すべてのワークステーションソリューション

-

組立ステーションからAGVへの回収要請

組立ステーションからAGVへの回収要請

• 完成したパレットを組立ステーションから迅速に回収 • 組立ステーションからAGVへ直接通信できる • 所要時間のデータを用いたプロセス効率の向上

-

繁忙なワークステーションのアセンブリタイマー

繁忙なワークステーションのアセンブリタイマー

IO-Link通信機能付きのK50 Proタッチボタンは、作業員の視界にタクトタイムを表示するため、組立作業のペースを維持し、生産目標を満たす上で役立ちます。

-

バーコードの読み取り

バーコードの読み取り

ABR Series barcode readers can be used to solve track and trace applications, offering increased resolution to read smaller codes, over a larger target area, and at greater distances. Polarization is now available in both 1.3 MP and 2 MP ABR 7000 models for improved performance on targets with reflective surfaces or where glare is present. Our highest resolution camera, the VE is also available in only-barcode reading models, as well as the original vision camera-only model. This makes our VE series is the highest-resolution barcode reader in our portfolio, designed to better solve complex applications.

-

ピックトゥライトソリューション

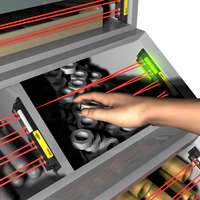

ピックトゥライトソリューション

Several technologies and solutions are available for bin-picking applications for error-proofing processes. Light arrays prompt the operator for part selection with integral job lights, then reliably sense retrieval of the part, using an array of visible red or infrared sensing beams located in front of the bin.

-

Part Pick Verification for Large Bins

Part Pick Verification for Large Bins

To reduce the risk of error in an assembly operation, a one-piece EZ-LIGHT PVD pick-to-light sensor is placed on the top rail of a shelf, looking down on the shelf opening. The PVD is interfaced with a process controller that is programmed to illuminate the PVD on the bin to pick. After the PVD detects that the assembler's hand has entered and left the bin, the controller signals the PVD on the next bin to pick.

-

小型ビン向けの部品選択表示

小型ビン向けの部品選択表示

To reduce the risk of error in an assembly operation, a one-piece EZ-LIGHT PVD pick-to-light sensor with a 400 mm range is interfaced with a process controller programmed with the correct assembly sequence. The controller makes the PVDs light up in the correct order, to show the assembler which part to pick. After the PVD detects that the assembler's hand has entered and left the bin, the controller signals the PVD of the next bin in the pick sequence to light up.

-

Bin Picking for Order Fulfillment

Bin Picking for Order Fulfillment

In a book packing warehouse, the rack above each carton of books is equipped with a one-piece EZ-LIGHT PVD pick-to-light sensor. A worker fills orders by selecting the quantity of each book specified on the packing slip. To make it easier for the worker to find the cartons from which to pick books, the PVDs above those cartons are illuminated. The PVD detects the workers hand in the carton to verify that the title was picked.

-

ワークステーション用高品質LED照明

ワークステーション用高品質LED照明

Banner’s WLB32 Industrial Light Bar is ideal for workstations. With a Hi/Lo/Off switch, operators are able to control the lighting level and are able to switch the LED light bar off when they are done. The WLB32 provides workers high brightness with even light output and enables numerous tasks in a workstation, including working on a computer.