LS Series Tubular Enclosure

Heavy-Duty Type 4 Safety Light Curtains

EZ-SCREEN® LS tubular enclosure light curtains are intuitive, easy-to-use safety devices used for machine safeguarding. They are built to withstand harsh environments typically found in food, beverage and pharmaceutical manufacturing.

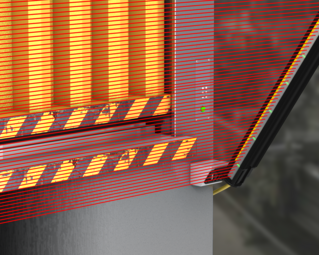

- IP69 rated hygienic tubular enclosure with hydrophobic vents to prevent condensation

- Hygienic stainless steel brackets with food grade gaskets available

- Highly visible alignment and diagnostic indicators

- 23 mm resolution (detection capability)

- Available in 7 defined heights from 280 to 1050 mm

- External device monitoring, auxiliary fault options and scan code select included

- Remote fixed blanking to ignore stationary objects available

Downloads

Technical Literature

Brochures & Catalogs

Frequently Asked Questions

Please note the following information is for educational purposes only and is accurate as of the time of publication. For any safety application, discuss your specific requirements with a safety expert.![]()

Question: Does the EZ-Screen LS safety light screen require a controller?

Answer: The EZ-Screen LS safety light screen does not require an external controller. All of the safety reliable components to make the light screen function are integrated into the housing of the emitter and receiver.

Question: Which module do you use?

Answer: Although an external controller is not required, the EZ-Screen LS is commonly used with one of three types of machine controls: a safety interface module, a safety controller, or a safety PLC.

A safety interface module is generally a dual-redundant relay to provide an output to the machine that can switch a higher load. The most common safety interface modules for the EZ-Screen LS are the IM-T-9A for DC voltage supply or the EZAC-R9A-QE8 for AC voltage supply.

A safety controller controls one or more pairs of EZ-Screen LS and many other safety components commonly found on machines, like gate interlock switches, emergency stop buttons, and two-hand control buttons, to name a few. A safety controller like the XS26-2 also contains advanced logic that often eliminates the need for a safety PLC. If relay outputs are required, an expandable relay module for the XS26-2 can be used, like the XS1RO, or an IM-T-9A interface module can be paired with any safety controller.

A safety PLC (programmable logic controller) may be required if the logic involved in the project is far too complex for a safety controller. The costs associated with safety PLCs are the highest of these options.

Question: How do you make the outputs latch and wait for an input from a manual reset button?

Answer: If the application requires the safety outputs to latch and wait for a manual reset, like when guarding the perimeter of a hazardous area, consider using a safety controller like the XS26-2 or SC26-2, or a smart universal safety interface module like the UM-FA-9A.

Question: How do you mute the light curtain?

Answer: If the application requires the light screen's output to be muted, consider using a safety controller like the XS26-2, SC26-2, or a muting safety interface module like the MMD-TA-11B.

Question: When would you use the 5-pin connectors over the 8-pin connectors?

Answer: To ensure the highest safety reliability, you have the option to use an EZ-Screen LS with 5-pin connectors when connecting to a module or safety controller that has on-board External Device Monitoring (EDM), like a safety controller or the smart UM-FA-9A module.

If you prefer to have the EZ-Screen LS monitor your downstream external controls, use the models with 8-pin connectors. You would also want the 8-pin connectors if you need to monitor the Fault Output or if the light screen pair may cross-talk with other light screen pairs and you need to use an alternative scan code.

Question: Which brackets do the LS light screens ship with? What other options are available?

Answer: Each sensor ships with two EZLSA-MBK-11 end-mount brackets. Emitters and receivers that are 980 mm and longer also include one EZLSA-MBK-12 center-mount bracket. The supplied end-mount brackets allow ±23° rotation, can be mounted with flange out or flange in, and in 90° increments. EZLSA-MBK-12 center-mount brackets allow 30° rotation in one direction and 15° in the other. Center- and side-mount brackets allow for mounting with no blind zones.

The supplied EZLSA-MBK-12 or optional EZLSA-MBK-16 side-mount bracket must be used with longer sensors if they are subject to shock or vibration. In such situations, the sensors are designed to be mounted with up to 910 mm unsupported distance (between brackets). When ordering additional brackets for vibration, remember that sensors 980 mm and longer are supplied with one EZLSA-MBK-12 center-mount bracket.

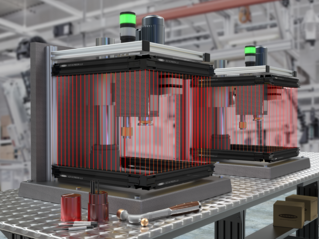

Question: How many EZ-Screen LS pairs can you cascade? Can I connect non-cascade pairs to cascade pairs?

Answer: Cascadeable models can be used as stand-alone light screens or can be cascaded up to four pairs in one system. The cascaded sensor pairs can be any length, any number of beams, or have different resolutions (14 mm, 23 mm, and 40 mm), as long as each emitter matches its receiver.

A non-cascadeable pair can be used at the end of the cascaded light curtains. A cascadeable receiver is required to use a EZLSA-K30LGR light.

Question: What resolution do you need? How far away do the beams need to be from the safety hazard?

Answer: The tighter resolution light screens are made to detect smaller objects. In general, the 14 mm resolution screens detect fingers and larger, the 23 mm resolution screens detect hands and larger, and the 40 mm resolution screens detect wrists and larger. Larger resolution light screens need to be placed farther away from the safety hazard than smaller resolution light screens to account for the additional distance a person’s finger can possibly slip through the beams without being detected.

The calculation for the minimum safety distance based on resolution and machine response time is in section 3.1.1 of the EZ-Screen LS User Manual. The beams must be at least 100 mm (4 inches) away from the safety hazard regardless of the calculated value. You should discuss your specific application with a safety expert.

Question: When would I use one or more mirrors?

Answer: Mirrors would be used most commonly in a perimeter guarding situation when protecting multiple sides of a machine. They are generally placed at the corners of a machine.

Question: Which mirrors should I use?

Answer: We have two options for mirrors: the MSM series and the SSM series. The SSM mirrors are larger and so, therefore, may be easier to align. There is a reduction of range of approximately 8% per mirror and is detailed in this chart. The use of a laser alignment tool is advised when using mirrors at longer distances. Discuss your specific application with an expert.

Question: Can the EZ-Screen LS do fixed blanking?

Answer: Yes, as long as you use a cascadable model.

Question: I see that the EZ-Screen LS light screens are certified to Type 4, Category 4 PLe, and SIL3. How do I know what safety rating I need for my application to comply with OSHA/ANSI requirements?

Answer: For any safety application, a risk assessment is essential to help you determine what safety devices are needed for compliance with safety standards. Learn more about risk assessments.

Application Notes

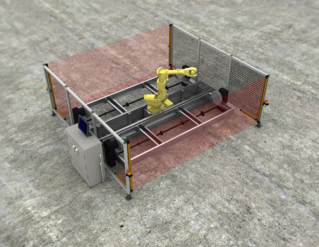

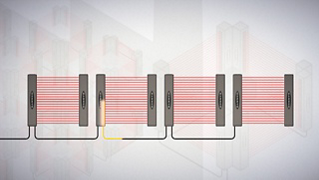

Dual-operator Robotic Work Station

See how Banner’s EZ-SCREEN LS Heavy-Duty Type 4 Safety Light Curtains uses cascading to maximize safety while minimizing cabling and equipment footprints.

Safeguarding of a Power Press

Banner Engineering’s EZ-SCREEN LS is extremely robust with heavy duty extruded aluminum IP65/67 rated housing, metal endcaps and a recessed window to protect it from collisions related to stock removal and incidental impact.

Small Assembly Station Protection with Light Curtains

EZ-SCREEN LS safety light curtains have no DIP switches, feature end-to-end sensing, and can be easily installed with automatic configuration. The use of side mount brackets creates a quick and simple installation with adjustments made from the front side of the EZ-SCREEN LS arrays, saving time during setup. Maximizing machine uptime and reducing repair and replacement expenses helps companies remain competitive.

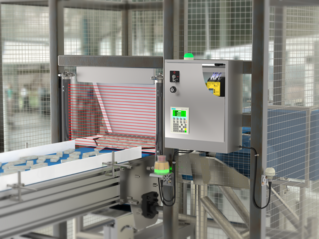

Safeguarding Access Points to a Depalletizer

An LS Series safety light curtain with a mute arm kit in T-configuration combined with an XS26 Series safety controller is an easy-to-implement solution that protects staff from potential hazards without disrupting the flow of pallets to the depalletizer.

Safety Measures for Meat Slicing Machine in Harsh Conditions

Safety light screens on a meat slicer protect operators from sharp blades while in operation. The environment is harsh and frequently exposed to chemical washdowns. The EZ-SCREEN LS with hygienic enclosure keeps personnel safe while preventing water and chemical damage to the light screen.

Videos

LS Safety Light Curtain with IP69K Hygienic Enclosure

LS safety light curtains are available with an IP69K hygienic enclosure that resists high-pressure, high-temperature washdown and aggressive chemical cleaning. They are ideal for use in food, beverage, and pharmaceutical applications where maintaining sanitary conditions is critical.

EZ-SCREEN LS Light Curtain Product Overview [Video]

The LS is an easy-to-use safety light screen system for machine safeguarding, built to withstand challenging environments common to both manufacturing and packaging.

![Intuitive Safety Solutions [Video]](/content/dam/banner-engineering/projects/video-thumbnails/intuitive_safety-new.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

Intuitive Safety Solutions

See how combining easy-to-use safety and indication devices can help keep your operations running smoothly, prevent injury, and make safety more intuitive.

How to Set Up Muting with LS Safety Light Curtain

Learn how to set up the XS safety controller to work with a mute arm kit and LS safety light curtain. Banner’s pre-assembled mute arm kits are available in L, T and X configurations as a plug-and-play solution for end of line packaging applications.

Banner Engineering Cascading Safety Light Curtains

Learn how Banner Engineering's light curtains' cascade signals outpace the competition, and how that translates to savings in the factory.