Analog Laser Measurement Sensor Selection

Laser measurement sensors from Banner Engineering solve a wide variety of analog applications. Our portfolio of laser sensors includes powerful problem solving, high accuracy, high precision, and long range sensors that are also available with IO-Link communication. Compare the analog sensors find the right solution for your application. Or watch the video to learn how smart sensors from Banner solve more applications, save inventory costs, and prevent unplanned downtime.

Comparison Chart

* LTF analog resolution and linearity based on 1 σ

Best Selling

Q4X Series Rugged Laser Distance Sensor

Superior performance, detecting sub-millimeter changes in distance. FDA-grade stainless steel housing.

Key Features

25 mm to 610 mm range

0.15 mm to 1.75 mm analog resolution

±0.25 mm to ±25 mm linearity

IP69K

Integral QD connection

18 mm: 57.4 mm x 18 mm x 43.6 mm

Flush: 57.4 mm x 18 mm x 32.5 mm

Starting At: $ USD

Learn More →

High Precision

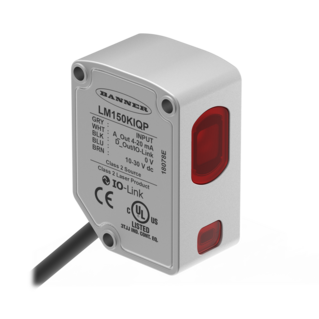

LM Series Precision Measurement Sensor

Best in class performance with increased stability, reliability and precision for real world targets.

Key Features

40 mm to 150 mm range

0.002 - 0.004 mm analog resolution

±0.02 mm to ±0.07 mm linearity

IP67

Pigtail QD connection

48.5 mm H x 23.5 mm W x 35.8 mm D

Starting At: $ USD

Learn More →

Mid-Range

Q5X Series High Power, Multi-Function Laser Sensor

Laser triangulation sensor with industry-standard rectangular housing reliably detects challenging targets.

Key Features

95 mm to 3 m range

1 mm to 30 mm analog resolution

±5 mm to ±150 mm linearity

IP67

Integral QD connection

60 mm H x 25 mm W x 52 mm D

Starting At: $ USD

Learn More →Best Selling

High Precision

Mid-Range

Superior performance, detecting sub-millimeter changes in distance. FDA-grade stainless steel housing.

Best in class performance with increased stability, reliability and precision for real world targets.

Laser triangulation sensor with industry-standard rectangular housing reliably detects challenging targets.

Key Features

25 mm to 610 mm range

0.15 mm to 1.75 mm analog resolution

±0.25 mm to ±25 mm linearity

IP69K

Integral QD connection

18 mm: 57.4 mm x 18 mm x 43.6 mm

Flush: 57.4 mm x 18 mm x 32.5 mm

Key Features

40 mm to 150 mm range

0.002 - 0.004 mm analog resolution

±0.02 mm to ±0.07 mm linearity

IP67

Pigtail QD connection

48.5 mm H x 23.5 mm W x 35.8 mm D

Key Features

95 mm to 3 m range

1 mm to 30 mm analog resolution

±5 mm to ±150 mm linearity

IP67

Integral QD connection

60 mm H x 25 mm W x 52 mm D

High Accuracy

LE Series 1 m Range Laser Displacement Sensor

High level of measurement accuracy, suitable for controlling, sorting, and inspection tasks in quality control.

Key Features

100 mm to 1000 mm range

0.02 mm to 1 mm analog resolution

±0.375 mm to ±4.5 mm linearity

IP67

Integral QD, pigtail QD, and cable connections

60 mm H x 26 mm W x 56 mm D

Starting At: $ USD

Learn More →

Long Range

LTF Series Long-Range Time-of-Flight Laser Sensor

Detects targets regardless of color, material or sheen from up to 24 meters away, straight-on or at an angle.

Key Features

50 mm to 24000 mm range

0.3 mm to 4 mm analog resolution*

±10 mm to ±25 mm linearity*

IP67

Integral QD and pigtail QD connections

77 mm H x 26 mm W x 56 mm D

Starting At: $ USD

Learn More →High Accuracy

Long Range

High level of measurement accuracy, suitable for controlling, sorting, and inspection tasks in quality control.

Detects targets regardless of color, material or sheen from up to 24 meters away, straight-on or at an angle.

Key Features

100 mm to 1000 mm range

0.02 mm to 1 mm analog resolution

±0.375 mm to ±4.5 mm linearity

IP67

Integral QD, pigtail QD, and cable connections

60 mm H x 26 mm W x 56 mm D

Key Features

50 mm to 24000 mm range

0.3 mm to 4 mm analog resolution*

±10 mm to ±25 mm linearity*

IP67

Integral QD and pigtail QD connections

77 mm H x 26 mm W x 56 mm D

Key Terms

Resolution

The smallest change in distance a sensor can detect. A resolution of 0.5 mm means that the sensor can detect changes in distance of 0.5 mm.

Linearity

How closely a sensor’s analog output approximates a straight line across the measuring range. The more linear the sensor’s measurements, the more consistent the measurements across the full range of the sensor. Linearity of 0.5 mm means that the greatest variance in measurement across the sensor’s range is ± 0.5 mm.