Zero Defect Standard on Industrial Winder [Success Story]

Customer Requirement: Detect any defects on fiberglass and glass thread products as they are being spooled

Solution: SureCross® DX80 FlexPower® Gateway, SureCross® DX80 FlexPower® Node

Why Banner? Complete Wireless Operation - Battery powered Node and sensor communicate wirelessly to remotely located Gateway

Customer Benefits

Ease of Installation – Wireless system adapted to existing infrastructure

Low Maintenance – Expected battery life for node and sensor of two or more years

Quality Assurance – Early error detection and correction reduces material waste

Background

A successful manufacturer of specialty industrial yarns makes fiberglass and glass thread products for applications in the automotive, aerospace, military and composite materials industries. To help maintain their high standards and minimize costly product returns, they established a goal of zero product defects. To meet this goal, the company needed an automated thread inspection system.

Challenge

Industrial spooling machines rotate constantly at a high rate of speed, making standard wired monitoring solutions difficult to implement. The lack of an auxiliary power supply necessitates an independently powered solution. A customized wired solution would require equipment designed specifically to work on rotating machinery, raising costs and complicating system design and operation.

Solution

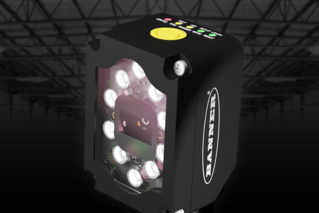

The SureCross® DX80 FlexPower® wireless network was the ideal solution. The Node is protected by a rugged IP67 rated enclosure and deployed inside the winder. The open design of the Node made it easy to integrate a third-party inductive proximity sensor into the solution. One internal 3.6V lithium battery supplies power to the Node and the sensor and has an expected battery life of two or more years in this application.

System design was simple and effective. As the thread is spooled it passes through a die. In the event of a defect or a “blob,” the die will move. The movement is detected by the proximity sensor, communicated to the Node and transmitted to a remotely located Gateway. Because of the quick response time (63ms), the system can be stopped almost as soon as the error has been detected, allowing the operator to remove the “blob” and save the spool.