Guarding Personnel at Meat Slicing Machine in a Harsh Environment

Application: Safeguarding meat slicing machine

Challenges: Harsh environment created by cleaning procedures

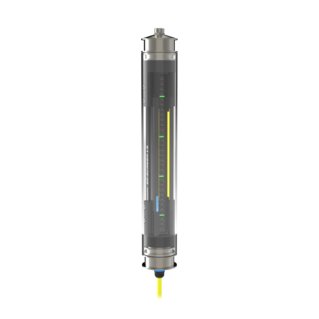

Solution: EZ-SCREEN LS safety light curtains in IP69K hygienic tubular enclosures

Benefits: Enclosures designed with a hygienic and sanitary design to protect from hot water and high-pressure spray

The blades of a meat slicer present a hazard to operators and steps must be taken to prevent workers from injuring their hands. Safety light curtains recognize if an individual’s hand is entering the machine while in operation and initiates a stop function. The main challenge of a meat slicer machine is that it is subjected to frequent cleanings. This can prove difficult because typical light screens have numerous crevices and corners that collect debris and can be difficult to clean. Safety light screens on food lines need to be protected from water ingress and damage while remaining easy to clean to meet FDA standards.

Smooth Enclosures Protect Light Curtains from Harsh Environment

The EZ-SCREEN LS light curtains in hygienic tubular enclosures successfully protect operators from injury and remain hygienic for easy cleaning procedures. They are FDA compliant and made with shatterproof polycarbonate tubes and 316L stainless steel endcaps and brackets. The enclosures have a smooth surface that minimizes build up and assists easy cleanup of debris.

The meat slicer machine is frequently exposed to chemical cleaning agents and high-pressure washdowns. The IP67/IP69K rated enclosures withstand a large variety of common cleaning agents and the polycarbonate housing will not discolor or become cloudy over time, ensuring reliable performance and a long lifespan.

The EZ-SCREEN LS safety light curtains in hygienic tubular enclosures are available with remote fixed blanking on select models. This additional feature gives the curtains the capability to ignore objects, such as the conveyor, while still protecting operators from injury.