Safely Start and Stop Machines

Safety and Indication for Machine Start/Stop

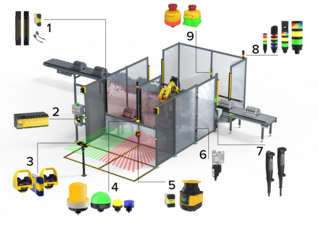

Operators must be able to safely start machine processes as well as safely stop them in an emergency using a variety of safety-rated devices including emergency stop buttons, rope pulls, and two hand control devices.

Banner Engineering combines ergonomic safety-rated devices with LED indication for a more intuitive user experience and at-a-glance visual management of your safety systems. Keep reading to learn about the different types of safe operator interfaces.

Emergency stop buttons (or e-stops) and rope pulls ensure safe stops in emergencies. E-stops are mechanical buttons that must be pressed with force to actuate. Pressing an e-stop, or pulling the rope on a rope pull, will immediately stop hazardous motion of the machine.

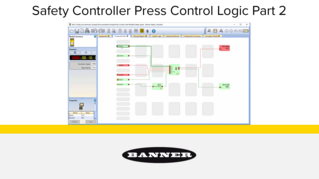

Two hand controls are devices that initiate machine processes, for example when operating a mechanical power press. The operator must have one hand on each control before the machine will safely start, and the machine will continue operation only as long as both hand controls are actuated. This ensures that the operator's hands are away from the point of operation during the entire time the machine is moving.

Please note: The information on this page is meant for educational purposes only and is accurate as of the time of publication. Always consult a safety expert about your specific application before implementing any machine safety measures.

Illuminated Base Quickly Identifies Pressed Button

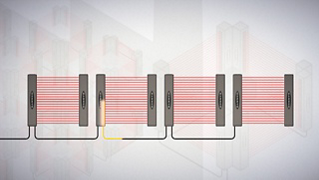

With traditional e-stops, it can be time-consuming to determine exactly which button was pressed, and typically an emergency stop condition requires a reset of all e-stop buttons on a line. To solve this challenge, illuminated e-stops have an LED base that can be configured to change from yellow to flashing red when pushed. The colored lights n the e-stop base provide easy visual indication of armed button, pushed button, or system status.

This makes it easy to quickly see the status of all estops at a glance and instantly identify an actuated button. The faster the response to the stop condition, the more quickly the machine can be restarted, reducing unplanned downtime. lluminated e-stops can also reduce commissioning time and costs due to the ability to series connect the e-stops to a safety controller. This not only reduces cable costs and wiring time, but also reduces the number of inputs used at the safety controller.

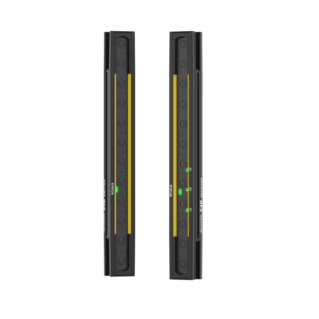

Quickly Identify Pull Rope with LED Indicator

Rope pull switches run along the length of a conveyor so the operator can grab and pull it from anywhere to immediately stop the conveyor. When the rope is pulled, it can often be difficult to locate the safety device in need of reset. To help the operation to return to normal quickly, a LED domed indicator can be mounted to the housing of rope pull switches for fast identification of the unit that was activated.

Spans of rope range from 6 m to 100 m, providing the flexibility to safeguard long or short conveyors. Rope pull switches from Banner are also made with heavy-duty thermoplastic housing for use in demanding industrial settings.

Start, Stop, and Indication Functions in One Ergonomic Solution

A run bar combines two hand control devices, e-stops, and indicators into a convenient ergonomic solution for operating machinery. The two-hand control system makes the operator a “hostage” while the hazard is present, preventing the operator from putting their hands in the way of the hazard.

Two hand control actuators must be located in a way that hazardous motion is completed or stopped before the operator can release one or both of the buttons and reach the hazard.

Ergonomic Design, Intuitive Visual Management

Une base de montage de 30 mm permet d'installer et de raccorder facilement le système, sans aucun assemblage, câblage individuel ou boîtier supplémentaire requis.

- Diminution du coût de la main-d'œuvre grâce à un bouton d'arrêt d'urgence intégré, prêt à être installé

- Possibilité de câblage en série de plusieurs boutons avec logique intégrée signalant le bouton enfoncé de façon visible

- Conception du verrouillage conforme à la norme ISO 13850 et manœuvre positive d'ouverture (directe) conforme à la norme CEI 60947-5-1

- Conception robuste de classe IP65

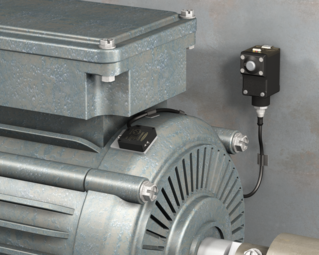

Emergency Stop for Conveyors & Large Machines

Les interrupteurs d'arrêt d'urgence utilisés conjointement avec un câble en acier offrent un dispositif d'actionnement d'arrêt d'urgence pour les convoyeurs et les grosses machines.

- Portées entre 6 et 100 m

- Modèles avec réarmement manuel ou automatique disponibles

- Durée de vie minimale de l’interrupteur équivalant à 1 million d’opérations

- Boîtiers robustes supportant les environnements difficiles

- Le commutateur est activé quand on tire sur la corde, si elle se détend ou se casse.

- Conception conforme aux exigences d’ouverture positive pour les interrupteurs à câble

An Ergonomic Solution for Machine Start/Stop

Solution ergonomique robuste pour la protection et l'actionnement de la commande bimanuelle lorsqu'elle est connectée aux modules de commande bimanuelle DUO-TOUCH SG.

- Solution économique et pratique pour l'actionnement de la commande bimanuelle lorsqu'elle est connectée aux modules de commande bimanuelle DUO-TOUCH SG ou à d'autres systèmes de commande comparables

- Conception ergonomique pour réduire les tensions sur le poignet, la main et les bras

- Modèle avec bouton d'arrêt d'urgence

- LED d'indication de mise sous tension, de sortie et d'erreur très visibles sur les boutons STB

- Conforme aux normes ANSI B11.19 et ISO 13851 (EN574)

![Vibration Monitoring a Main Air Handler [Success Story]](/content/dam/banner-engineering/3d-renders/application-notes/predictive-maint/qm30vt-motor-vibration-detection.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Maintenance prédictive des pièces rotatives d'un convoyeur [Exemple de réussite]](/content/dam/banner-engineering/photography/general---stock-photography/stock_photo_new/AdobeStock_111970609.jpeg/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Mesure de température pour une application d'assainissement thermique [Exemple de réussite]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2013/SURE-CROSS-Flex-Power-w-RTD---Temp-Measure-in-Flour-Mill.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Détection de différents repères [Exemple de réussite]](/content/dam/banner-engineering/photography/general---stock-photography/valueprop/edited/wcc-migration/2015/R58_roll_closeup.jpg/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Simplification de la gestion de dispositifs de sécurité [Exemple de réussite]](/content/dam/banner-engineering/photography/general---stock-photography/valueprop/edited/wcc-migration/2015/Algus_MKuhlow.jpg/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Des barres d'éclairage à LED plus puissantes qui réduisent les délais et les coûts de construction des machines [Exemple de réussite]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/WLB32%20Muti-Station%20Test%20Workstation%20Illumination%20(High_Res_PSD).psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Installation rapide d'une solution d'éclairage durable à LED pour la mise en lumière des postes d'inspection de bandes [Exemple de réussite]](/content/dam/banner-engineering/photography/success-story-photography/WLB32-LED-Lights-Web-Inspection.jpg/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Indication d'état sur les véhicules sans conducteur [Exemple de réussite]](/content/dam/banner-engineering/photography/general---stock-photography/stock_photo_new/AdobeStock_189577689.jpeg/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Mesure précise des ingrédients de boulangerie [Exemple de réussite]](/content/dam/banner-engineering/photography/general---stock-photography/valueprop/edited/wcc-migration/2015/dropbox3.jpg/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Contrôle de petits connecteurs [Exemple de réussite]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2014/LE550-Vehicle-Seat-Weight-Sensor-Connector.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Zéro défaut sur un bobinoir industriel [Exemple de réussite]](/content/dam/banner-engineering/photography/general---stock-photography/valueprop/edited/wcc-migration/2015/Fotolia_51604759_M.jpg/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Éclairage à LED utilisé pour contrôler les produits pharmaceutiques liquides [Exemple de réussite]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2011/WLA-IV-Bag-Manual-Inspection---Particulates.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Présence de tubes de retour d'air sur une remplisseuse [Exemple de réussite]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2013/iVu-C-Mount-Remote-washer-Tube-Inspection.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Mesure de la durée avant départ pendant les interventions [Exemple de réussite]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2014/R-GAGE-Vehicle-Detection---Firehouse.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Washdown Cover for Emergency Stop Buttons [Video]](/content/dam/banner-engineering/projects/video-thumbnails/E-Stop_Cover_Video_Thumbnail-new.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)