Precision Measurement

Solve Applications with the Tightest Tolerances

Precise measurement applications can be some of the most challenging to solve. Extremely tight tolerance requirements demand a reliable solution that can measure parts in micrometers to detect the smallest variations in part size, thickness, orientation, placement, and more.

Ensuring parts meet strict quality standards can help reduce problems downstream and reduce the risk of product recall due to imperfect parts.

Real world conditions—including variations in target color and reflectivity, fluctuations in ambient temperature, and vibration from improper mounting—can make precise measurement challenging, even for laser sensors that perform reliably in perfect laboratory conditions.

Even seemingly insignificant details, like pushing buttons on the sensor, can negatively impact the device's precision.

Therefore, it is important to understand the factors that can impact measurement precision in order to identify a solution that can overcome these challenges.

Keep reading to learn several key considerations to help you find the right sensor for your most precise measurement applications, or contact us to discuss your application with an expert.

WHY resolution isn't everything

For precise applications, measurement in micrometers is essential. However, while resolution is very important for precise applications, resolution specifications only represent a sensor’s performance in “best case” conditions.

Because of this, resolution specifications often do not provide a complete picture of a sensor’s capabilities in the real world and sometimes overstate sensor performance.

Therefore, it is important to consider the resolution specification in combination with other indicators of the sensor’scapabilities.

In discrete sensing applications, it is also important to consider the sensor’s repeatability (how reliably the sensor can repeat the same measurement in the same conditions) and the minimum object separation (the minimum distance a target must be from the background to be reliably detected).

For analog applications, it is important to consider both the sensor’s resolution and its linearity (how closely the analog output approximates a straight line across the measuring range) to ensure a reliable output across the full range of the sensor.

When combined with resolution, these additional specifications provide a more complete picture of sensor performance in the real world.

Real World Targets and Temperature Fluctuation

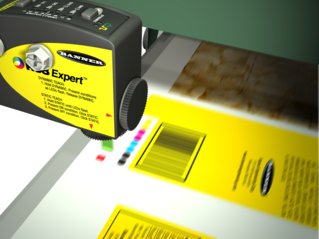

Real world targets are often difficult to measure consistently. Depending on the industry and application, objects may be very dark (low reflectivity), glossy (high reflectivity), or contain multiple color transitions—all of which can significantly impact measurement reliability.

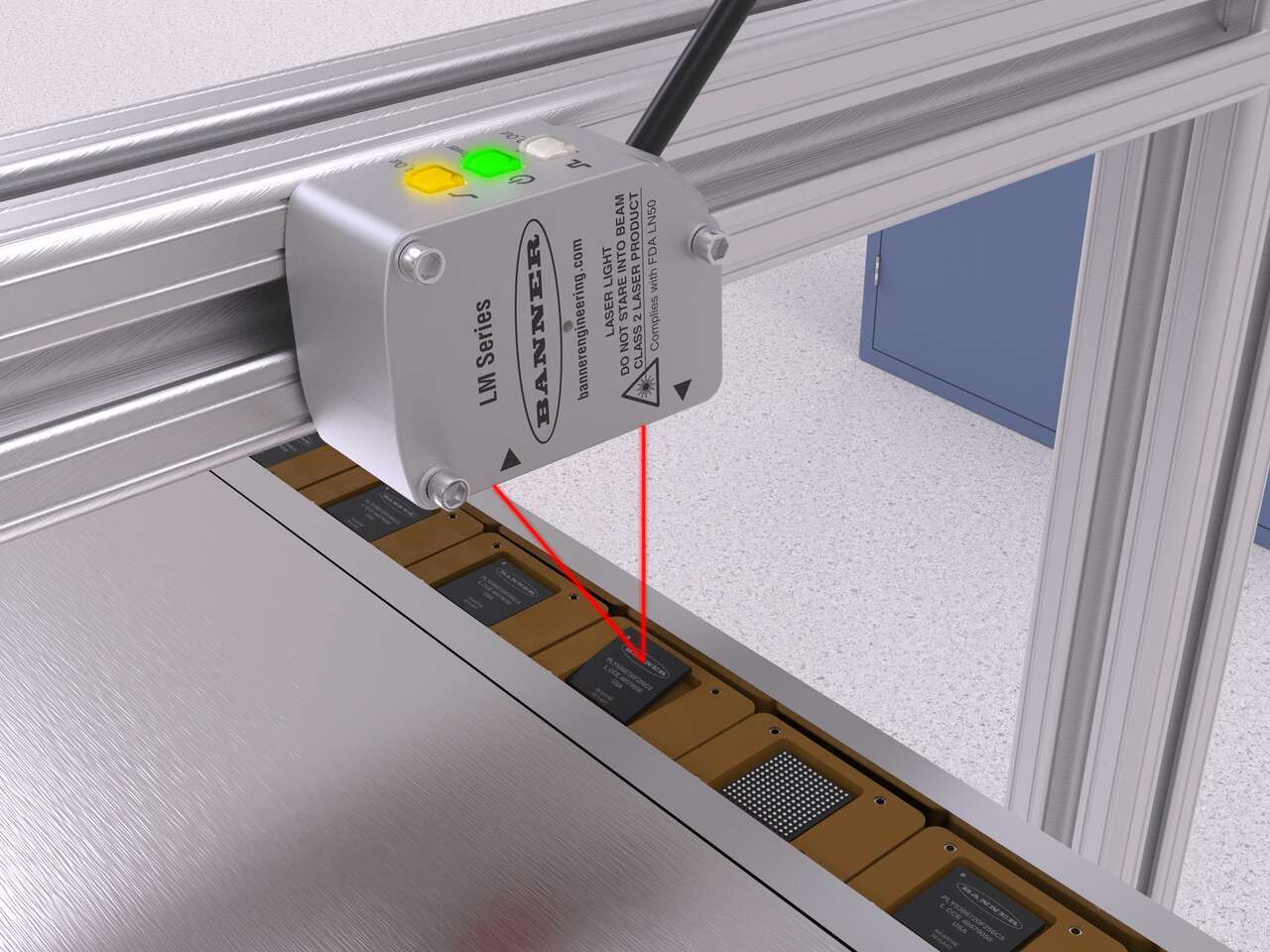

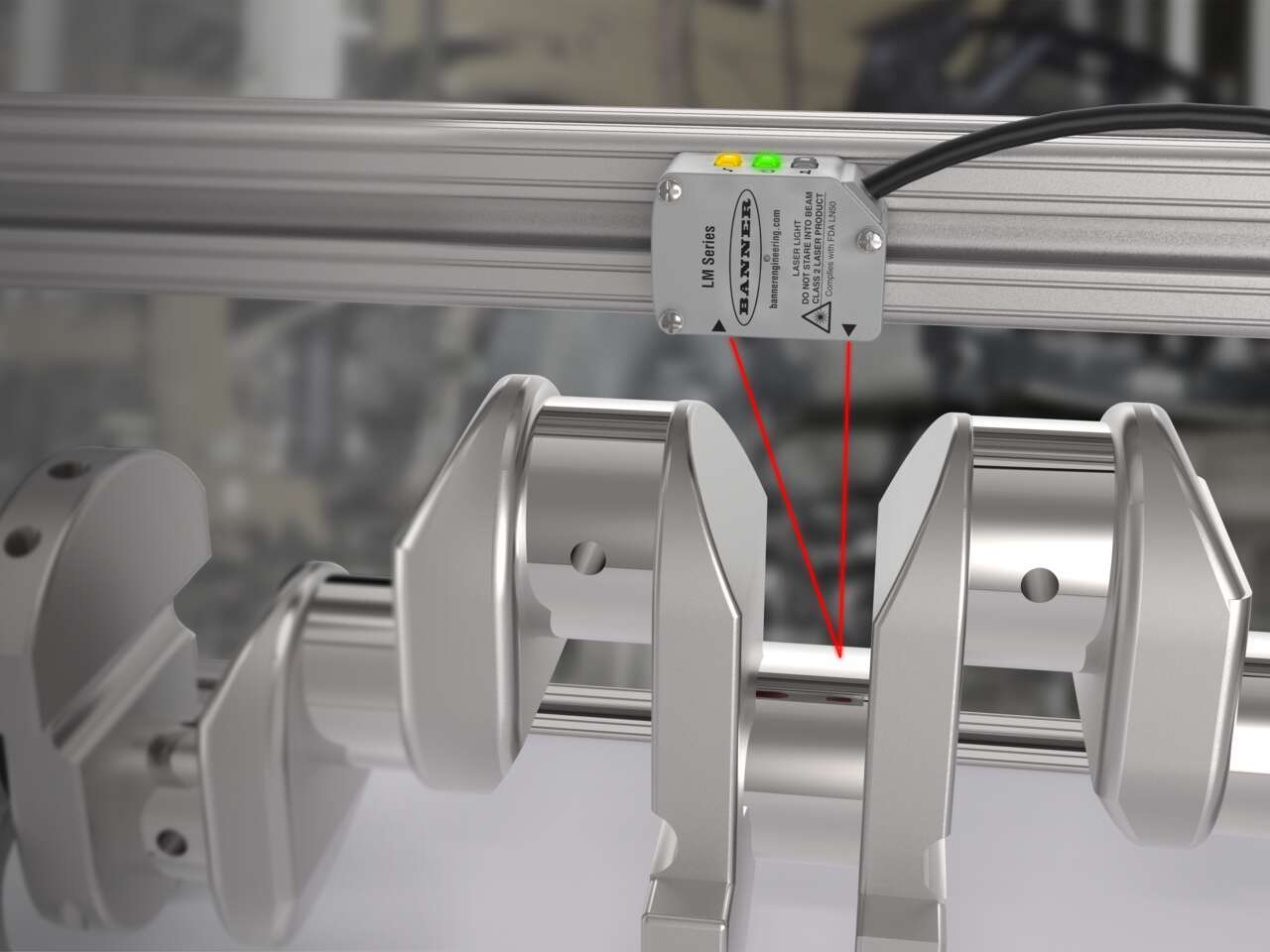

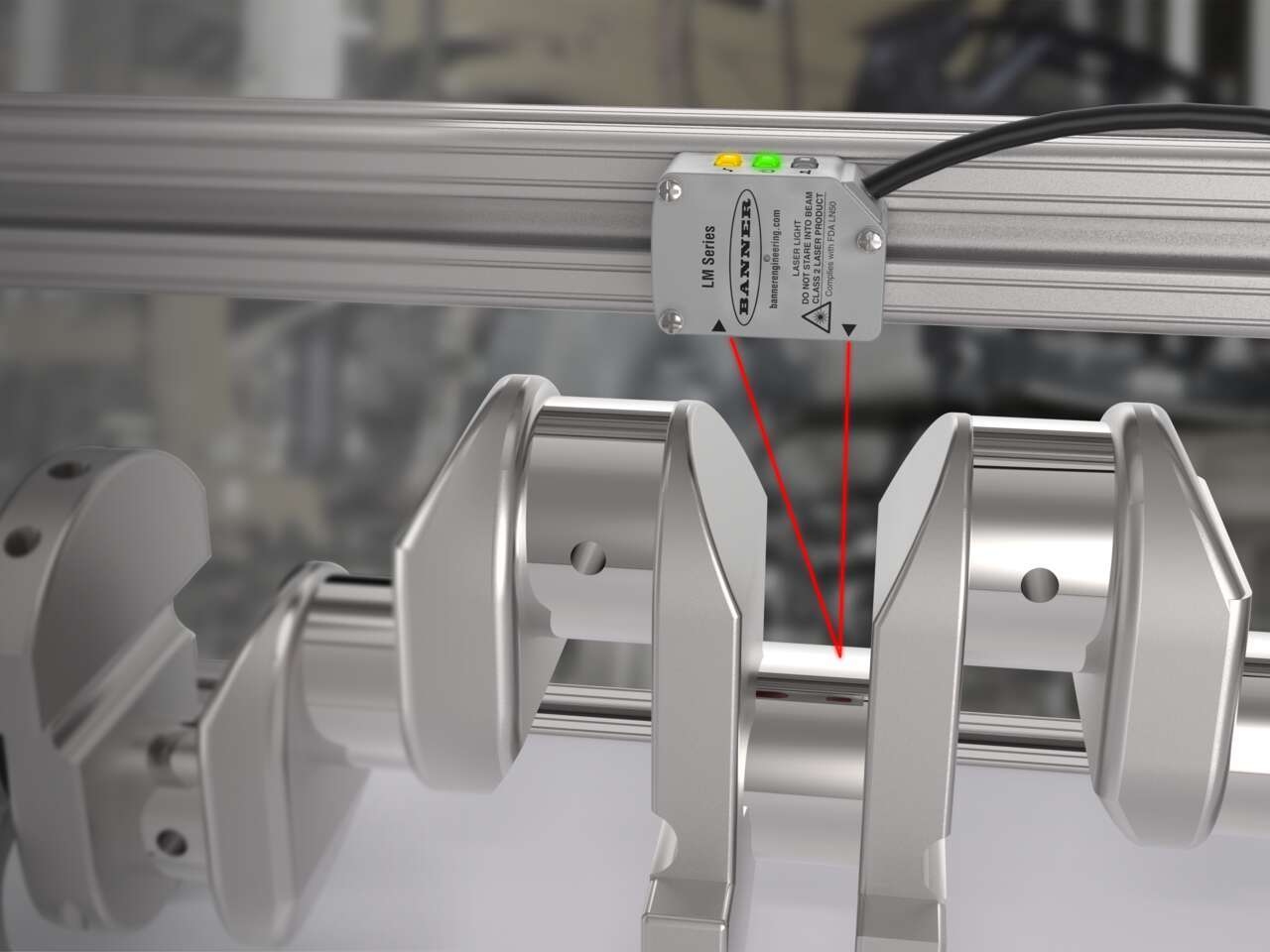

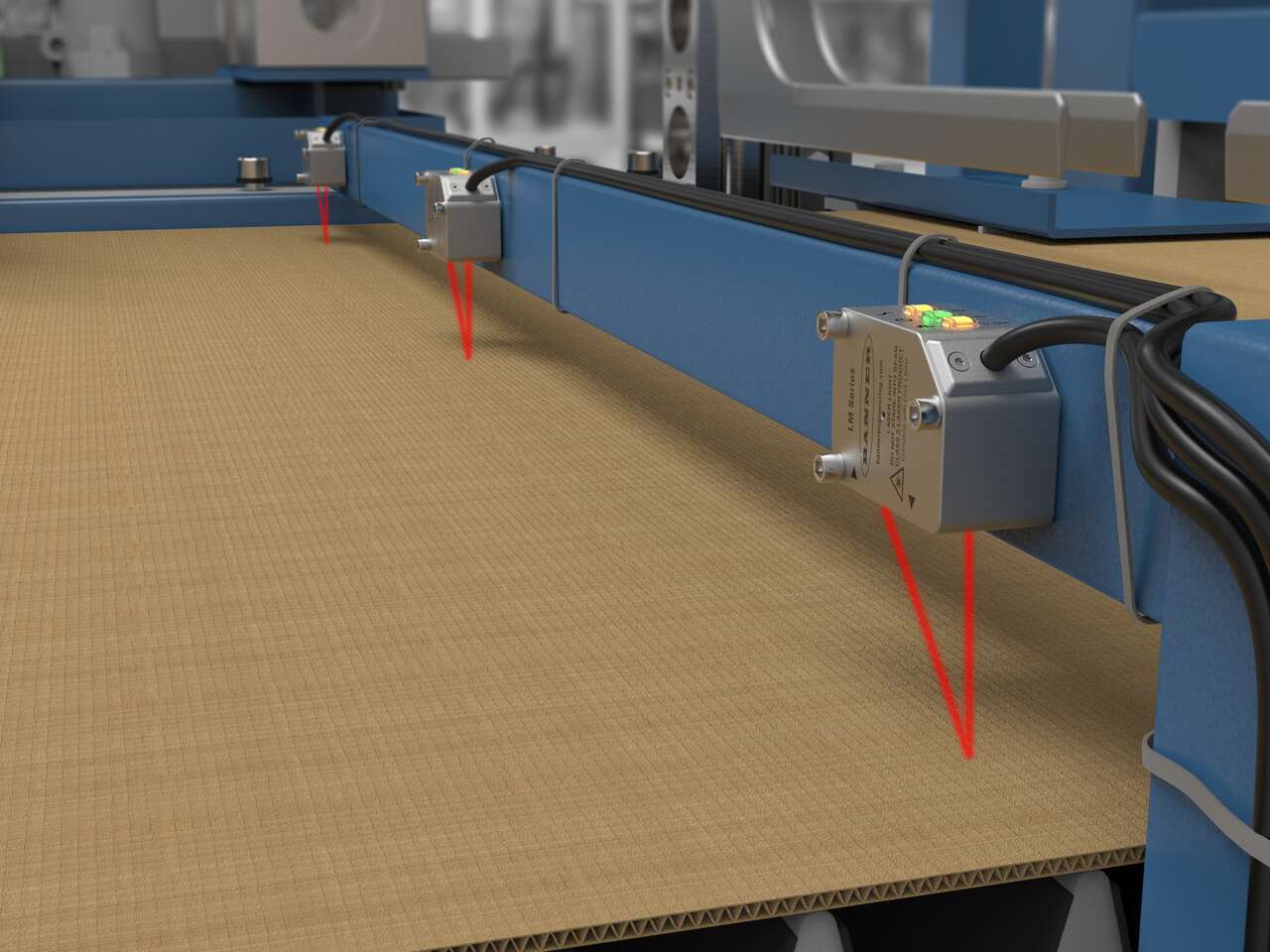

To mitigate this issue, some laser measurement sensors like the LM Series feature automatic gain adjustment, which means the sensor dynamically reduces or increases its power based on the reflectivity of the target. This ensures targets of varying colors and reflectivity are all measured reliably.

Precision measurement can also be greatly affected by changes in ambient temperature. For some sensors, temperature fluctuations of even a few degrees up or down throughout the day can cause the sensor’s measurement error to double, eliminating any benefit of a precision sensor. Therefore, it is essential to choose a sensor with high thermal stability for reliable measurement regardless of the surrounding temperatures.

Remote Configuration & Monitoring for Precision

Finally, choosing the right configuration and mounting options can help ensure the precision of a sensor.

Mounting stability is crucial for a precision measurement sensor. Even with the best specifications, if a precision sensor isn’t mounted securely, measurements will not be reliable. To reduce the risk of measurement error, ensure that the sensor can be securely fastened to the mounting fixture and kept away from excessive vibration.

Remote configuration and monitoring options, via IO-Link or Banner's RSD1 remote sensor display, enable the sensor to be configured without pushing buttons directly on the device. This reduces the risk of button movement interfering with the sensor's precision.

Remote configuration and monitoring options also enable users to gather health and performance data from the sensor, which allows manufacturers to predict maintenance requirements and make data-driven decisions.

Precision Measurement Sensor

LMシリーズ 高精度測定センサは、直感的なユーザー体験を作り出すコンパクトな装置でクラス最高のパフォーマンスと実世界における安定性を提供しています。

- 0.002~0.004 mmの分解能による高精度測定

- 0.5 msの高速応答、0.25 msのサンプル速度

- 小さなスペースにもフィットするコンパクトなハウジング設計

- クラス最高の熱・機械安定性

- 化学的適合性を実現するIP67およびグレード316ステンレス鋼製

- リモート監視・セットアップ用のリモートセンサディスプレイ (RSD) (オプション)

- IO-Link®、ディスクリート、アナログ出力を1つのモデルに備えたインダストリー4.0/IIoT対応

Problem-Solving Laser Measurement Sensor

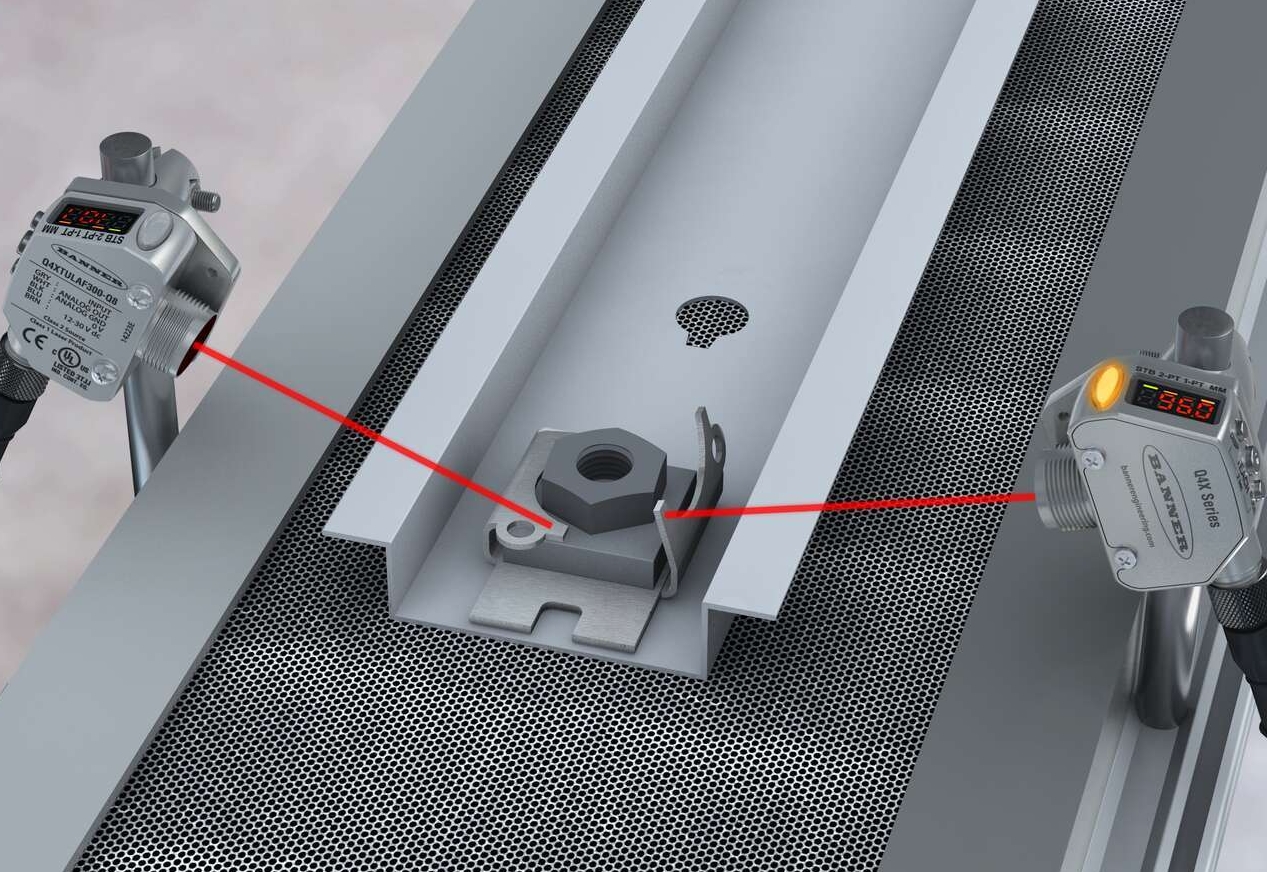

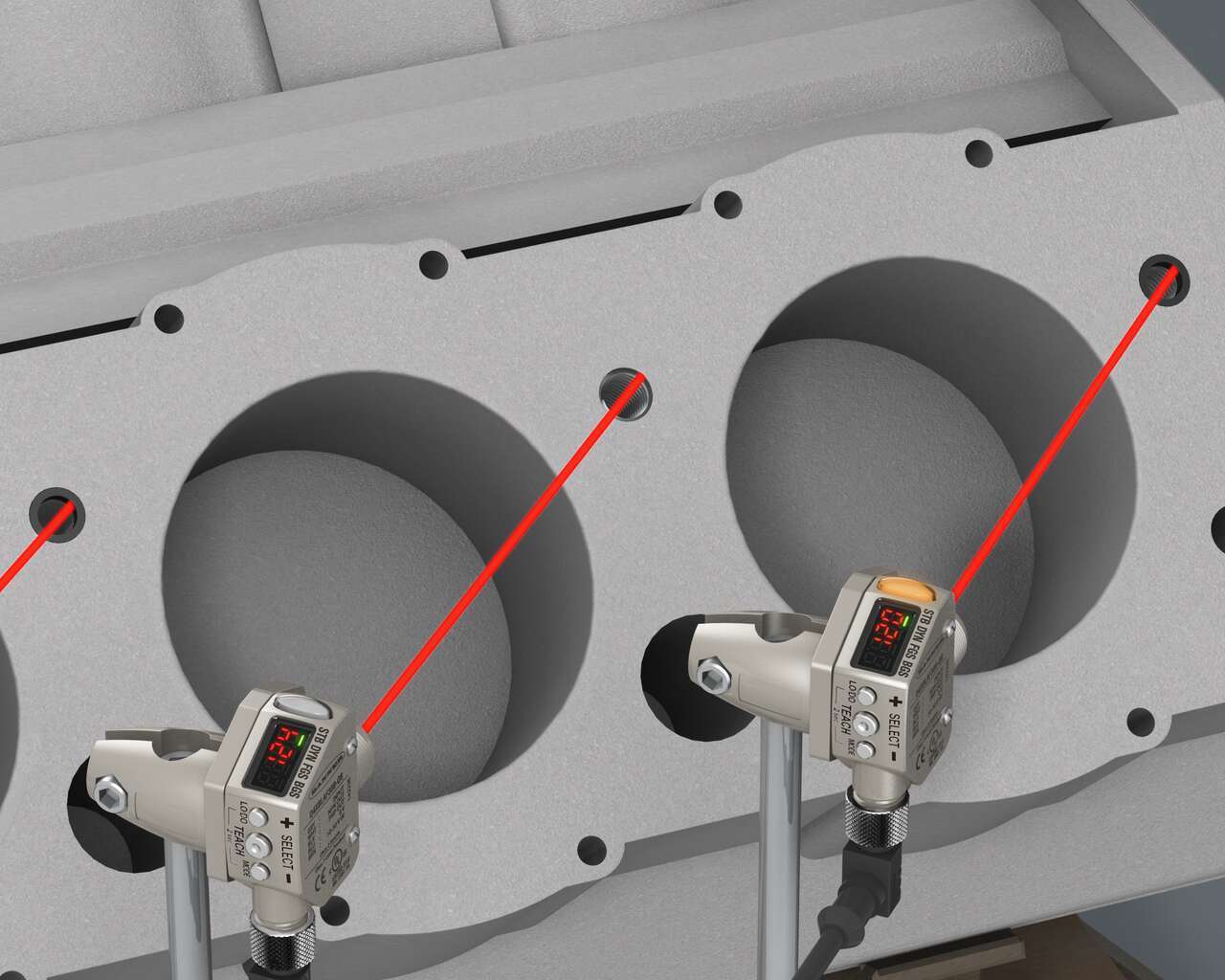

より高いパフォーマンスとミリメートル未満の距離の変化を検出できる能力を持つ、多用途性に優れた頑丈なレーザー距離センサです。

- ディスクリート、アナログ (0~10Vまたは4~20 mA)、透明体、およびIO-Linkモデル

- 25 mmから610 mmの確実な検出範囲

- 様々なターゲットの色、材質、および表面を距離に基づいて検出

- エラー防止用途に最適なデュアルティーチモード (明暗度 + 距離)。反射板を使用せずに透明体を検出

- FDA級ステンレス鋼製、IP69K等級の堅牢なハウジング