-

Applications

-

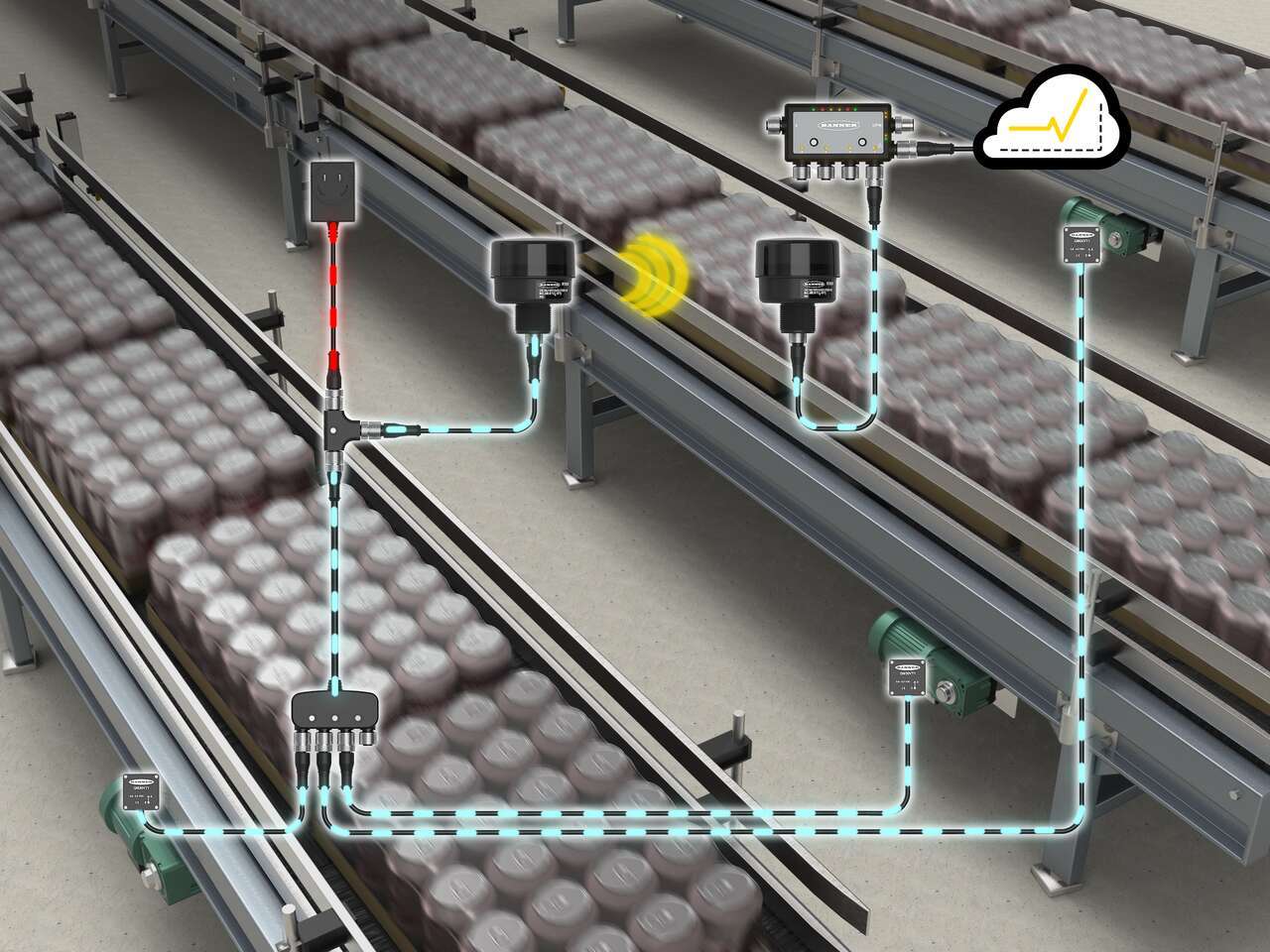

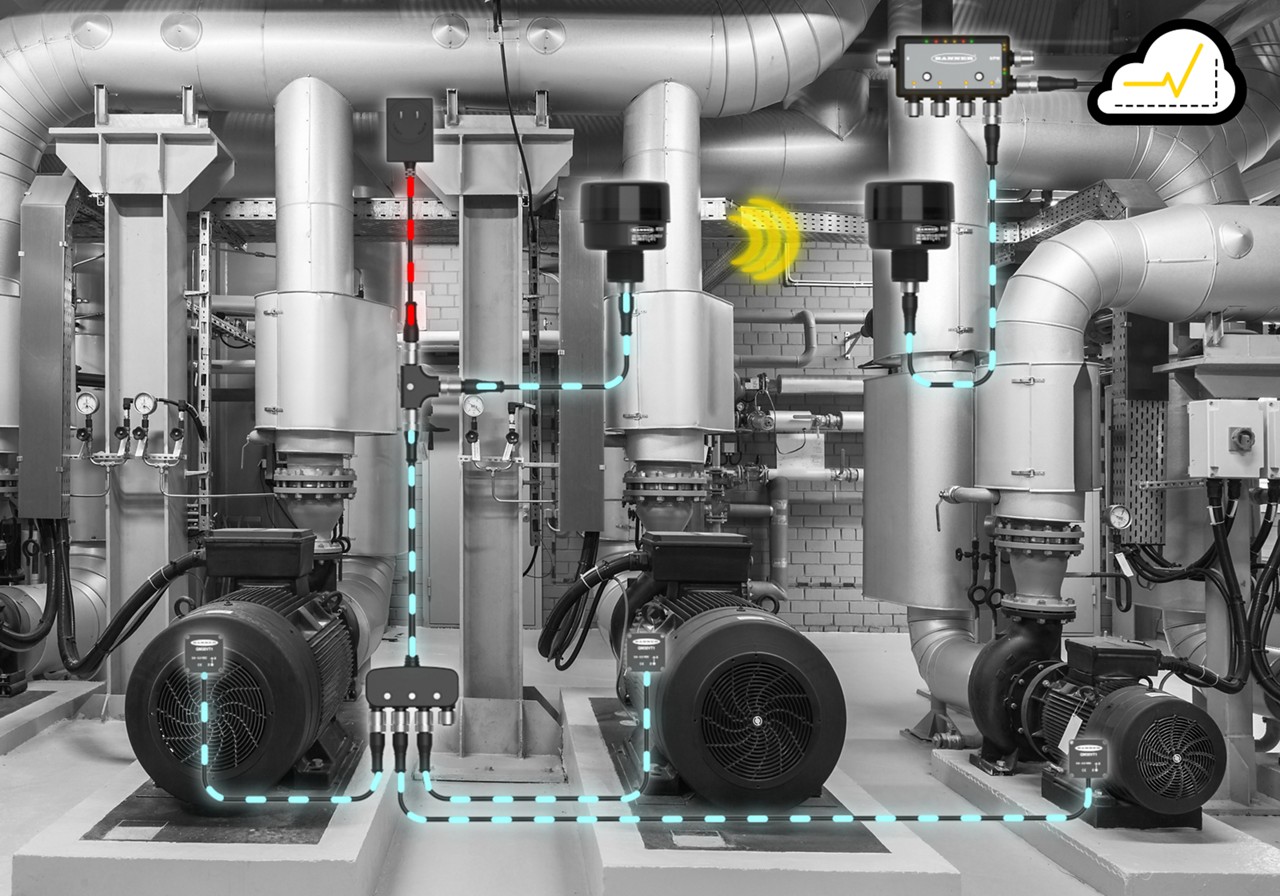

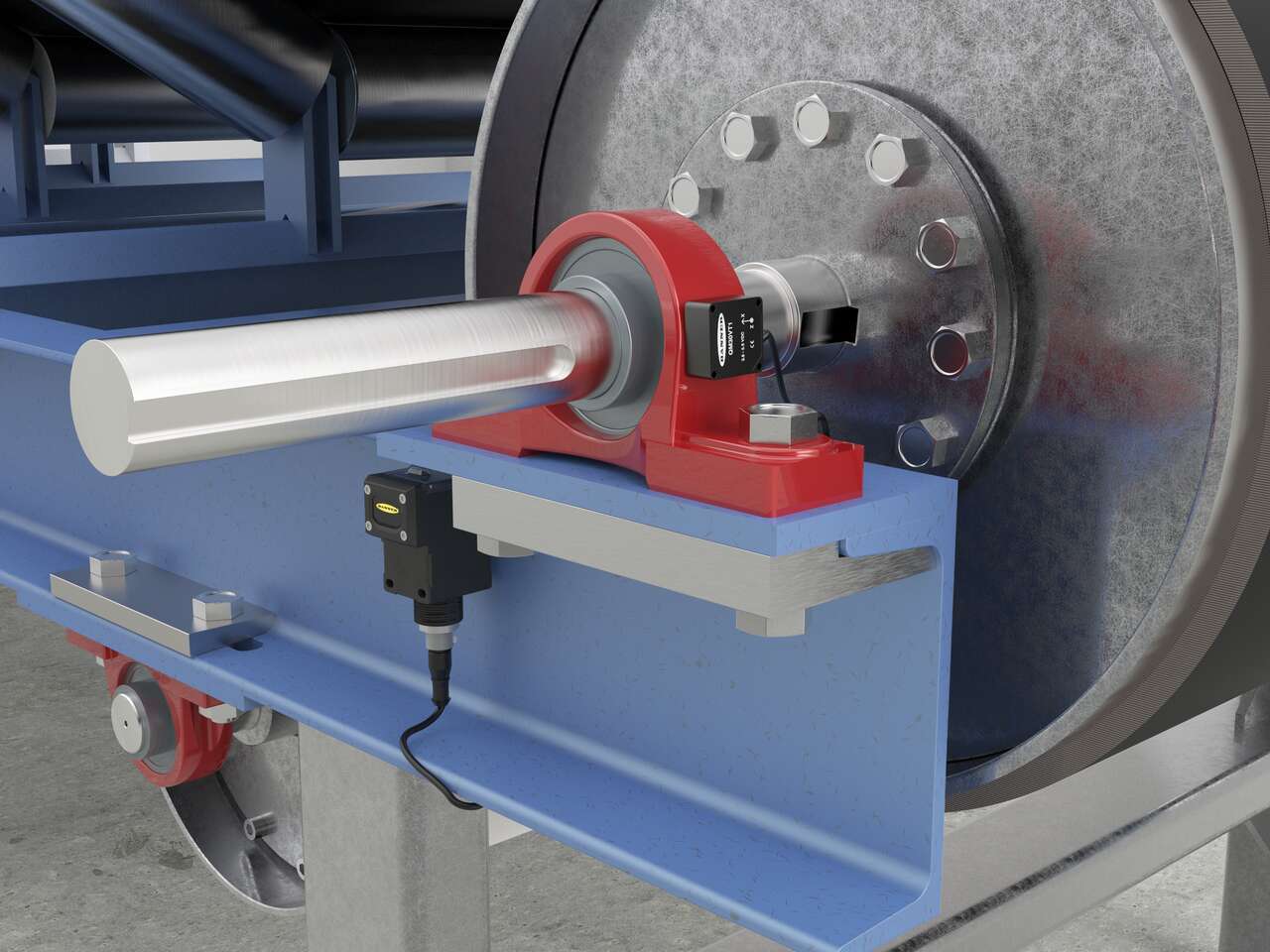

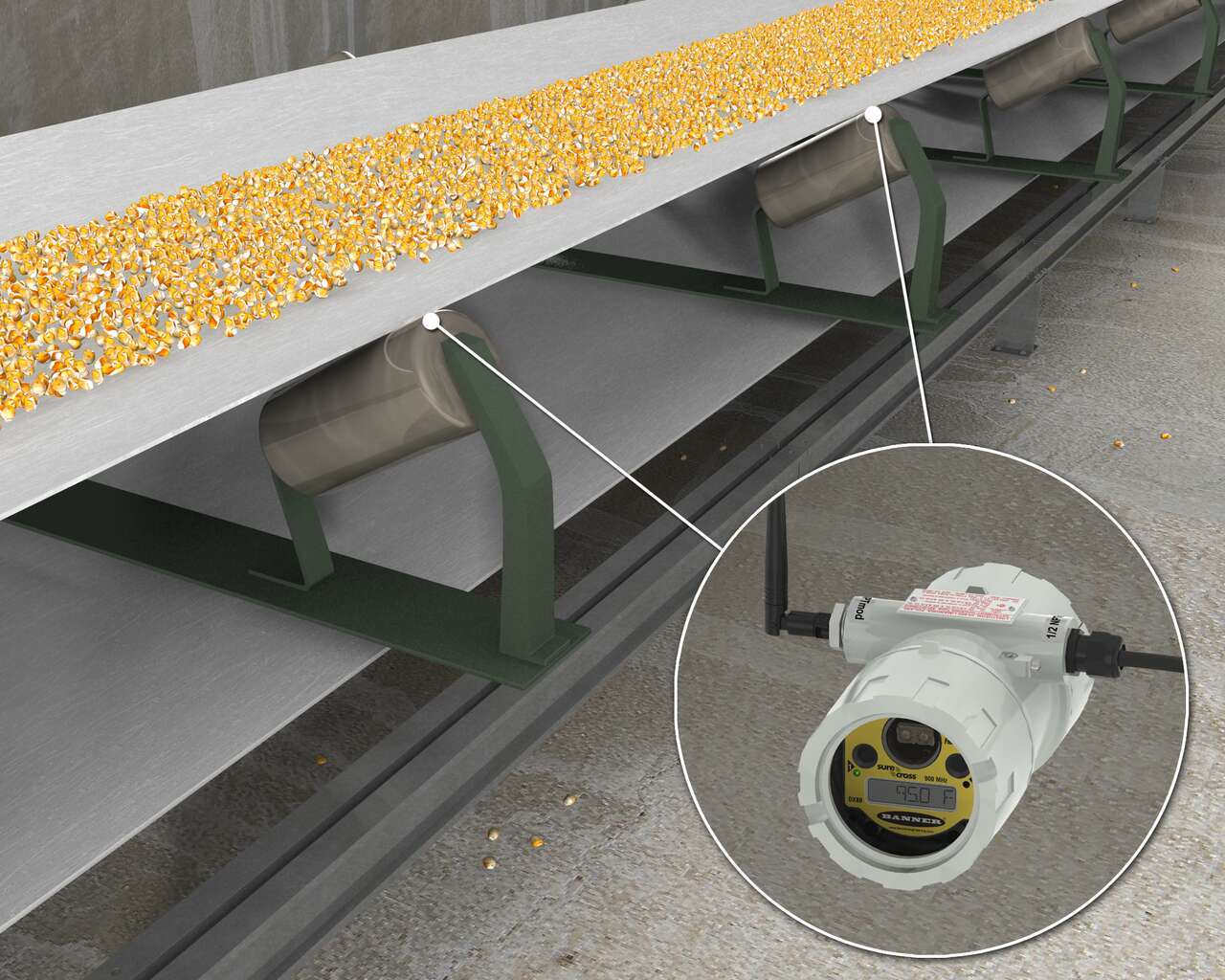

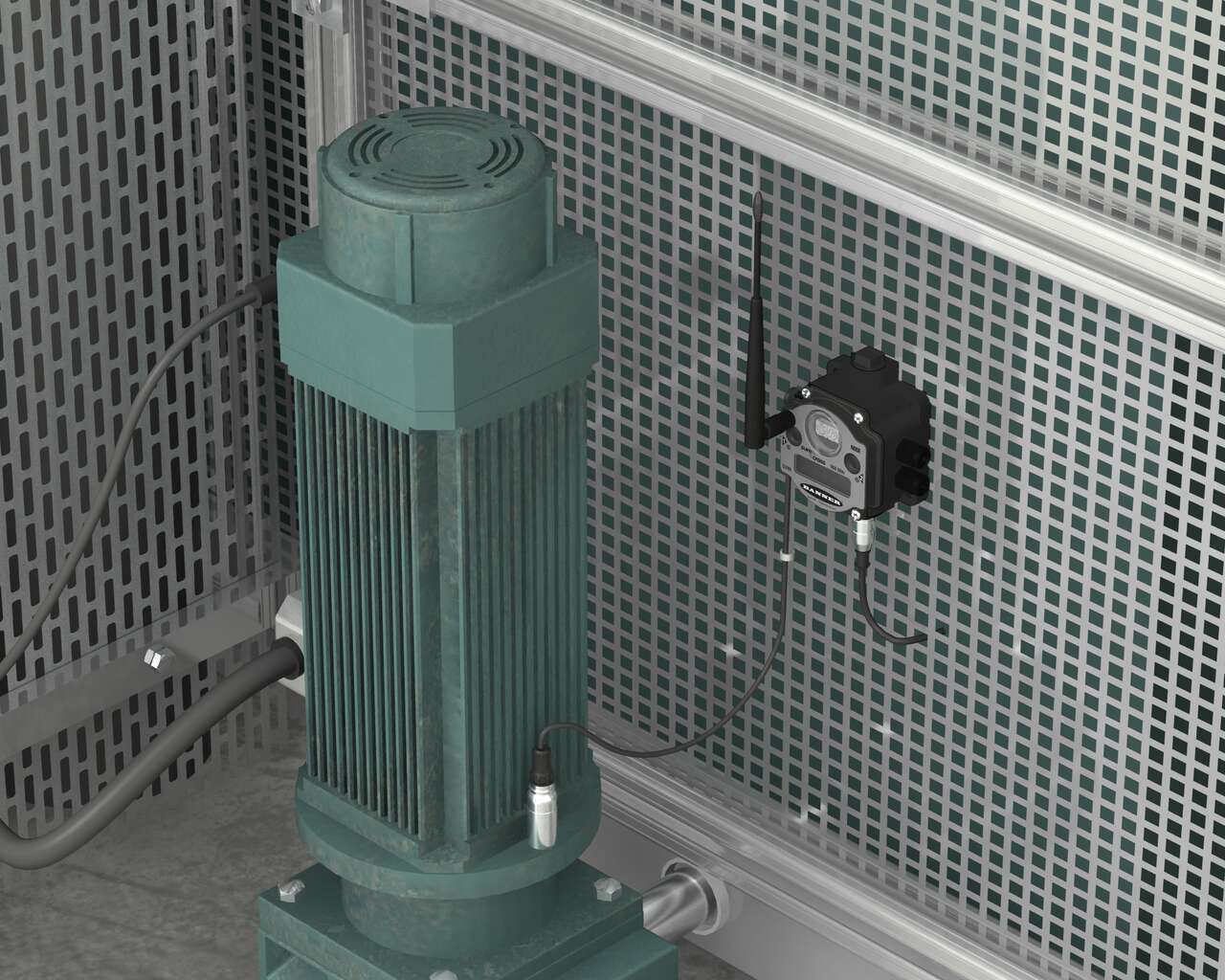

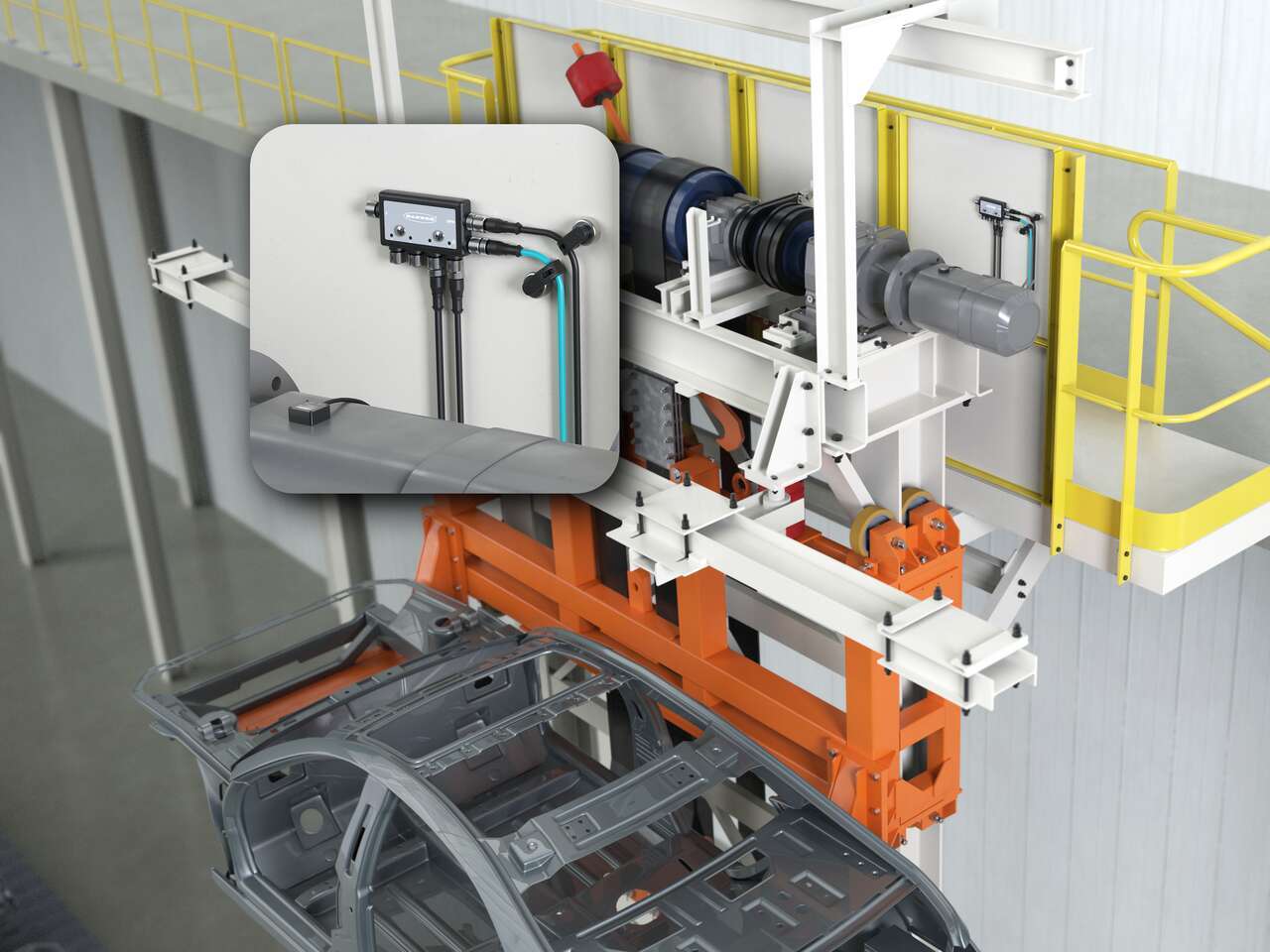

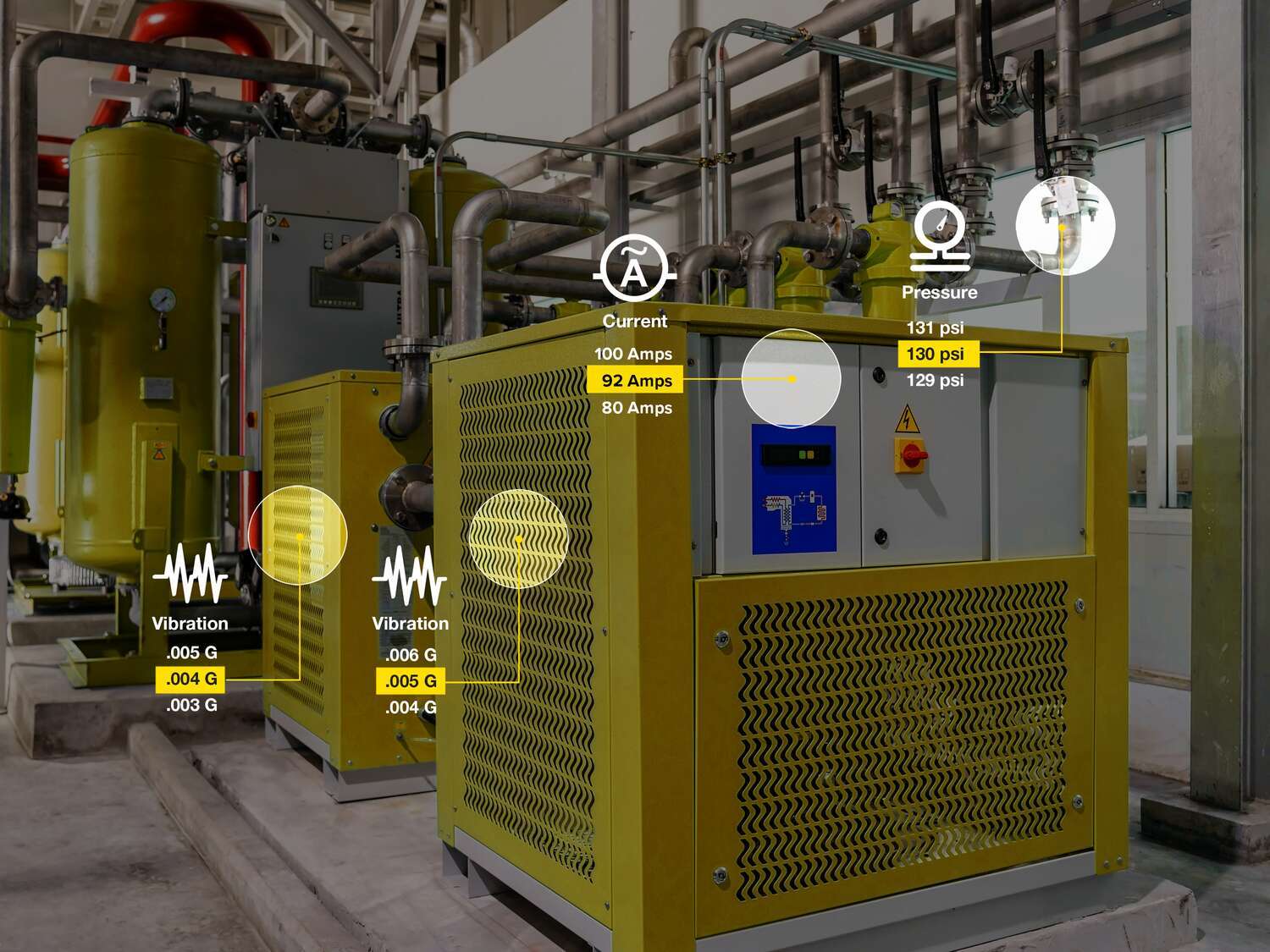

Predictive Maintenance

Predictive Maintenance

Predictive maintenance is an automated approach to monitoring and diagnosing assets, which can identify and track gradual performance decline before traditional maintenance methods can spot it. Using condition monitoring equipment, this approach leverages data, analytics, and machine learning to optimize the performance and longevity of industrial equipment.

With predictive maintenance, technicians focus on needed repairs, rather than routine checks, reducing labor costs. The data collected by a condition monitoring system lets plant managers make educated decisions rather than gut decisions about production capacity and new equipment purchases. Besides saving money by avoiding unnecessary checks and unnecessary maintenance, a predictive maintenance solution also extends the equipment’s life because maintenance is optimized. Read more about our different applications below and how condition monitoring and preventative maintenance is changing the future for predictive maintenance.