセンサは、部品の種類、サイズ、向き、形状、位置、および色または色のバリエーションの監視に使用できます。

- カメラ、コントローラ、レンズ、そして照明が一体になったオールインワンのソリューション

- Vision Manager PCソフトウェア、オンボードのタッチスクリーンディスプレイ、またはリモートタッチスクリーンを使ってわずか数分で構成

- さまざまなグレースケールまたはカラーツールで複数のポイントを検査

- コンパクトで頑丈なIP67ハウジング。統合リングライト付き (赤、青、緑、白、赤外線、UV) または無しで提供

- 適用の柔軟性を最大限に高める、Cマウント付き可換レンズ

- イーサネット/IP™、Modbus/TCP、PROFINET®、PCCC、およびシリアルRS-232

![液体薬剤の検査に使用するLEDライト [成功事例]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2011/WLA-IV-Bag-Manual-Inspection---Particulates.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)