All Material Handling Solutions

-

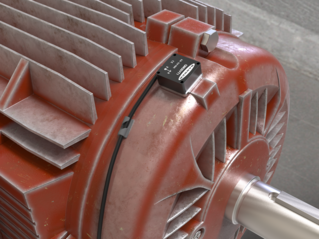

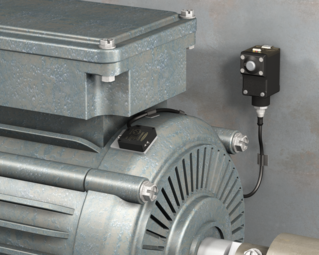

Wireless Motor Temperature Control and Monitoring

Wireless Motor Temperature Control and Monitoring

Instead of installing I/O transmission cabling, use a 10 to 30V dc powered Sure Cross Node and a Banner T-GAGE temperature sensor. When using host control systems, the Sure Cross Gateway transmits the temperature to the plant control room using a digital output related to temperature setpoints within the sensor. The motor is powered down or up based on these temperatures. When using a Gateway Pro as the wireless master device, the data ca be logged and alerts sent out to notify maintenance personnel when a motor is performing outside expected parameters.

-

Controlling Temperature and Humidity for a Cabinet Maker

Controlling Temperature and Humidity for a Cabinet Maker

A large cabinet maker needs to monitor and control the temperature and humidity throughout many rooms in a large production facility. Manual environmental readings of the entire plant were conducted periodically throughout the week. These manual readings only provided a snapshot of information and gathering the data took more than three hours. The customer did not have real-time, accurate information that could be used to control the plant environment. Manually collecting this information and controlling the fan system was timeconsuming and resulted in errors that damaged wood in storage, work in progress, and finished cabinets.

-

Machine Monitoring/Overall Equipment Effectiveness

Machine Monitoring/Overall Equipment Effectiveness

• Expand available data beyond local indication • Gather information necessary to react quickly • Drive efficiency improvements based on data previously unavailable

-

Equipment Monitoring from a Supervisor's Station

Equipment Monitoring from a Supervisor's Station

Provide at-a-glance machine status indication and send machine status information to a wide range of devices.

-

Environmental Monitoring inside a Machine Control Panel

Environmental Monitoring inside a Machine Control Panel

Identify small problems before they become major issues that impact machine performance and uptime.

-

Condition Monitoring: Predictive & Preventative Maintenance

Condition Monitoring: Predictive & Preventative Maintenance

Identify machine problems before they cause serious damage or unplanned downtime and alert staff of changes in condition via text message or email as well as provide at-a-glance local indication of machine status.

-

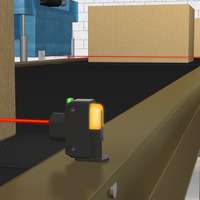

High Speed Package Profiling with Laser Sensors

High Speed Package Profiling with Laser Sensors

3 Apr 2019A laser measurement solution enables high-speed package sorting in order fulfillment applications and helps drives failure rates down—ultimately saving costs and maximizing profits.

-

Safeguarding Access Points to a Depalletizer

Safeguarding Access Points to a Depalletizer

An LS Series safety light curtain with a mute arm kit in T-configuration combined with an XS26 Series safety controller is an easy-to-implement solution that protects staff from potential hazards without disrupting the flow of pallets to the depalletizer.

-

Safeguarding a Pallet Transfer Conveyor

Safeguarding a Pallet Transfer Conveyor

Pallet transfer conveyors are used to move heavy loads to the shipping area. Both the pallets and the conveyor pose risks for accident and injury and must be safeguarded. An SX5-B safety laser scanners safeguards the loading and unloading stations on the conveyor and enables a continuous flow of pallets through the system.

-

Barcode Reading

Barcode Reading

ABR Series barcode readers can be used to solve track and trace applications, offering increased resolution to read smaller codes, over a larger target area, and at greater distances. Polarization is now available in both 1.3 MP and 2 MP ABR 7000 models for improved performance on targets with reflective surfaces or where glare is present. Our highest resolution camera, the VE is also available in only-barcode reading models, as well as the original vision camera-only model. This makes our VE series is the highest-resolution barcode reader in our portfolio, designed to better solve complex applications.

-

Tracking of Received Goods

Tracking of Received Goods

Banner’s ABR barcode readers ABR Series barcode readers with a 2MP (1600 x 1200 pixels) imager reliably read small or complex barcodes, even at large distances or field of views, helping maintain accountability and an efficient flow of packages throughout a distribution center. The ABR barcode reader is ready to scan right out of the box with SMART TEACH push button for teaching codes directly on the device.

-

Reading Multiple 1D and 2D Barcodes

Reading Multiple 1D and 2D Barcodes

Barcode position can change with the location of each box on a conveyor and the height of the boxes can vary. An ABR 7000 barcode reader decodes multiple 1D and 2D barcodes over a large area in a single inspection, regardless of position or orientation.

-

Tracking Products through Packaging

Tracking Products through Packaging

Barcodes used to track packaged produce through the supply chain contain important product information that must be verified at multiple points during packaging. An ABR 3000 barcode reader ensures that the barcode on each package is present and correct.

-

Order Fulfillment: Wide Shelf

Order Fulfillment: Wide Shelf

Each wide shelf is equipped with a one-piece EZ-LIGHT PVD pick-to-light sensor in retroreflective mode, which has a range of up to 2 m. The PVD lights up on the bin from which the worker should select the map to ship.

-

Bin Picking for Order Fulfillment

Bin Picking for Order Fulfillment

In a book packing warehouse, the rack above each carton of books is equipped with a one-piece EZ-LIGHT PVD pick-to-light sensor. A worker fills orders by selecting the quantity of each book specified on the packing slip. To make it easier for the worker to find the cartons from which to pick books, the PVDs above those cartons are illuminated. The PVD detects the workers hand in the carton to verify that the title was picked.

-

Light-Guided Kit Building at Large Station

Light-Guided Kit Building at Large Station

Manual kit building at large stations can be time-consuming and subject to human error, especially if storage racks are difficult to navigate. The PTL110 series pick-to-lights are scalable for large systems and highly versatile to complete numerous tasks.

-

Pick-to-Light Accelerates Final Assembly and Order Fulfillment

Pick-to-Light Accelerates Final Assembly and Order Fulfillment

Learn how a golf equipment manufacturer recently used PTL110 pick-to-light devices to simplify and accelerate their final product assembly and order fulfillment processes.

-

Improving Productivity with Pick-to-Light Products

Improving Productivity with Pick-to-Light Products

Learn how eFlex Systems empowered a hydraulic pump manufacturer with its turn-key platform and Banner's PTL110 pick-to-light devices to improve productivity and reduce errors in their assembly processes.

-

High-Quality LED Lighting for Workstations

High-Quality LED Lighting for Workstations

Banner’s WLB32 Industrial Light Bar is ideal for workstations. With a Hi/Lo/Off switch, operators are able to control the lighting level and are able to switch the LED light bar off when they are done. The WLB32 provides workers high brightness with even light output and enables numerous tasks in a workstation, including working on a computer.

-

Highly Bright Illumination in Workstations

Highly Bright Illumination in Workstations

Banner’s WLS28 Work Light Strips with ON/OFF switches provide an energy-efficient solution for illuminating work areas and enclosure interiors with intense, long-lasting light. These LED lighting strips provide even, extremely bright illumination, and can easily fit in limited space setups. The work lights can be plugged into any local power source for simple operation.

-

Low-Bay LED Lighting

Low-Bay LED Lighting

The heavy-duty, energy-saving WLB92 from Banner Engineering provides an extremely bright lighting solution that provides consistent lighting across a warehouse. Since the LED factory light is so bright and gives a uniform output, fewer lights are needed in total, helping reduce the overall cost of lights and installation time.

-

Illuminated Forklift Guidance

Illuminated Forklift Guidance

The WLS27 Pro with discrete control and configured by Banner’s Pro Editor software is one of two new models of the WLS27 Pro series strip light. It now includes programmable RGBW LEDs for use in illumination, indication and inspection applications. Learn how the configurable WS27 Pro provided forklift guidance for warehouse operators.

-

Bright LED Indication on Automatic Industrial Doors

Bright LED Indication on Automatic Industrial Doors

Star Equipment uses Banner's WLS27 multicolor LED strip lights with EZ-STATUS™ with their automated industrial doors for safer, more efficient movement in the workplace.

-

Operator Guidance Indication

Operator Guidance Indication

Learn how a facility used WLS15 Pro with PICK-IQ to improve picking processes.

-

Operator Indication on Conveyor Systems

Operator Indication on Conveyor Systems

Learn how a facility used the K30 Pro Touch Button to improve operator control and guidance.

-

Box Sealer Status Indication

Box Sealer Status Indication

A solution was needed to better indicate a variety of complex statuses coming from a labeling machine. Banner's CL50 Pro column lights are an effective way to provide at-a-glance status indication.

-

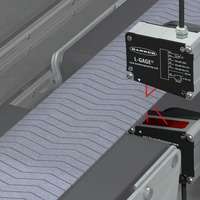

Measuring Wear Patterns on Conveyor Belts

Measuring Wear Patterns on Conveyor Belts

Elevators, escalators and moving sidewalks are major investments in any facility’s infrastructure. This equipment is expected to operate safely and reliably for many years and with minimal downtime for maintenance. To meet these expectations, a large-scale manufacturer of vertical and conveyor transport equipment performs rigorous tests on all system components. The data that is collected helps the company estimate component life expectancy and plan service schedules.

-

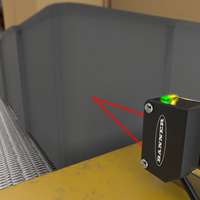

Long-Range Position Detection

Long-Range Position Detection

In a warehouse, the time-of-flight L-GAGE LT7 laser sensor gauges the position of a retrieval shuttle as far as 250 m away from the sensor.

-

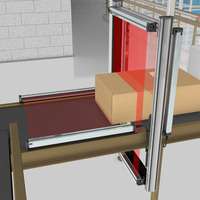

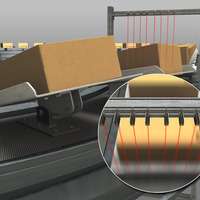

Detailed Inspection on a Sortation Conveyor

Detailed Inspection on a Sortation Conveyor

In large distribution facilities, sortation trays deliver products to the proper bin for correct shipment. Before sorting can begin, each tray needs to be empty so that items can be placed on the conveyor and sent to the next location. The 5mp VE Smart Camera recognizes very fine levels of detail and can detect items of almost any size, confirming the presence or absence of items on the trays.

-

Tracking Package Location through Conveyor Roller Gaps

Tracking Package Location through Conveyor Roller Gaps

• Precise location detection • High-speed conveyor • Customer specific product

-

Warehouse Vehicle Detection with Indication

Warehouse Vehicle Detection with Indication

Vehicle detection at loading docks is complicated because sensing solutions are exposed to the elements and need to recognize a wide variety of surfaces. Rugged ultrasonic sensors work well to accurately detect the surfaces of delivery vehicles regardless of the material. Pairing with bright LED indication creates unmistakable operator guidance.

-

Vehicle Detection and Indication at Outdoor Docking Station

Vehicle Detection and Indication at Outdoor Docking Station

Detecting trucks and signalling arrival, wireless communication.

-

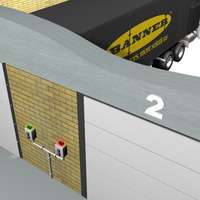

Monitoring Arrival and Departure of Trucks at a Loading Dock

Monitoring Arrival and Departure of Trucks at a Loading Dock

Sensor solution for outdoor truck detection for safety prevention purposes.

-

Delivery Truck Detection at an Outdoor Loading Dock

Delivery Truck Detection at an Outdoor Loading Dock

Automated solution to help alert workers of a delivery truck's arrival through the use of shifts in magnetic fields.

-

Loading Dock Monitoring and Truck Presence Indication

Loading Dock Monitoring and Truck Presence Indication

Sensor solution to signal the presence of a truck at a dock door with bright illumination.

-

Inbound and Outbound Status Indication at Loading Dock

Inbound and Outbound Status Indication at Loading Dock

In a recent material handling application, facility managers needed to find a solution that would alert them to the status of trailer capacity at loading dock doors in real-time.

-

Carton Dimensioning

Carton Dimensioning

Banner’s EZ-ARRAY measuring light curtains detect items as small as 5 mm wide with an edge resolution of 2.5 mm, and have high excess gain for detecting opaque objects. These features allow for reliable detection and measurement of packages that pass through the light curtains. The total number of beams blocked for each pair indicates the size, which is sent to a sorter as an analog signal. A PLC then diverts each carton to the appropriate storage location.

-

Extendable Reach Conveyor

Extendable Reach Conveyor

Banner provides sensing and industrial LED lighting solutions to help minimize carton and product damage inside a container. Banner’s QS18FF with background suppression has a fixed range of up to 100 mm with an 850 microsecond response time, allowing for easy detection of the packages/cargo and ensuring the extendable conveyor does not crush cartons. Banner’s WLB32 is a cost-effective, LED lighting solution available in AC and DC versions with a high lumen output that ensures proper illumination.

-

Shuttle Tote Positioning

Shuttle Tote Positioning

The Q20 WORLD-BEAM Polarized Retro sensors are mounted on the rails of the multishuttles, to confirm that product stays within the safety zone and confirms a product is positioned correctly to avoid hanging off the “safe zone.” Q20 sensors are cost effective and accurately detect presence and placement, making them ideal for a warehouse environment. The compact size and ease of installation make the Q20 a robust product for these applications. The Q20 sensors have a distance range up to 4 m and the sensor functionality of noise immunity and cross-talk avoidance allows the operator to test the system before use.

-

Wireless Forklift Signaling

Wireless Forklift Signaling

Banner’s Q45 wireless call sensor communicates to a wireless DX80, signaling that forklift drivers can remove the completed pallet for shipping. This helps keep the conveyor clear, keep it moving faster and leads to more productivity. Since forklift drivers are being called to action more quickly, it allows for more productivity.

-

Full Tote Indication and Verification

Full Tote Indication and Verification

In order to properly identify and use visual management, a sensor is triggered when the bag is full and then sends a signal to a K50 touch button to light red, which represents a full tote. The K50 touch visually shows operators the bag needs to be removed and changed with an empty one. In order to show the bag is ready for more packages, the operator presses the ergonomic K50 touch button, changing it back to green to show the bag is ready for more packages.

-

Exit Chute Jam Indication

Exit Chute Jam Indication

Banner’s Q30FF600 background suppression sensor confirms when a product enters the exit chute to ensure it came off the sortation system and that there isn’t a jam in the product chute. The Q30FF600 has long range sensing up to 600 mm, which is the standard width of many chutes.

-

Presence and Absence Item Detection

Presence and Absence Item Detection

A VE Series Smart Camera is an ideal solution to be able to detect the presence or absence of an object. The camera comes in a 5MP resolution giving a precise detection of objects. The VE reduces costly downtime facilitating fast product changeover. With its robust metal housing and optional lens covers the VE can be used in harsh environments where heat, vibration, and moisture exist.

-

Sortation Auto Induction Station

Sortation Auto Induction Station

S18-2 retroreflective sensors provide long-range, effective sensing along an auto-induct conveyor station. Polarized sensors can help with shiny surfaces by reducing false triggers. The S18-2 retroreflective sensors are cost-effective sensors with a barrel mount style, making them easy to install along a conveyor for verification purposes and are available in retroreflective, thur-beam, diffuse or fixed-field models.

-

Stacker Crane Positioning

Stacker Crane Positioning

Banner’s time-of-flight LT7 laser sensors provide long-distance ranges up to 250 m with a visible red laser spot for easy alignment. Depending on range needed, a diffuse or retroreflective time-of-flight laser sensor can be used. Retroreflective LT7 laser sensors provide ranges up to 250 m and diffuse LT7 laser sensors provide long-range background suppression up to 10 m.

-

Parcel Collision Avoidance

Parcel Collision Avoidance

Banner’s DS18 sensor coupled with a zone control modules offers a cost-effective solution that gives an output and shows a change in state for optimal flow of products. This helps prevent box collisions and stops the zone so contents of packages are preserved.

-

Accurate Pallet Detection

Accurate Pallet Detection

Banner’s PVD100 is a custom-made solution that accurately detects pallets without adjustments, even when features are inconsistent. This easy-to-use, versatile light screen has a wide beam pattern, making alignment simple. With a compact design, it can easily be embedded into a machine or directly on the line. The PVD100 light screen sensing solution has a detection height of 100 mm and a scanning range of 2 m. It has highly visible red and green LED lighting to display operation and indicate

-

Emergency Stop Buttons on a Conveyor

Emergency Stop Buttons on a Conveyor

Banner’s 30 mm mount E-Stop buttons work well in this type of application because they have an illuminated base that turns from yellow to flashing red when actuated. The red flashing illumination of the E-stop button visibly alerts operators which button was pressed so they can quickly and easily fix the problem to reduce down time and only reset the button that was activated.

-

Traffic Control at Loading Docks

Traffic Control at Loading Docks

EZ-LIGHT Traffic Lights are mounted at each bay to visually signal to drivers when they have permission to back into the loading dock. The lights are preassembled, with up to three indicators and three colors in one housing, making them cost effective and easy to install. Traffic Lights are an ideal solution for outdoor applications, with intense levels of light output and included sun shields.

-

Replacing Cables on a Transport Cart

Replacing Cables on a Transport Cart

Transport carts typically use a conductor cable for operation, which breaks over time and causes production delays and increased maintenance costs. Controlling transport carts wirelessly reduces these issues.

-

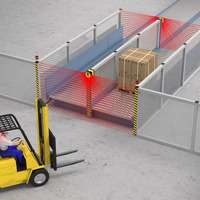

Pallet Transfer Safeguarding

Pallet Transfer Safeguarding

Due to the dangers associated with a full pallet transfer, horizontal area guarding is needed in order to maximize productivity of packaging while protecting operators from the hazardous motion of a machine.

-

Detecting Pallets with Irregular Loads

Detecting Pallets with Irregular Loads

An ultrasonic sensor will provide reliable pallet detection. Ultrasonic sensors emit sound waves and “listen” for the return echo of the sound wave bouncing off the target. The sensor can be taught a reliable background, in this case the conveyor, and will listen for sound waves returning from the conveyor. Any object getting between the sensor and the conveyor will be detected, causing the output to switch.

-

Automatic Storage & Retrieval System

Automatic Storage & Retrieval System

SureCross FlexPower™ Nodes and low-power sensors combine to create a portable monitoring system that instantly integrates with existing Automatic Storage and Retrieval System (AS/RS) cranes. The combination of Banner’s reliable wireless solution and unique power management capability creates a host of simplified monitoring applications onboard the AS/RS crane. The FlexPower battery pack supplies power to the Node and up to four low-power sensors for years of operation. Preventative maintenance concerns can be addressed with a FlexPower Node equipped with multiple thermocouples for monitoring motor or critical bearing temperature. The communication output on the Gateway (system controller) can be used to create historical logs or trends to verify the equipment is operating at peak performance. Crane motion can be announced to staff with an EZ-LIGHT™ indicator at the end of each aisle. This bi-directional monitoring system is a simple way to alert employees that a crane is in motion without requiring any new construction or expensive downtime.

-

Carton Sizing

Carton Sizing

Cartons moving on a conveyor pass between three pairs of EZ-ARRAY measuring light curtains. The total number of beams blocked for each pair indicates the size, which is sent to a sorter as an analog signal. A PLC then diverts each carton to the appropriate storage location.

-

Conveyor Jam Detection

Conveyor Jam Detection

In the event of packages or totes coming around the corner of a conveyor getting caught, a WORLD-BEAM QS18 Universal Voltage sensor positioned at a bend will communicate to an alarm or PLC that an object has become lodged in front of it, alerting employees to the presence of a jam.

-

Baggage Handling

Baggage Handling

WORLD-BEAM QS18 Universal Voltage sensors mounted along an airline conveyor detect the presence and position of passing luggage. QS18 Universal Voltage sensors can be connected to either AC or DC power, allowing them to operate in large conveyor applications already using AC power without requiring a separate power supply. The robust, compact housing and multiple mounting options add to the versatility of WORLD-BEAM QS18 Universal Voltage sensors.

-

Retrofitting for Pallet Detection

Retrofitting for Pallet Detection

Banner’s Q76E retroreflective sensor uses a wide vertical beam. The beam from a single Q76E crosses the path of the conveyor horizontally to a corresponding reflector, which delivers light back to the sensor. This provides superior detection for any leading edge that interrupts the beam, at any angle, which makes it ideal for retrofitting conveyor systems to reliably identify the presence or absence of palleted items.

-

Mail Sorting for Size

Mail Sorting for Size

Three QS18 opposed mode sensors above the roller conveyor detect any passing object, triggering the horizontal QS18 sensor. Letters pass below the horizontal QS18 undetected and are diverted to the letter conveyor. Parcels are detected and continue forward.

-

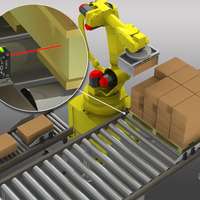

Load Station Pallet Detection

Load Station Pallet Detection

The WOLD-BEAM Q20 diffuse sensor is positioned to detect the presence of a pallet. Once the pallet is in place, an output signals the robot to begin loading.

-

Condition Monitoring on Conveyors

Condition Monitoring on Conveyors

Banner’s wireless solutions can have multiple gateways tied to respective nodes, allowing for elimination of all wires and providing flexible mounting options. The wireless structure of gateways and nodes are responsible for communicating the critical I/O throughout the facility. Even with multiple wireless products, the wireless communication system is efficient and has no cross talk interference and does not interfere with the IT department.

-

Emergency Indication on Conveyors

Emergency Indication on Conveyors

Banner’s RP-LS42 safety rope pulls line conveyors as a way to indicate emergencies and immediately shut down conveyors. If a rope pull is used during an emergency, it can be difficult to locate exactly where it was pulled. A K30 indicator light can be paired with the rope pulls in order to provide indication as to where the rope was pulled. This allows for quick and easy indication of where an emergency occurred, helping to return to normal operations as fast as possible.

-

Objects on a Conveyor

Objects on a Conveyor

The WORLD-BEAM Q20 diffuse sensors are positioned above a conveyor line in an array pattern to detect the presence of objects on a high speed conveyor.

-

Detecting Items On an AC-Powered Conveyor

Detecting Items On an AC-Powered Conveyor

WORLD-BEAM QS18 Universal Voltage sensors can be connected to either AC or DC power, allowing them to operate in large conveyor applications already using AC power without requiring a separate power supply. The robust, compact housing and multiple mounting options add to the versatility of WORLD-BEAM QS18 Universal Voltage sensors.

.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)