-

Company

-

Banner Blog

-

Smart Sensors: IO-Link for Remote Monitoring and OEE

Smart Sensors: How to Use IO-Link for Remote Monitoring and OEE

This article describes a key technology—IO-Link communication—that provides users with remote monitoring capabilities on the field device level. This article also explains how the remote data made accessible by this technology can help increase machine uptime, productivity, and throughput—all of which have an impact on a business’s bottom line.

Remote Monitoring at the Sensor Level

Data from sensors and other field devices was once difficult to access, if not completely unavailable. For many manufacturers, these devices offer untapped potential for greater visibility into their operations and more advanced, data-driven decision making.

With the rise of the Industrial Internet of Things (IIoT), device-level data can now be made accessible to operators and plant managers, providing valuable insight into machine performance, process inefficiencies, and more. Real-time remote monitoring of sensor status allows operators to address issues as they arise, and often resolve concerns before they escalate to line shutdown.

IO-Link communication is one technology that provides users with remote monitoring capabilities on the field device level.

How IO-Link Works

IO-Link (IEC61131-9) is an open standard serial communication protocol that allows for the bi-directional exchange of data from sensors and devices that support IO-Link and are connected to a master. The IO-Link master transmits data from IO-Link devices such as sensors and indicators over various networks, fieldbuses, or backplane buses. Device data is therefore accessible for immediate action or long-term analysis via a controller such as a PLC or HMI. This gives users more information about their devices and enables remote monitoring of machine performance.

The ability to monitor sensor outputs, receive real-time status alerts, and adjust settings from virtually anywhere allows users to identify and resolve problems that arise on the sensor level in a timely manner. This also means that users can make decisions based on real-time data from the machine components themselves, which can reduce costly downtime and improve overall efficiencies.

For more information about IO-Link technology, read What is IO-Link and 5 Key Advantages.

3 Ways to Use IO-Link for Remote Monitoring

1. Read and Change Device Parameters Remotely

With IO-Link, users can read and change device parameters through the control system software, enabling fast configuration and commissioning that saves time and resources. In addition, IO-Link sensors can accommodate multiple recipes that can be quickly and dynamically changed from the control system as needed—such as in the case of product changeover. For example, a line that runs products of different sizes at different times will require changes to sensors’ distance thresholds.

During changeover, the IO-Link master simply writes the new threshold to the sensors, and the sensors do not need to be present to teach. This shaves significant time off sensor configuration for changeover which reduces downtime, increases productivity and throughput, and allows machines to accommodate greater product diversity.

2. Remotely Monitor Device Health and Runtime

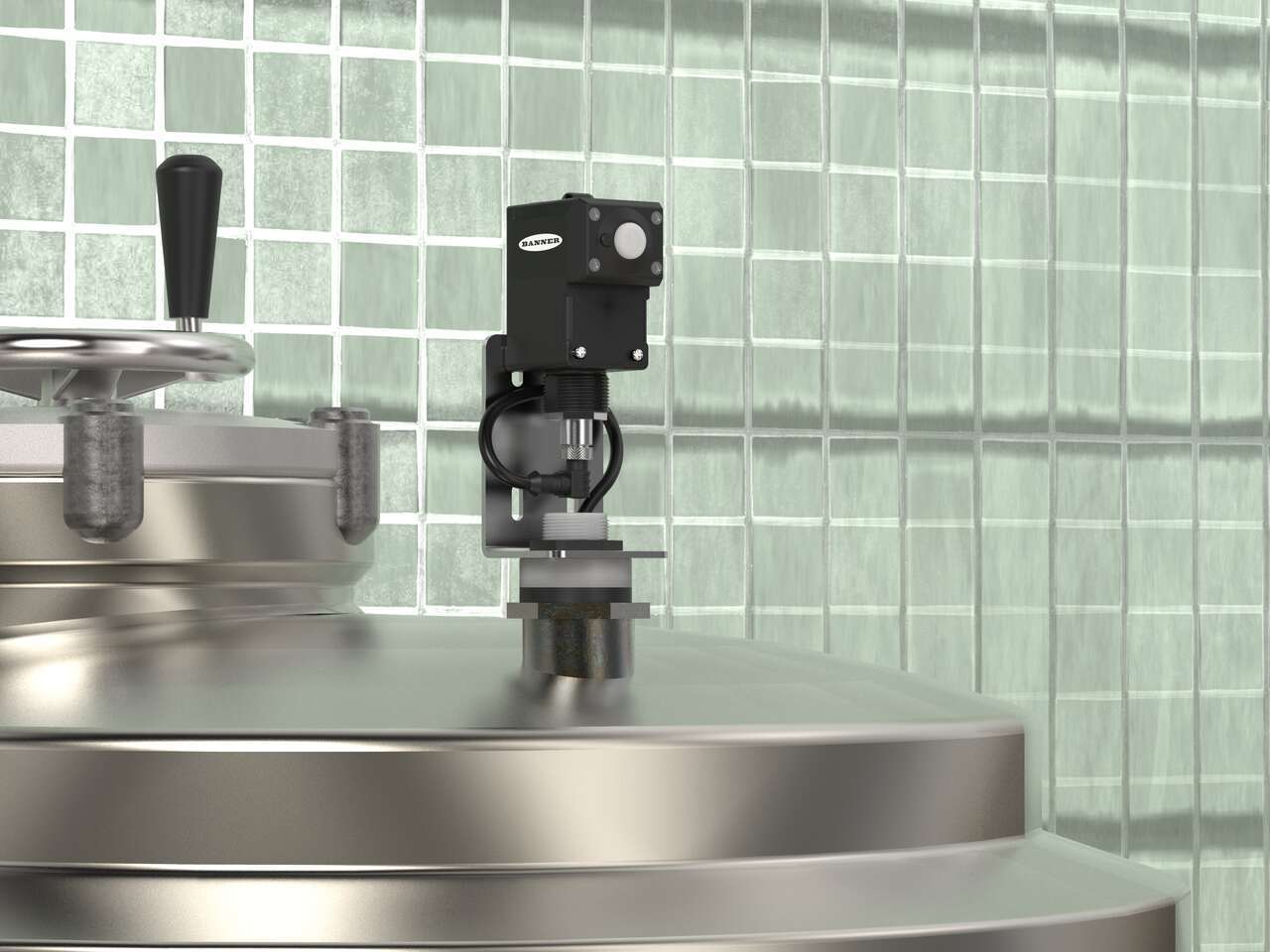

IO-Link communication also provides the ability to establish alarms and predictive maintenance tasks based on real-time sensor data. For example, sensors like the Q4X laser distance sensor with IO-Link provide excess gain data via IO-Link, which can be used to identify when a sensor requires cleaning (as dust and other particles accumulate on the sensor lens, excess gain decreases). Alerts can be set up so that sensors can be cleaned before the buildup of debris impacts its sensing function. Device connection issues are also reported in real-time, allowing them to be resolved in a timely manner.

In addition to providing valuable health outputs, IO-Link also allows users to track total runtime data to predict when to replace a device. With this information, sensors can be replaced during scheduled maintenance, avoiding unnecessary downtime. Runtime data can also be used for OEE calculations (see point 3 below).

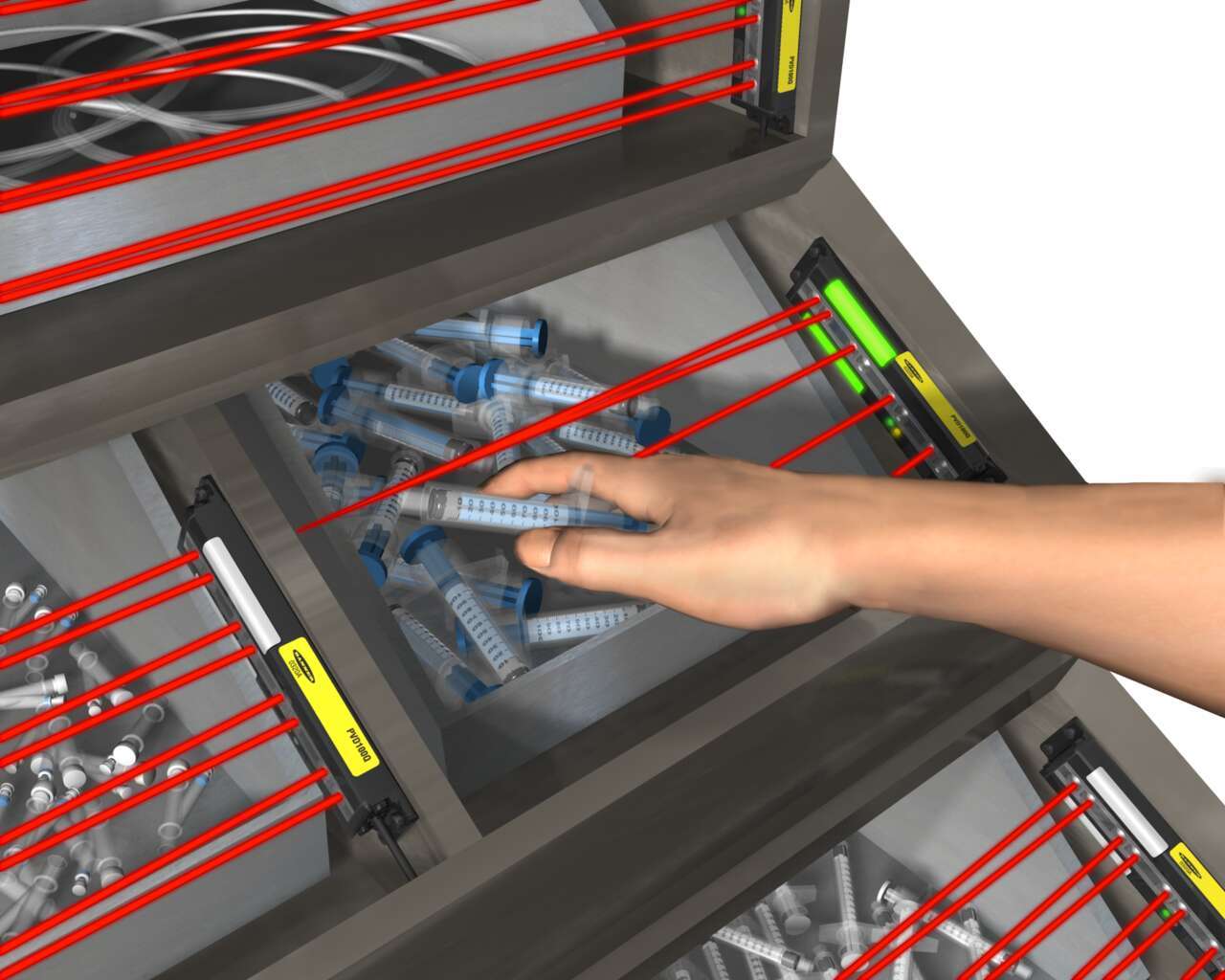

Furthermore, the discovery function with IO-Link indicates which sensor needs attention, especially where many sensors are grouped together. In the example in the image below, there are multiple Q4X sensors in a confined space, making it difficult to determine which sensor requires cleaning. The discovery function allows the problematic sensor to flash, making it easy to identify and address the issue quickly.

3. Utilize Logged Data to Maximize Overall Equipment Effectiveness (OEE)

IO-Link devices are also instrumental in providing data for OEE calculations. Overall Equipment Effectiveness (OEE) is a calculation of manufacturing process efficiency that takes into account three primary factors: availability, performance, and quality.

The availability factor considers events that decrease total runtime, including planned stops (such as for product changeover) and unplanned stops. The performance factor takes into consideration anything that decreases the speed of the manufacturing process while it is running. And the quality factor accounts for parts or products that do not meet quality standards (parts that must be scrapped or reworked, resulting in wasted time).

The OEE calculation evaluates these factors and expresses the result as a percentage value, with 100% meaning that only good parts are manufactured (quality), as quickly as possible (performance), and without any stops (availability). The results of this calculation provide actionable insights into the critical sources of waste in a manufacturing operation.

To reduce waste and improve OEE, visibility into where and when inefficiencies occur is essential, even down to the sensor level. Access to performance and runtime data from IO-Link sensors and indicators are therefore critical for calculating OEE and identifying steps to improve efficiency of your machines, processes, and people.