- All-in-one design eliminates the time, labor, and expense of installing separate sensors and nodes

- The Q45PSD all-in-one pressure sensor measures pressure to maintain efficiency, safety, and productivity while reducing energy costs

- The Q45DEW all-in-one dew point sensor monitors dew point, humidity levels, and temperature to help protect tools and machinery from harmful condensation

- The Q45DT all-in-one wireless dual thermistor node measures two separate thermistors for air- and liquid-handling applications

- The Q45CT all-in-one current transformer and wireless node measures current draw, helping to reveal issues with critical motor performance

- The Q45VA all-in-one vibration and temperature sensor and wireless node monitors the health and performance of motors, pumps, and similar equipment with rotating motion; mounting kit with magnetic and non-magnetic brackets available; available in C-cell battery power supplies

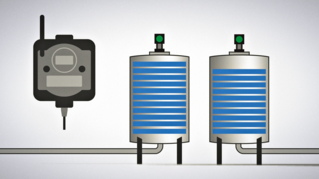

- The Q45UA all-in-one ultrasonic sensor and wireless node monitors the level or position of fluid or dry assets in tanks, totes, and containers

- The Q45TA all-in-one thermistor node measures temperature in key areas or processes

- The Q45THA all-in-one temperature and humidity and wireless node monitors environmental conditions in a variety of applications

- Use with Cloud Data Services software to create an end-to-end IIoT solution that will help you identify and resolve problems more quickly and make better, data-driven decisions

Marketing Literature

Marketing Literature

Technical Documents

Technical Literature

Software

Solutions Guide

Technical Notes

Videos

![Vibration Monitoring & Predictive Maintenance [Video]](/content/dam/banner-engineering/video/video-thumbnails/products/Vibration%20Sensor%20Product%20Thumbnail.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

Vibration Monitoring & Predictive Maintenance

Use the new vibration sensor for monitoring vibration and temperature with Banner's wireless products for a complete monitoring solution.

Q45VA Mounting Tutorial

Learn four different ways to mount the Q45VA Wireless Vibration and Temperature Sensing to monitor machine health.

Remote Tank Level Monitoring for Industrial Applications

Prevent your operations from being unexpectedly disrupted because of an empty tank with Banner’s tank monitoring solution.

Application Notes

Condition Monitoring: Predictive & Preventative Maintenance

Identify machine problems before they cause serious damage or unplanned downtime.

Predictive Maintenance for Crane Motors and Gearboxes

Wireless products enable predictive maintenance in the port industry. Motors and gearboxes on cranes are prone to high vibration and temperature which can cause them to degrade. Predictive maintenance allows employees to interfere and solve problems before they completely fail and cause unplanned downtime and lost profit.