Delivering Pinpoint Diagnostic Information to Robotic Sortation Systems

Challenge

The controls engineering team at a company specializing in robotic sortation systems was faced with a design challenge for a new machine. They aimed to minimize unplanned downtime for their end-user by making it easier to identify which safety device triggered an emergency shutdown. The new machine would require 27 safety devices, comprising 15 e-stops and 12 door switches. The existing solution required hardwiring each safety device to the back of the control panel and connecting each device to a dedicated input on the safety controller. Each of the 27 devices also required a second dedicated input on the safety controller for monitoring. That’s 54 required safety controller inputs, which means a controller, multiple expansion I/O cards in the panel, and excessive cabling along the machine would be required. The extensive amount of cabling required for this approach would complicate the installation, significantly increase the cost of the system, and make diagnosing wiring issues especially challenging.

Solution

After visiting the controls engineering team and gaining a thorough understanding of the challenge, Banner recommended a solution using their safety products featuring In-Series Diagnostics (ISD), which would reduce downtime, simplify installation, and control costs. ISD is a technology developed by Banner that allows safety devices to communicate on a network while maintaining the highest safety ratings. With the use of Banner E-Stops and SI-RF Door Switches with ISD, the team was able to go from 54 inputs to just two. Those two inputs carry the redundant stop signal coming from any device and provide the network interface for the ISD signals. Each device on the ISD network establishes its own unique ID, enabling the safety controller to pinpoint the exact device and diagnostic signal it sends, such as “button pressed,” “door open,” or other diagnostics like “voltage” and “door ajar.” The team also took advantage of ISD devices’ ability to be installed in series (i.e., daisy chain) eliminating excessive cabling by routing a single 4-wire M12 cable along the machine. Between the Banner SC10 Series Safety Controller and XS26 Series Expandable Safety Controller, the engineering team chose the SC10 for its built-in safety relays, compact size, Ethernet interface, and on-board I/O. The SC10 is also a very cost-efficient controller, and when combined with ISD, it can monitor up to 64 safety devices, further enhancing its value.

Before the team received their hardware, they used the drag-and-drop function block interface and simulation mode in Banner’s free and easy-to-use Machine Safety Software to design and simulate their application. After the hardware arrived, they used the same free software to quickly program the SC10, simplifying setup and avoiding the need for costly software licenses. They chose to use the EtherNet/IP interface on the SC10 safety controller to gather diagnostic information that would be displayed on the machine’s HMI, and with the status of each e-stop and door switch being available in the EtherNet/IP register map, they were able to present a specific warning on the HMI, notifying machine operators or maintenance staff which specific safety device was preventing the machine from operating.

The Banner safety solution, composed of e-stops and door switches with ISD, along with the SC10 hybrid safety controller, delivered the advanced diagnostics the engineering team needed to provide their end-user with faster issue resolution and higher levels of uptime. At the same time, the solution reduced wiring requirements, controlling costs and simplifying installation complexity.

Featured Products

-

In-Series Diagnostics

In-Series Diagnostics (ISD) makes it easy to troubleshoot machine safety systems, prevent faults from occurring, and reduce downtime.

-

SI-RF RFID Safety Switches

SI-RF Series safety switches utilize RFID technology to monitor doors, gates, and other mechanical safeguards. They will send a signal to the machine control system to prevent or stop hazardous situations when the guard is not in the proper position.

-

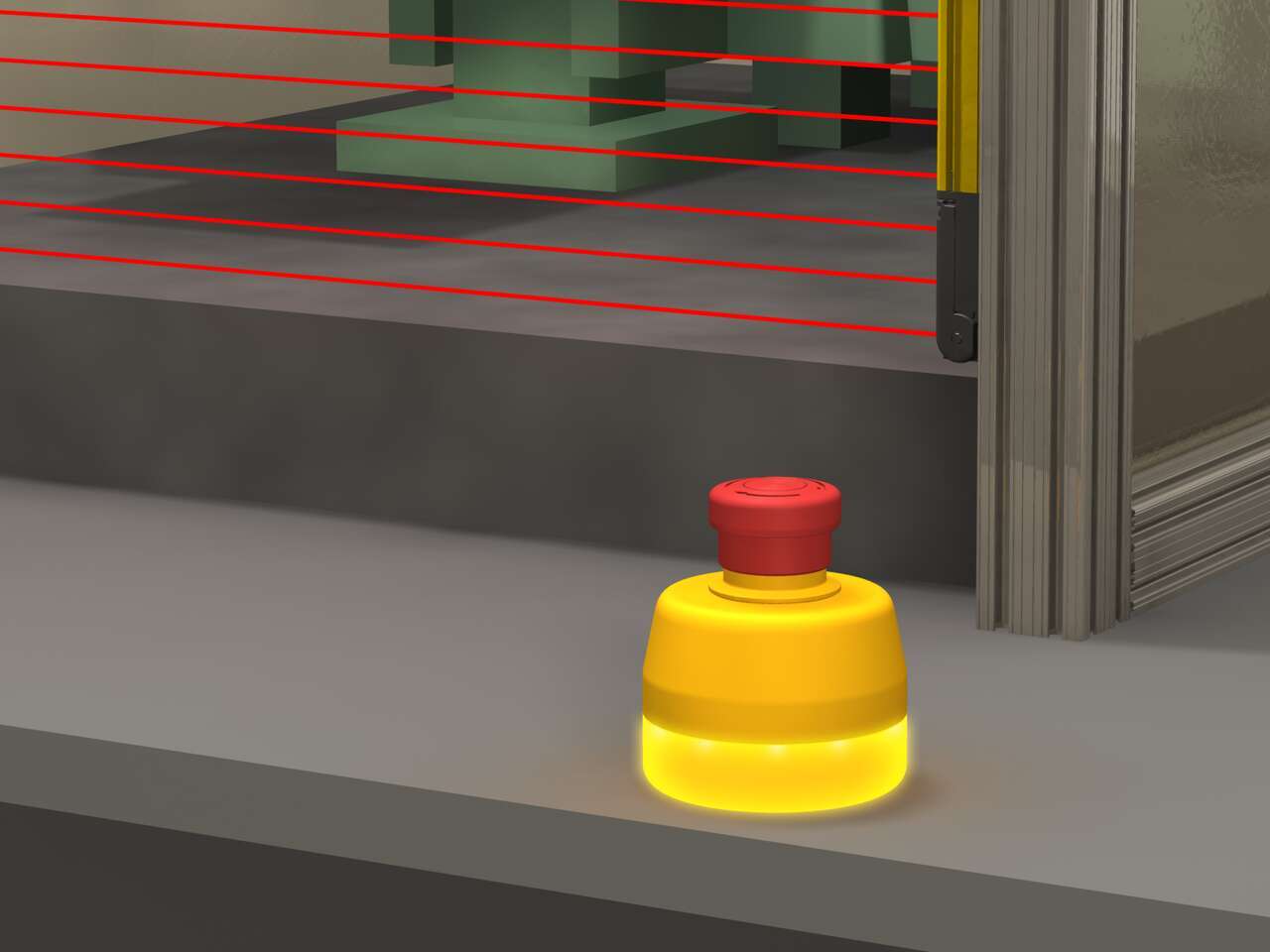

Commandes d'arrêt et d'arrêt d'urgence

Les dispositifs d'arrêt d'urgence, ou les arrêts d’urgence, offrent au personnel un moyen d'arrêter un système ou une machine en appuyant sur un bouton ou en actionnant un câble afin d'éviter tout dommage matériel et corporel.

-

SC10 Series Safety Controller / Relay Hybrid

Replaces the functionality of two safety relay modules with one compact, cost-effective device. Supports up to 10 inputs, 4 convertible inputs, and 2 dual channel 6 Amp relay outputs.

-

Contrôleur de sécurité avec modules d'extension série XS26

Solution extensible idéale pour les applications de sécurité complexes utilisant généralement 3 relais de sécurité ou plus. Prend en charge jusqu'à 154 entrées sécurisées et jusqu'à 68 sorties sécurisées de 0,5 ampère ou 6 ampères chacune en utilisant des modules d'extension.