Safely Start and Stop Machines

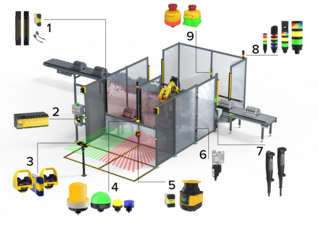

Safety and Indication for Machine Start/Stop

Operators must be able to safely start machine processes as well as safely stop them in an emergency using a variety of safety-rated devices including emergency stop buttons, rope pulls, and two hand control devices.

Banner Engineering combines ergonomic safety-rated devices with LED indication for a more intuitive user experience and at-a-glance visual management of your safety systems. Keep reading to learn about the different types of safe operator interfaces.

Emergency stop buttons (or e-stops) and rope pulls ensure safe stops in emergencies. E-stops are mechanical buttons that must be pressed with force to actuate. Pressing an e-stop, or pulling the rope on a rope pull, will immediately stop hazardous motion of the machine.

Two hand controls are devices that initiate machine processes, for example when operating a mechanical power press. The operator must have one hand on each control before the machine will safely start, and the machine will continue operation only as long as both hand controls are actuated. This ensures that the operator's hands are away from the point of operation during the entire time the machine is moving.

Please note: The information on this page is meant for educational purposes only and is accurate as of the time of publication. Always consult a safety expert about your specific application before implementing any machine safety measures.

Illuminated Base Quickly Identifies Pressed Button

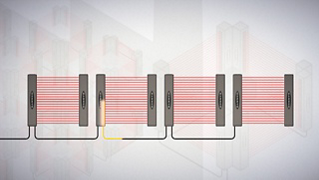

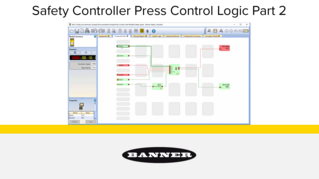

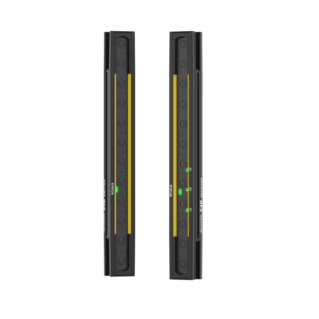

With traditional e-stops, it can be time-consuming to determine exactly which button was pressed, and typically an emergency stop condition requires a reset of all e-stop buttons on a line. To solve this challenge, illuminated e-stops have an LED base that can be configured to change from yellow to flashing red when pushed. The colored lights n the e-stop base provide easy visual indication of armed button, pushed button, or system status.

This makes it easy to quickly see the status of all estops at a glance and instantly identify an actuated button. The faster the response to the stop condition, the more quickly the machine can be restarted, reducing unplanned downtime. lluminated e-stops can also reduce commissioning time and costs due to the ability to series connect the e-stops to a safety controller. This not only reduces cable costs and wiring time, but also reduces the number of inputs used at the safety controller.

Quickly Identify Pull Rope with LED Indicator

Rope pull switches run along the length of a conveyor so the operator can grab and pull it from anywhere to immediately stop the conveyor. When the rope is pulled, it can often be difficult to locate the safety device in need of reset. To help the operation to return to normal quickly, a LED domed indicator can be mounted to the housing of rope pull switches for fast identification of the unit that was activated.

Spans of rope range from 6 m to 100 m, providing the flexibility to safeguard long or short conveyors. Rope pull switches from Banner are also made with heavy-duty thermoplastic housing for use in demanding industrial settings.

Start, Stop, and Indication Functions in One Ergonomic Solution

A run bar combines two hand control devices, e-stops, and indicators into a convenient ergonomic solution for operating machinery. The two-hand control system makes the operator a “hostage” while the hazard is present, preventing the operator from putting their hands in the way of the hazard.

Two hand control actuators must be located in a way that hazardous motion is completed or stopped before the operator can release one or both of the buttons and reach the hazard.

Emergency Stop for Conveyors & Large Machines

ローブ式非常停止スイッチはスチール製鋼線ロープと組み合わせて使用することで、コンベアや大型機械で非常停止を作動することができます。

- スパン範囲6~100 m

- トリップ式およびラッチ式スイッチモデルを選択可

- スイッチの寿命は1万回動作以上

- 過酷な環境に耐えるヘビーデューティー仕様のスイッチハウジング

- ロープが引かれてゆるんだり切れるとスイッチが作動

- ロープ式スイッチの強制乖離要件に適合

An Ergonomic Solution for Machine Start/Stop

両手操作式の作動および安全防護に役立つ、人間工学を考慮した堅牢なソリューション。DUO-TOUCH SG両手操作制御モジュールと接続して使用。

- 両手操作の作動に役立つ、便利で経済的なツール。DUO-TOUCH SG両手操作制御モジュールや同種の制御システムと接続して使用

- 手、手首、腕にかかるストレスを軽減する人間工学を考慮した設計

- 非常停止ボタンを備えたモデルも提供

- 電源,出力,故障を知らせる明るいLED表示

- ANSI B11.19およびISO 13851 (EN574) 規格に準拠

![Washdown Cover for Emergency Stop Buttons [Video]](/content/dam/banner-engineering/projects/video-thumbnails/E-Stop_Cover_Video_Thumbnail-new.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)