Vehicle Detection Sensors for Car Washes

Banner’s T30RW Wash Down Series Radar Sensors keep car washes moving smoothly, reliably detecting vehicles entering and exiting despite water, mist, and steam.

Increasing vehicle throughput in a car wash while maintaining consistent, high-quality service requires minimizing equipment downtime and maximizing operational efficiency. Water supply quality, chemical delivery, air pressure and vacuum system health, conveyor operation, and vehicle positioning—Banner can optimize them all.

Banner’s large selection of rugged, reliable sensors and easy-to-implement monitoring solutions is helping car wash operators avoid wasting water and chemicals, perform time-saving predictive maintenance, and improve customer satisfaction.

Discover how Banner’s condition monitoring and vehicle detection solutions can optimize your car wash facility. Download the Car Wash Solutions brochure to learn about:

A car wash needs to know when a vehicle approaches not only to make sure entry doors open and close at the proper times, but also to let the wash system know when to begin its cycle. Doors that don’t open can quickly lock down an operation or damage vehicles by closing too soon. The wash may not start at all if it doesn’t know a car has reached the correct location.

Featured Product: T30RW Washdown Series Radar Sensors

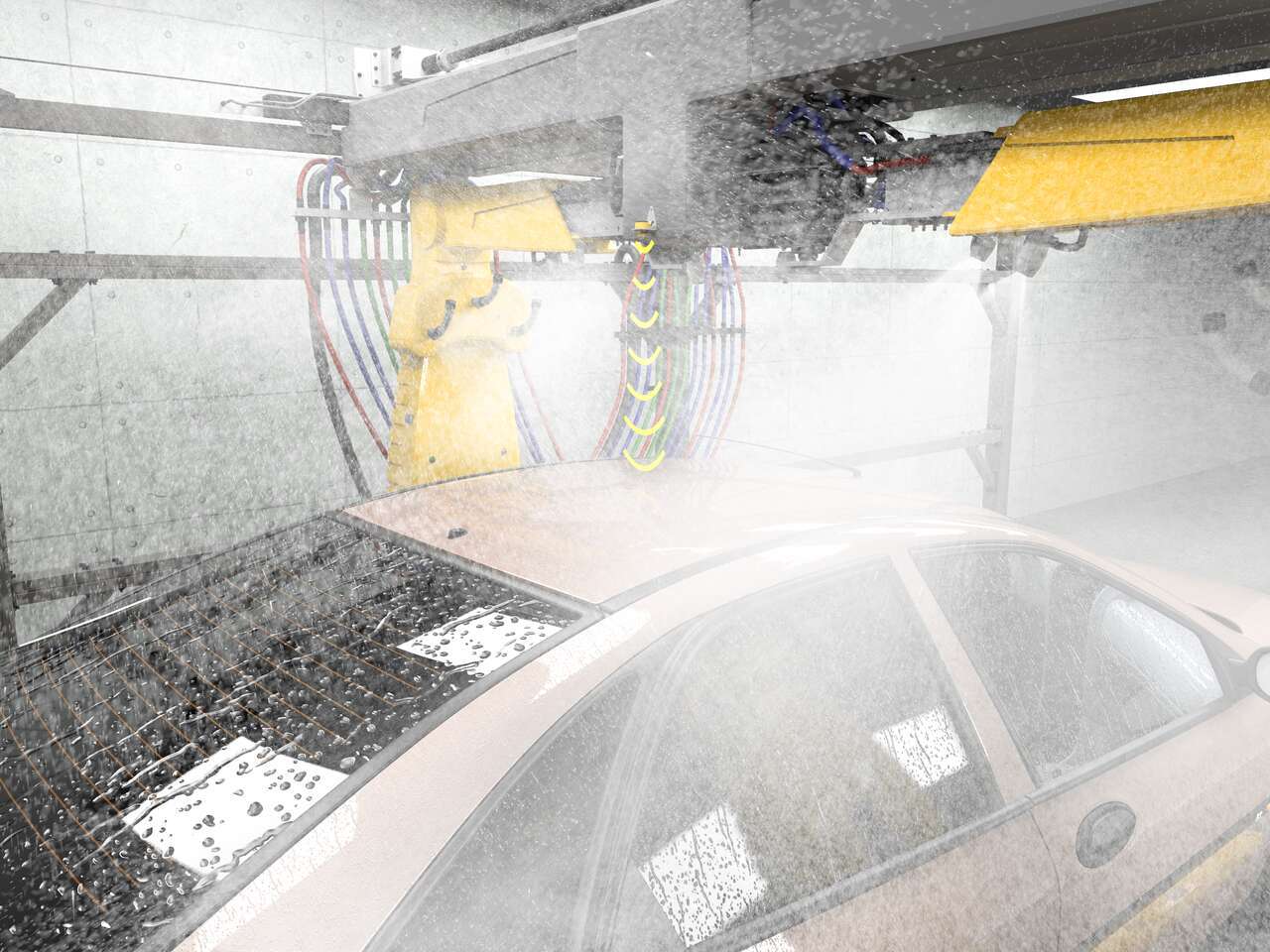

Extreme conditions inside a car wash—high pressure spray, drastic temperature changes, mist, steam, and high humidity—can hamper vehicle detection. On top of environmental challenges, the limitless variations in vehicle color, shape, size, and surface reflectivity, plus movement through the wash cycle, make vehicle detection and positioning challenging.

Featured Product: QS30 High-Performance Photoelectric Sensor

As soon as a vehicle leaves the tunnel, the wash system needs to know it can start the conveyor and bring the next car in. If the car wash has incorrect vehicle location information, the exit door may not open when needed, or the conveyor could push a vehicle into one stopped at the exit. Also, a car can be stuck waiting too long at the entrance if the system doesn’t realize the tunnel is available.

Featured Product: T30RW Washdown Series Radar Sensors

Vacuum motors and filters are two potential failure points that can impact the quality and availability of this service. Early motor wear, loose fittings, poor alignment with the vacuum pump, and other problems can cause unexpected system failure. Also, filters require periodic maintenance, but cleaning them too often is costly, and waiting too long can impact system performance.

Featured Products:

Q45 Wireless Differential Pressure Sensor

Q45 Wireless Vibration and Temperature Sensor

A vacuum system helps deliver a great customer experience, so the impact of unexpected motor failure is felt immediately. To maximize uptime, the electric motor powering the vacuum pump must continue functioning properly.

Featured Product: Q45CT Wireless Current Sensor

Pressure fluctuations in the main water line can cause inconsistent wash quality and operational inefficiencies. A complete loss of pressure can indicate a major problem upstream.

Featured Product: Q45 Wireless Pressure Sensor

The conveyor system inside the car wash tunnel requires all parts to work together as one continuous process. Any downtime due to a failed conveyor motor or gearbox completely halts operation and revenue generation.

Featured Product: Q45VAC Vibration and Temperature Sensor

High-pressure water pumps are susceptible to performance degradation over time, whether from normal mechanical wear, poor water quality, or high temperatures. Pumps that are not functioning properly may not deliver proper water pressure, which can compromise the cleaning process.

Featured Product: Q45VTPD-QM30 Vibration and Temperature Sensor

Sudden air compressor failure can quickly halt an entire car wash operation. Compressed air systems are typically always on, even when the facility is closed. This means that, over time, any air leaks can cause compressors to run unnecessarily and shorten component lifespan.

Featured Product: Q45CT Wireless Current Sensor

Beyond the compressor, problems can arise in the compressed air delivery system. Leaks can make the compressor run more often than needed, leading to excessive energy use. If the leaks become severe, they can impact the performance of downstream equipment.

Featured Product: Q45 Wireless Pressure Sensor

Unexpected issues with water supply pumps or buffer tank levels can hinder efficient water delivery, negatively impacting the quality of the wash process. Significant operational disruptions may occur if the main water supply becomes unavailable.

Featured Products:

Q45 Wireless Vibration and Temperature Sensor

Q45 All-in-One Wireless Ultrasonic Sensor

The reverse osmosis system relies on semipermeable membrane filters to provide pure water for effective cleaning. If scale builds up and clogs these filters, less pure water gets through to the storage tanks which may negatively affect car wash operation and quality.

Featured Product: Q45YAA Wireless Ultrasonic Sensor

The many different sensors in a car wash monitoring system connect to a gateway, such as the DXM1200 Asset Monitoring Gateway with CLOUD ID. This gateway collects data from each sensor and sends it to the cloud via either a hardwired Ethernet or cellular network connection. The built-in display aids setup and diagnostics, such as the onboard site survey tool which shows wireless sensor signal strength between the sensor and gateway. Providing clear signal strength feedback helps make optimal device placement easy.

Featured Product: Asset Monitoring Gateway with CLOUD ID

Banner’s T30RW Wash Down Series Radar Sensors keep car washes moving smoothly, reliably detecting vehicles entering and exiting despite water, mist, and steam.

Banner’s K50R radar sensor is a reliable, cost-efficient, externally-mounted solution for precisely measuring levels of car wash chemicals in storage tanks.

T30R sensors from Banner Engineering excel in vehicle-detection applications, even in harsh environments like car washes. As a radar sensor, the T30R detects the position of cars, trucks, and other large objects despite the presence of excess water, mist, and steam.

WLS27 LED strip lights provide brilliant, even illumination in difficult environments like this. Each light is protected against environmental challenges and corrosion by a shatterproof, water-resistant polycarbonate shell. A redundant sealing method prevents water ingress to achieve IEC IP66, IP67, and IP69K ratings. These cost-effective LED light strips will provide vivid, low-power, maintenance-free illumination throughout their 50,000 hour or more lifespan.

Indicator lights intuitively direct traffic through truck wash stations to ensure efficient flow of vehicles through the wash. However, high-pressure washdowns, cleaning agents, and outdoor environments make status indication challenging. Learn why the WLS27 segmented strip lights are a better alternative to traditional stoplights and can help improve efficiency at truck wash stations.

Detect vehicles as they travel through a car wash. Sensor solution with IP69K-rated housing and infrared light to burn through mist and steam.

CLOUD ID technology simplifies setup by allowing gateways to automatically recognize sensors and configure a cloud dashboard. This technology is found in many of Banner’s wireless sensors that measure vibration, differential pressure, temperature and humidity, tank level, and more.

VIBE-IQ vibration monitoring software uses machine learning to simplify the process of setting warning and alarm thresholds for rotating assets like motors and gearboxes. The software continuously monitors vibration for changes, automatically sending warnings and alerts to ensure optimal performance and prevent unplanned downtime. VIBE-IQ does all the complicated analytical work, making the process effortless for users.

This tool will help you build out your car wash monitoring system. Start by choosing one asset monitoring gateway, then add up to 40 sensor nodes to monitor all critical assets in your facility. If you have any questions, please contact a Banner engineer and we will be happy to help you build your car wash monitoring solution over the phone or via chat.

Choose one of the Asset Monitoring Gateways, either 900 MHz or 2.4 GHz, depending on your wireless connectivity needs. You can only select one gateway to add to your bundle before proceeding to your next step. If using a cellular provider, refer to the carrier listed in the second bullet of each gateway to ensure you choose the correct one.

In the next step you will select the sensor node(s) for your specific monitoring system. The sensor node selection will automatically be filtered to match your Asset Monitoring Gateway frequency.

You’re about to make a change which will affect the compatibility of other items you’ve chosen in later steps. By making this change you understand that you will have to complete all subsequent steps again.