DXM1200 IIoT Gateway Series

Banner’s DXM1200 IIoT Gateway wireless controllers collect and process condition monitoring data from nearly anywhere, then sends anywhere in the world.

A car wash depends on multiple systems working in tandem. Failure in any piece of equipment could cause an unexpected shutdown, resulting in lost revenue and unplanned maintenance.

But Banner Engineering can help you detect equipment breakdowns before they happen.

Maximize vehicle throughput and reduce unexpected downtime with Banner Engineering’s Predictive Maintenance Solutions for Car Washes.

To monitor equipment in the back room, use Banner’s Q45 All-In-One Series sensors, starting with an ultrasonic model that accurately measures the water level in the storage tanks. The vibration and temperature of the delivery pump’s motor gets monitored with another peel-and-stick Q45, and an additional Q45 monitors the water pressure on the main water line.

Further down the line, monitor the vibration and temp of all the different distribution pump’s motors, such as at the detergent pump station, sealer stations, and the high-pressure water pump stations.

Additionally, monitor the reclaim storage tanks for low water levels, which may indicate the RO’s filter needs cleaning. The reclaim delivery pump’s motor is also outfitted with a temp and vibration sensor to alert users to mechanical maintenance needs.

But monitoring solutions don’t have to stop at the water system; nearly any equipment can be monitored, such as the pneumatic air system. Temperature and vibration sensors monitor the air compressor motors alongside a current sensor for consistent power usage, as well as a pressure sensor on the primary air line.

Outside, monitor the central vacuum’s motor with a temp and vibration sensor. The filter’s efficiency can be calculated by comparing the air pressure both upstream and downstream of the separator, indicating when the filter needs cleaning.

All the data from each of these sensors is transmitted wirelessly to a DXM controller mounted in a safe and convenient location. Sensor calculations are performed inside the controller, and data can be transmitted to wherever you need it via Ethernet cable or a cellular connection. Additionally, alerts can be sent to workers via email or text message, so mechanical problems can be addressed quickly.

But, passive monitoring doesn’t have to stop there.

Back in the tunnel, use a temperature and vibration sensor to track the machine health and performance of the conveyor’s motor and gear box. Additionally, consider using a Q45 to track vibration on the air blowers.

Next, add a T30RW radar sensor to the tunnel entrance and exit to reliably detect when vehicles arrive and leave.

Further inside the tunnel, accurately detect vehicles at specific locations, such as an applicator arch, with the QS30 Photoelectric Sensor.

And speaking of applicator arches, Banner's extensive line of customizable RGB lights, many of which are programmable and animated, will add an exciting splash of color and movement while also indicating different wash levels, customer-selected sealers, progress indication, and more.

The only limit to indicator integration is your imagination.

To learn more, visit BannerEngineering.com/carwash

Banner’s DXM1200 IIoT Gateway wireless controllers collect and process condition monitoring data from nearly anywhere, then sends anywhere in the world.

Indicador programável polivalente em uma janela plana ou cúpula de 50 mm que proporciona indicação mais brilhante e destacada com opção de compatibilidade com o software Pro Editor ou comunicação IO-Link para maior versatilidade e customização.

As Luzes Indicadoras K70 são grandes luzes indicadoras de 70 mm que suportam até cinco cores em uma única luz. São indicadores claros, resistentes e coloridos que podem ser usados para uma grande variedade de aplicações.

QM30VT Series vibration and temperature sensors offer exceptional levels of accuracy to detect even slight changes in machine health and performance, enabling early identification of potential problems.

Modelos com grande poder de detecção com alcances de até 200 m e saída de relé e/m disponíveis.

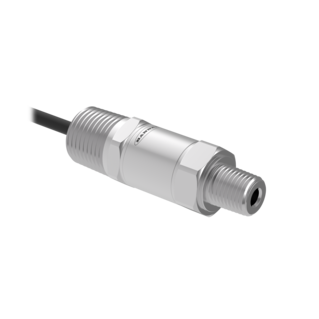

The Performance Series all-in-one pressure sensor and wireless node makes it easy to monitor pressure levels on systems and equipment in remote and hard-to-access locations without wired infrastructure to connect devices.

Os dispositivos all-in-one da Série Q45 combinam um node e sensor sem fio e alimentação por bateria em um dispositivo de fácil implementação que monitora ativos e equipamentos em locais remotos e de difícil acesso.

O sensor T30R é uma alternativa com maior alcance aos sensores ultrassônicos e fornece detecção e feedback de posição mais confiáveis em condições externas extremas e em outros ambientes desafiadores. Apresenta uma zona morta menor, maior precisão e a capacidade de detectar uma maior variedade de alvos do que os tradicionais sensores de radar de 24 GHz.

Os Sensores de Temperatura e Umidade Sure Cross® funcionam em diversos ambientes oferecendo medições de temperatura e umidade. Utilizados com os Rádios Sure Cross, esses sensores facilitam o monitoramento de condições ambientais sem necessitar de uma fiação dispendiosa para os pontos de monitoramento.

Torres de luz grandes e brilhantes fornecidas pré-montadas ou em segmentos modulares para indicações personalizadas. As luzes ficam cinzas quando desligadas para evitar falsas indicações.

Banner is expanding its offering of the WLS27 Series Strip Light to include programmable models with RGBW LEDs for use in indication, illumination and inspection applications. These new models will be programmable with Banner’s Pro Editor software or IO-Link communication.

Iluminação LED com perfil de 21 mm para vários tipos de aplicações industriais. Disponível com sensores de movimento, várias lentes e janelas para máxima flexibilidade.

Application solutions, new product updates, answers to frequently asked questions, and more delivered 1-2 times a month.