Illumination for Visual Inspection on a Printing Press

High visibility is critical during inspection of product in flexographic printing. Proper illumination also assists in monitoring machine performance. Flexography involves a variety of inks and solvents, which makes the printing machine a Class I Division 2 hazardous area. The chemicals used in inks and solvents can be potentially dangerous and proper care needs to be taken when using factory automation products in these settings. Learn how the HLS27 LED Strip Light can be used to solve this application.

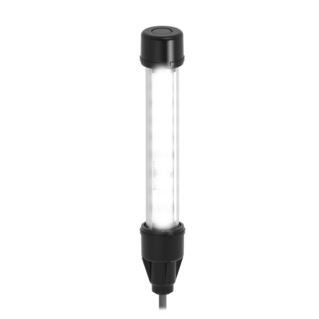

Lighting near a flexography printing machine is difficult because the ink and solvents create a Class I Division 2 hazardous workspace. The explosive chemicals used in printing have a low likelihood of being present in the immediate vicinity, so the bright HLS27 LED Strip Light is a great solution. Proper lighting on these machines is in high demand to ensure high quality inspection and efficient manufacturing processes. Without suitable illumination, operators can’t verify print quality or monitor machine performance.

The HLS27 uses bright LED lights in a sturdy aluminum housing and shatterproof shell that has water-resistant IEC IP66 and IP67 rating, for use in the harsh indoor printing environment. The strip light has a low-profile, space-saving design that conveniently fits into the machine without obstructing the equipment or the view. The slim light installs easily with stainless steel brackets and does not require any additional enclosures. Automatic temperature protection is also built into the unit to manage heat and protect product lifetime. If the light reaches anything above 50°C it will dim to lower the temperature to safe levels.

Eight different length options from 145 mm to 1130 mm give manufacturers more versatility when selecting lighting for use on the machine. Dimming and color options mean that lights can be selected to meet specific demands. Single- and dual-color models of the HLS27 are available as well as models with Hi/Lo/Off wiring or PWM dimming.

- Rugged, water-resistant strip light use bright LEDs to safely illuminate the inspection area.

- The HLS27 does not require an additional enclosure and has a slim, robust design that fits easily into new and existing applications

- Dual color models can be used for direct status indication, to supplement illumination with indication, or to provide colored illumination. For example, a green light can create contrast to facilitate visual inspections.

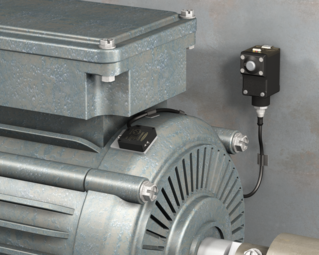

![Vibration Monitoring a Main Air Handler [Success Story]](/content/dam/banner-engineering/3d-renders/application-notes/predictive-maint/qm30vt-motor-vibration-detection.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Predictive Maintenance of Motors and Gearboxes on Large Cranes [Success Story]](/content/dam/banner-engineering/photography/general---stock-photography/stock_photo_new/bigstock-In-A-Port-49071524.jpg/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Predictive Maintenance of Rotating Parts on Conveyor [Success Story]](/content/dam/banner-engineering/photography/general---stock-photography/stock_photo_new/AdobeStock_111970609.jpeg/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Medição de Temperatura de Remediação Térmica [História de Sucesso]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2013/SURE-CROSS-Flex-Power-w-RTD---Temp-Measure-in-Flour-Mill.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Detecção Consistente de Garrafas Plásticas Transparentes em um Transportador [História de Sucesso]](/content/dam/banner-engineering/photography/general---stock-photography/stock_photo_new/bigstock-Bottle-Industry-30664220.jpg/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Detecção de Várias Marcas de Registro [Caso de Sucesso]](/content/dam/banner-engineering/photography/general---stock-photography/valueprop/edited/wcc-migration/2015/R58_roll_closeup.jpg/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Simplificar o Gerenciamento de Recursos de Segurança [História de Sucesso]](/content/dam/banner-engineering/photography/general---stock-photography/valueprop/edited/wcc-migration/2015/Algus_MKuhlow.jpg/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Sensor de Visão para Ler Códigos QR [História de Sucesso]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2014/iVu-Plus-BCR-Label-Verification---Transmissions.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Códigos de Barras Ultravioleta para Rastreabilidade [História de Sucesso]](/content/dam/banner-engineering/photography/general---stock-photography/valueprop/edited/wcc-migration/2015/UVBarcode_2_small.jpg/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Operator Guidance Solution [Success Story]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2013/PVD_QS30LE_OTB_K50L_Bin-Pick-for-Transmission-Plate.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![LED Light Bars Outshine Fluorescents, Reduce Machine Build Times & Expenses [Success Story]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/WLB32%20Muti-Station%20Test%20Workstation%20Illumination%20(High_Res_PSD).psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Long-Lasting LEDs Install Quickly to Illuminate Web Inspection Stations [Success Story]](/content/dam/banner-engineering/photography/success-story-photography/WLB32-LED-Lights-Web-Inspection.jpg/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Indicação de Status em Veículos Sem Motorista [História de Sucesso]](/content/dam/banner-engineering/photography/general---stock-photography/stock_photo_new/AdobeStock_189577689.jpeg/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Medição Precisa de Ingredientes de Padaria [História de Sucesso]](/content/dam/banner-engineering/photography/general---stock-photography/valueprop/edited/wcc-migration/2015/dropbox3.jpg/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Inspeção de Conectores Pequenos [História de Sucesso]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2014/LE550-Vehicle-Seat-Weight-Sensor-Connector.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Zero Defect Standard on Industrial Winder [Success Story]](/content/dam/banner-engineering/photography/general---stock-photography/valueprop/edited/wcc-migration/2015/Fotolia_51604759_M.jpg/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![LED Lights Used To Inspect Liquid Pharmaceuticals [Success Story]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2011/WLA-IV-Bag-Manual-Inspection---Particulates.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Presença de Tubos de Ventilação na Enchedora [História de Sucesso]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2013/iVu-C-Mount-Remote-washer-Tube-Inspection.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Medir o Tempo de Saída Durante Emergências [História de Sucesso]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2014/R-GAGE-Vehicle-Detection---Firehouse.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Otimizar Negócios de Drive-Thru com Detecção de Veículos Sem Fio [História de Sucesso]](/content/dam/banner-engineering/photography/general---stock-photography/stock_photo_new/shutterstock_38753656-orange.jpg/jcr:content/renditions/cq5dam.thumbnail.319.319.png)