Vision Sensor

iVu Series

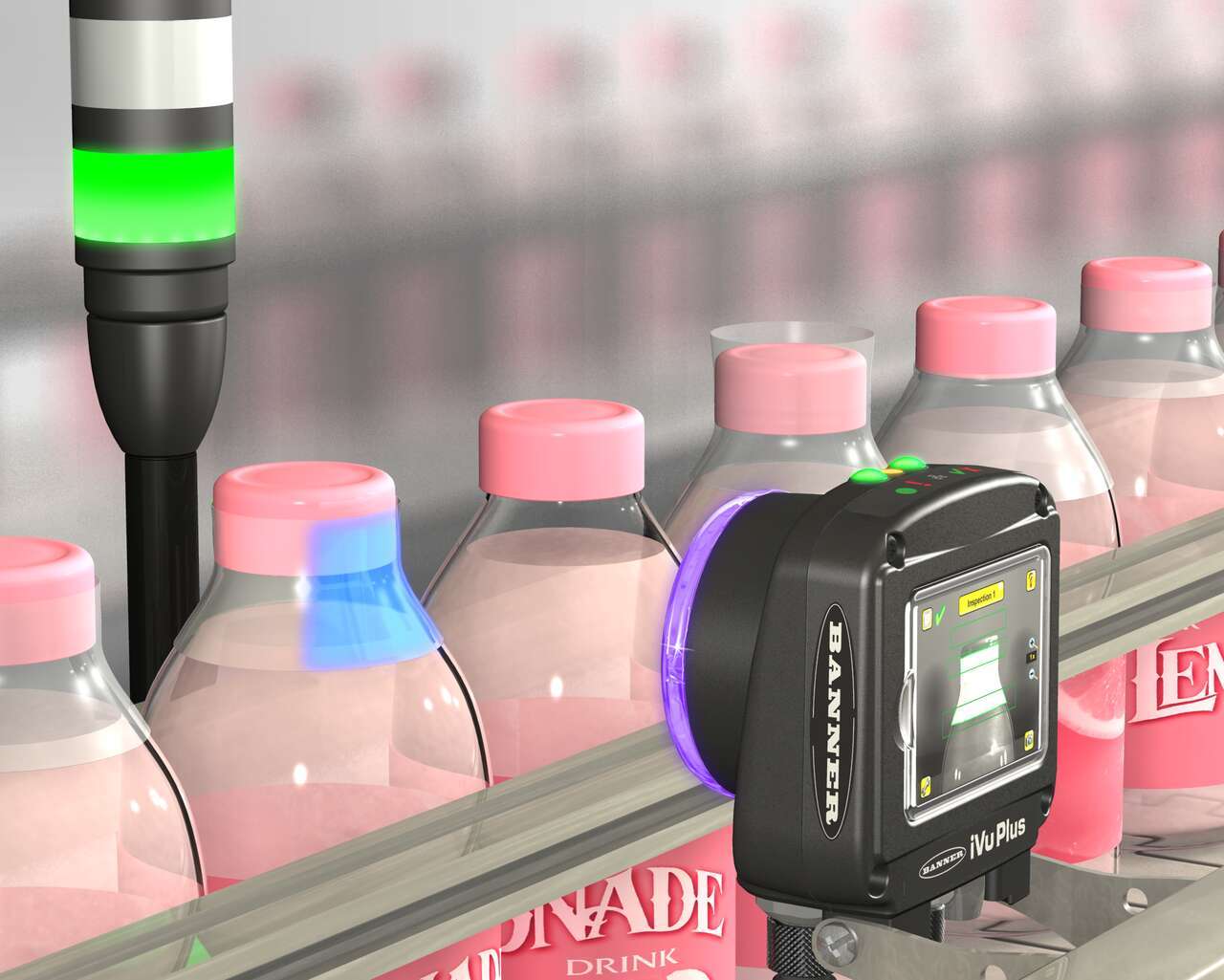

The iVu and iVu Color Image Sensors are used to monitor parts for type, size, orientation, shape, location, and color or color variations. The device can be set up and monitored using an integrated or remote touchscreen or with a PC. The following features are available:

- Setup, Manage, and Monitor iVu Series Devices with an Integrated or Remote Touchscreen or with a PC

- All-in-one solution with camera, controller, lens, and light included in one package

- Configure in minutes using Vision Manager PC software, onboard touchscreen display or using remote touchscreen to access to hard to reach places

- Highly capable image sensors to solve a wide range of vision applications, such as item detection, matching, part positioning or color verification

- Inspect multiple points with a wide variety of grayscale or color tools, depending on your application

- Compact, rugged, IP67 housing available with a variety of integrated ring lights including red, blue, green, white, infrared or UV

- Interchangeable lenses, including C-mount, for maximum application flexibility

- Factory communications (EtherNet/IP™, Modbus/TCP, PROFINET®, PCCC and Serial RS-232) for integration on the manufacturing floor

- Ability to change parameters on the fly with full runtime editing to reduce costly downtime

Downloads

Archived Software

Application Notes

-

-

文末検査

-

![Vent Tube Presence on Filler [Success Story]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2013/iVu-C-Mount-Remote-washer-Tube-Inspection.psd/jcr:content/renditions/cq5dam.web.1280.1280.jpeg)

Vent Tube Presence on Filler [Success Story]

-

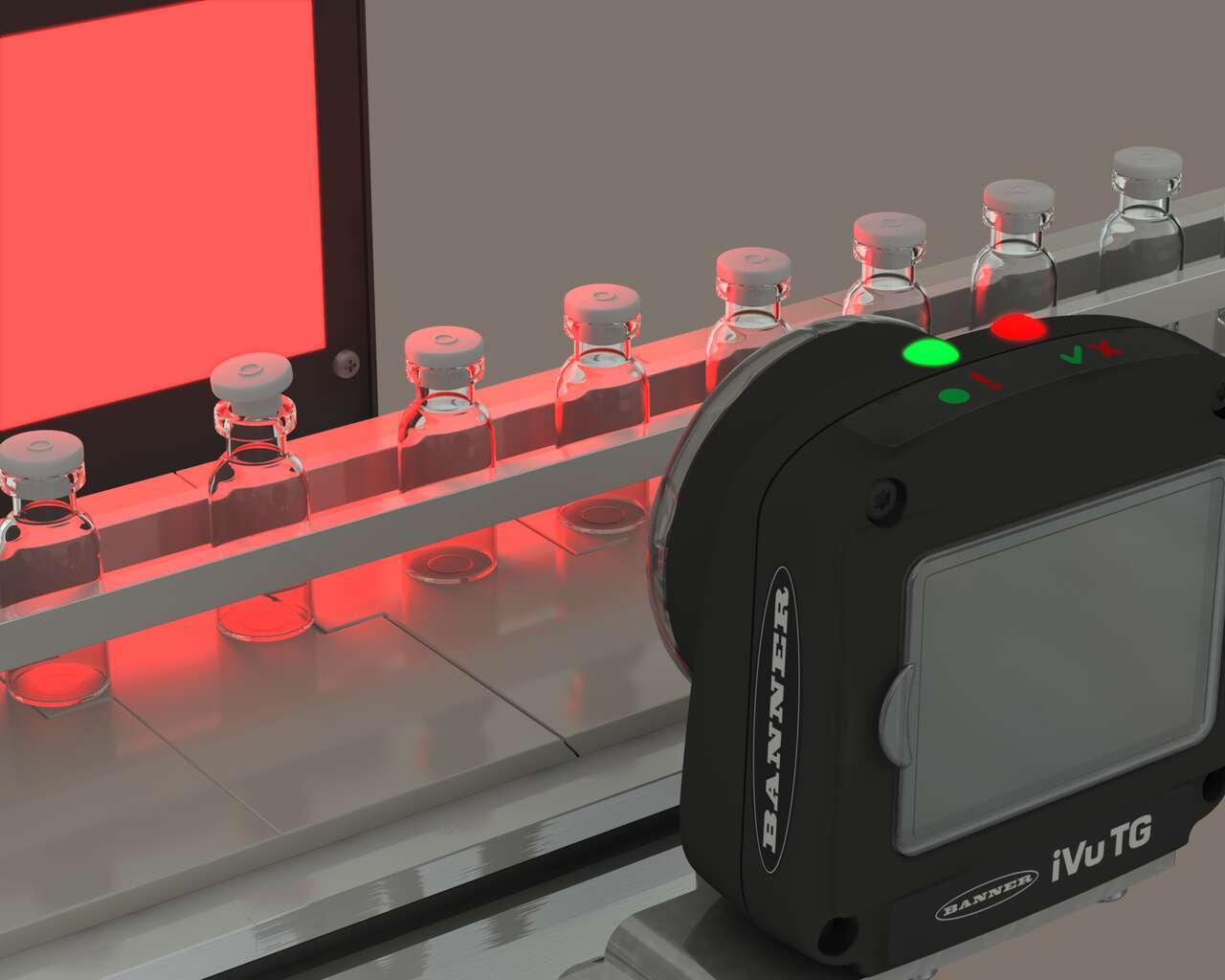

バイアル栓の密封検査

-

ブリスターパックの検査

-

ポケットテープに搭載された集積回路チップのエラー防止

-

電子マーク確認

-

![品質規格を満たすために使用する複合検査 [成功事例]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2013/iVu-PLUS-TG-Cap-and-Orientation-Inspect_Detergent.psd/jcr:content/renditions/cq5dam.web.1280.1280.jpeg)

品質規格を満たすために使用する複合検査 [成功事例]

-

工業用インテリジェントメールバーコードの読み取り

-

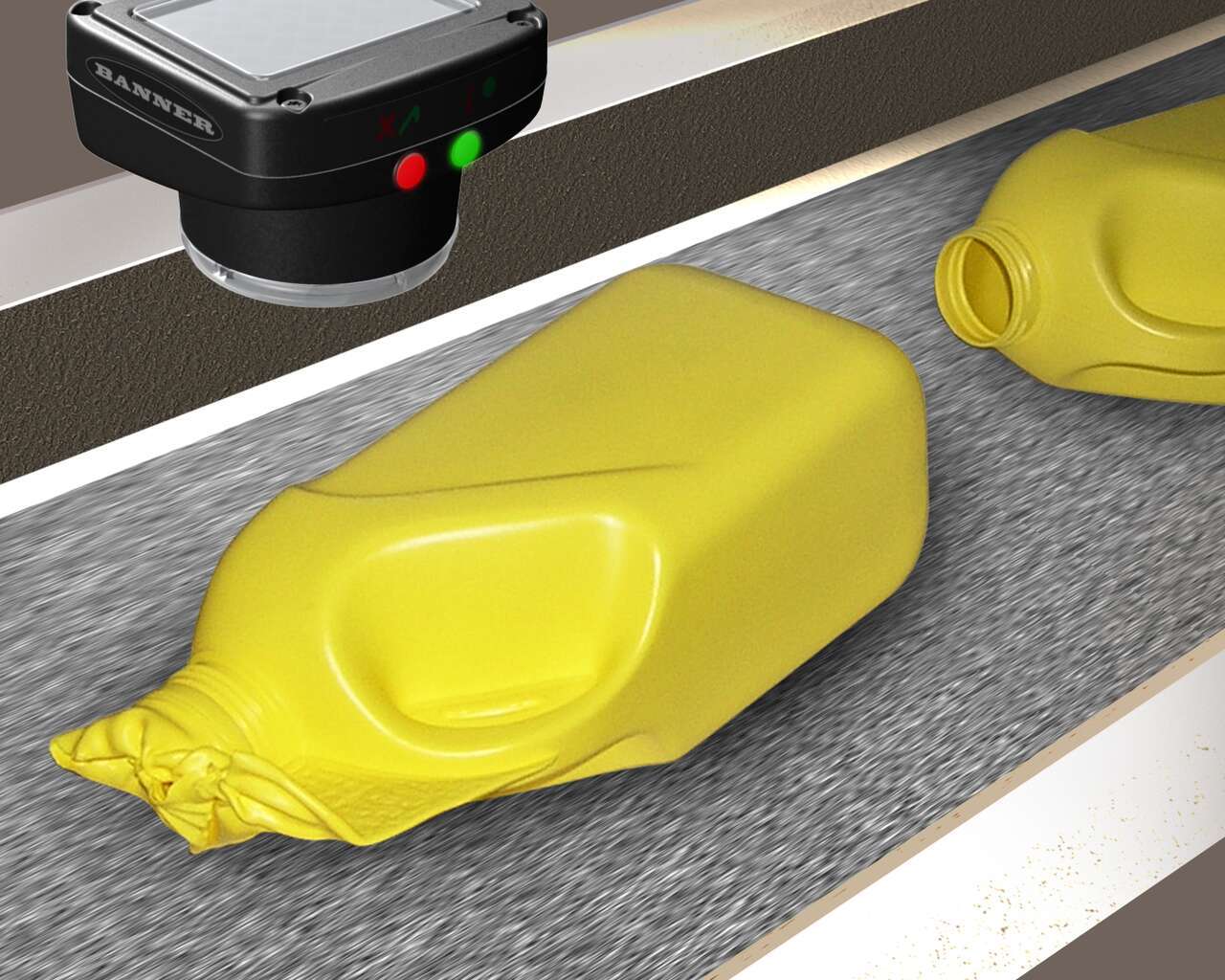

部品の向き

-

過酷な環境での小型部品検査

-

ラベル位置の検査

-

車両ドアパネルの部品の色検査

-

射出成形品の検査

-

ボトルキャップの有無と正しい色の検査

-

日付/ロットコードの検査

-

ドリル穴の検査

-

ラベル検査

-

パンチ穴の検査

-

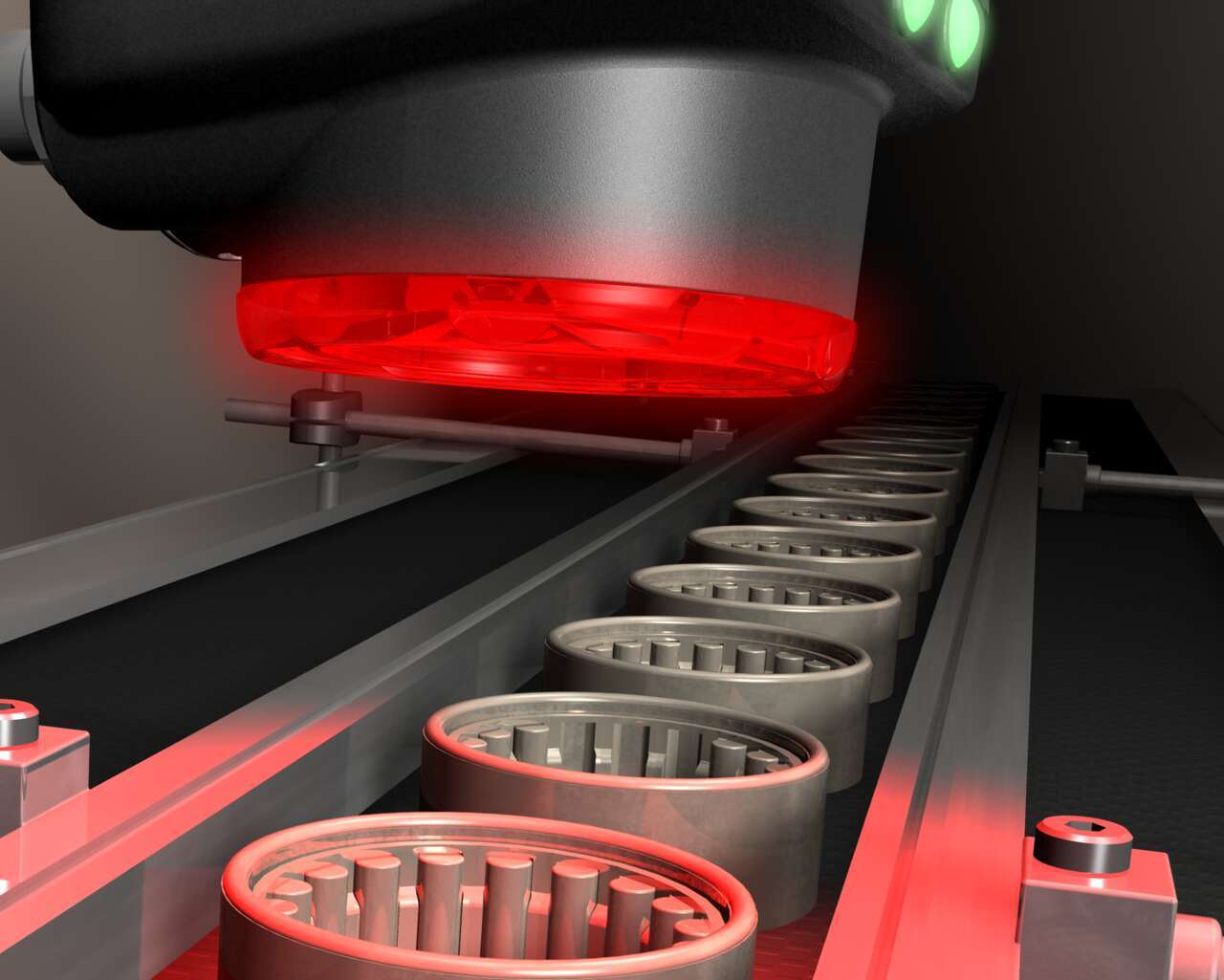

ベアリング検査

-

箱の内容物の検出

-

食料品パッケージのラベル検査

-

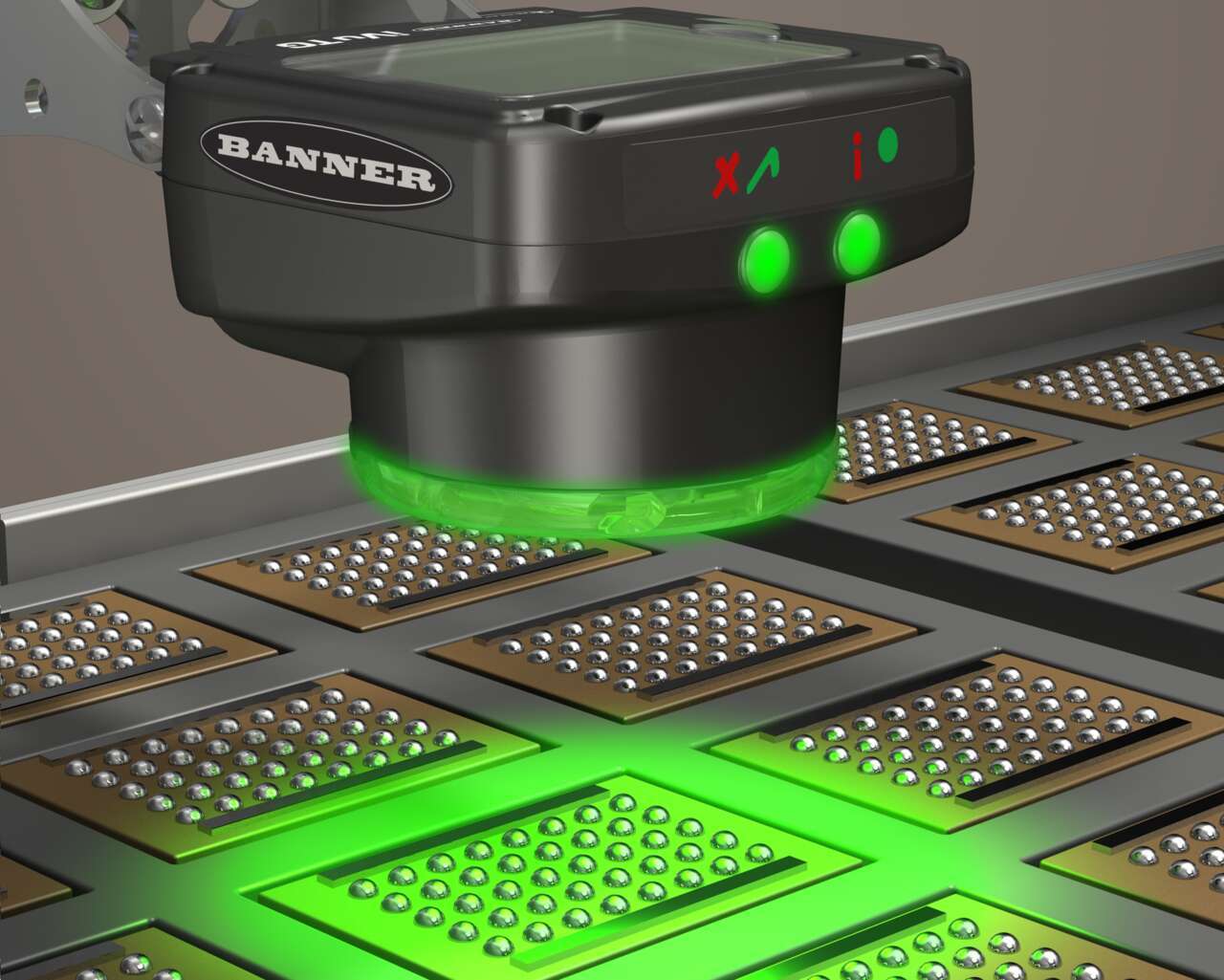

はんだボール検査

-

包帯の欠陥検出

-

向きの確認

-

ラベル検査

-

日付/ロットコード有無の検出

-

不正開封防止バンドの位置と有無の検知