Food Traceability and Safety

Protect Public Health and Your Brand's Reputation

Product recall is costly not only in terms of lost revenue, wasted materials, and production time but also in terms of brand reputation and brand loyalty. The sooner food safety issues can be addressed and mitigated, the lower the risk of a large-scale recall.

When food safety recalls do occur, it is critical for companies to be able to remove all spoiled or contaminated products from the market as quickly as possible to limit the impact on public health.

Identification solutions for food traceability not only facilitate faster recalls when they occur, but can help prevent recalls by verifying products at every step.

Traceability in food and beverage industries is more important than ever before, which is primarily driven by growing consumer demand for visibility into the origins of their food. Also, allergies and sensitivities to specific ingredients, such as those containing gluten, necessitate proper labeling of packaged food products.

However, as traceability has become even more critical, it has also become much more complicated due to the highly matrixed and global nature of food and beverage supply chains.

A reliable identification application is a foundation for track and trace solutions to ensure that food is safe for consumption and that the source of the ingredients are validated for health- and environmentally-conscious consumers.

Explore the identification solutions below, or contact us to discuss your specific application.

Isolate Food Safety Issues with Detailed Tracking

- In food packaging, barcodes are embedded with information specific to each product and production run to identify products throughout the supply chain.

- As part of a track and trace program, a packing house verifies product barcodes at multiple points during packaging, creating a record that will allow the company to quickly identify and isolate any product with quality issues in the event of a recall.

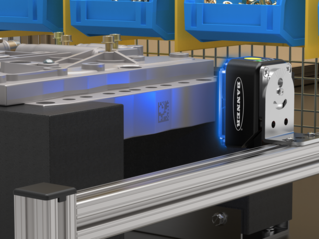

- Imager-based barcode readers, like the ABR 3000 from Banner, are capable of decoding the broadest range of 1D and 2D barcodes. Deployed along the packaging line, the ABR 3000 verifies that the barcode printed on each package is present, readable, and correct for each production run.

- The information contained in the barcodes is sent via an Ethernet connection to the company’s production management system which records the data for future reference.

Prevent Recall Due to Undisclosed Allergens

- Food allergies are potentially lethal to the consumer, so it is essential that food packaging accurately discloses the allergens present in the food item. By law, eight major foods must be disclosed on packaging: milk, eggs, fish, shellfish, tree nuts, peanuts, wheat, and soy.

- However, one error that can occur during the processing of packaged foods is when a product is placed in the incorrect packaging, resulting in inaccurate labeling of food contents.

- To prevent mislabeled product and ensure quality and food safety, the iVu barcode reader can determine whether the label pattern matches a reference pattern taught to the device.

- Automating label inspections with a reliable vision solution improves quality control by reducing the risk of error common to manual inspections, which in turn helps reduce the incidence of a product recall due to undisclosed allergens.

Choose Rugged, Water-Resistant Devices

- In food and beverage applications, identification devices like barcode readers are often near water, and other liquids used to keep surfaces clean and free from debris or other contaminants that can compromise food safety.

- In most cases, identification devices are unlikely to experience direct, high-pressure, high-temperature washdown.

- However, water may still come in contact with the devices, so water-resistance is essential to ensure that barcode scanners perform reliably and are not damaged.

- Depending on the application, an IP65 or IP67 rated housing ensures that the device will function reliably even when exposed to water.

Imager-Based 1D and 2D Barcode Reader

Les lecteurs de code-barres de la série iVu BCR combinent de puissantes fonctionnalités de décodage et une grande facilité d'utilisation pour résoudre les applications de traçabilité. Ces lecteurs de codes-barres polyvalents se déclinent en différents modèles proposant un large choix de lentilles, d'éclairages et d'interfaces utilisateurs.

- Lecture d'un large éventail de codes-barres 1D et 2D, y compris les codes endommagés, déformés et autres codes difficiles à lire

- Lecture possible de plusieurs codes à barres dans n'importe quel sens au cours d'une seule inspection

- Configuration, gestion et surveillance des inspections à l'aide d'un écran tactile intégré, d'un écran tactile déporté ou d'une interface PC

- Protocoles de communication Ethernet et série pour simplifier l'intégration des dispositifs et la collecte de données IIoT

- Boîtier robuste, certifié IP67, idéal pour les espaces restreints et les environnements industriels

- Large choix d'options d'éclairage intégrées pour simplifier l'installation et optimiser le contraste

- Lentilles interchangeables, y compris une large gamme d'options standard et avec monture en C pour répondre aux besoins de n'importe quelle application

TCNM Series

Laser-Based 1D Barcode Scanner

Capable de décoder une douzaine de codes-barres linéaires usuels, le TCNM fournit une lecture rapide, une grande profondeur de champ et une haute résolution.

- Le lecteur de codes à barres peut décoder plus d'une dizaine de codes à barres linéaires

- 500 à 1000 lectures par seconde

- Configuration et diagnostique par l'utilisation du bouton "SMART-TEACH" et des indicateurs à LED

- Code de restauration d'algorithme pour la reconstructions des informations d'un code endommagé

- Le logiciel GeniusPlus et un protocole de communication interne permettent d'éliminer l'utilisation d'un multiplexeur externe lors d'une configuration multiple

- Boîtier IP65 robuste