Todas as Soluções para Estações de Trabalho

-

Chamada para Coleta de uma Estação de Montagem para um AGV

Chamada para Coleta de uma Estação de Montagem para um AGV

• Remover rapidamente os paletes cheios das estações de montagem • Permitir a comunicação direta das estações de montagem com os AGVs • Melhorar a eficiência do processo usando dados de tempo de resposta

-

Temporizador de Montagem em Estação de Trabalho Ocupada

Temporizador de Montagem em Estação de Trabalho Ocupada

Os botões touch K50 Pro com comunicação IO-Link exibem o takt time no campo de visão dos trabalhadores para que o ritmo de montagem permaneça correto e atinja as metas de produção.

-

Barcode Reading

Barcode Reading

O leitor de código de barras iVu BCR verifica os paletes à medida que eles são carregados, identificando quando eles estão cheios. Isso garante que os operadores saibam para qual caminhão ou local no depósito direcionar o palete cheio. Depois que o leitor de código de barras iVu BCR verifica o palete, ele é levado ao depósito para armazenamento ou para uma doca de carga para embarque. O leitor de código de barras iVu BCR da Banner Engineering decodifica uma variedade de códigos de barras, incluindo DataMatrix, Código 128, Código 39, Codabar e muitos outros.

-

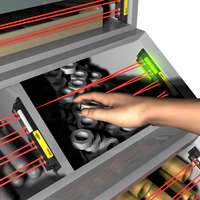

Pick-to-Light Solutions

Pick-to-Light Solutions

Several technologies and solutions are available for bin-picking applications for error-proofing processes. Light arrays prompt the operator for part selection with integral job lights, then reliably sense retrieval of the part, using an array of visible red or infrared sensing beams located in front of the bin.

-

Part Pick Verification for Large Bins

Part Pick Verification for Large Bins

To reduce the risk of error in an assembly operation, a one-piece EZ-LIGHT PVD pick-to-light sensor is placed on the top rail of a shelf, looking down on the shelf opening. The PVD is interfaced with a process controller that is programmed to illuminate the PVD on the bin to pick. After the PVD detects that the assembler's hand has entered and left the bin, the controller signals the PVD on the next bin to pick.

-

Part Pick Indication for Small Bins

Part Pick Indication for Small Bins

To reduce the risk of error in an assembly operation, a one-piece EZ-LIGHT PVD pick-to-light sensor with a 400 mm range is interfaced with a process controller programmed with the correct assembly sequence. The controller makes the PVDs light up in the correct order, to show the assembler which part to pick. After the PVD detects that the assembler's hand has entered and left the bin, the controller signals the PVD of the next bin in the pick sequence to light up.

-

Bin Picking for Order Fulfillment

Bin Picking for Order Fulfillment

In a book packing warehouse, the rack above each carton of books is equipped with a one-piece EZ-LIGHT PVD pick-to-light sensor. A worker fills orders by selecting the quantity of each book specified on the packing slip. To make it easier for the worker to find the cartons from which to pick books, the PVDs above those cartons are illuminated. The PVD detects the workers hand in the carton to verify that the title was picked.

-

Iluminação LED de Alta Qualidade para Estações de Trabalho

Iluminação LED de Alta Qualidade para Estações de Trabalho

Banner’s WLB32 Industrial Light Bar is ideal for workstations. With a Hi/Lo/Off switch, operators are able to control the lighting level and are able to switch the LED light bar off when they are done. The WLB32 provides workers high brightness with even light output and enables numerous tasks in a workstation, including working on a computer.

![Vibration Monitoring a Main Air Handler [Success Story]](/content/dam/banner-engineering/3d-renders/application-notes/predictive-maint/qm30vt-motor-vibration-detection.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Predictive Maintenance of Motors and Gearboxes on Large Cranes [Success Story]](/content/dam/banner-engineering/photography/general---stock-photography/stock_photo_new/bigstock-In-A-Port-49071524.jpg/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Predictive Maintenance of Rotating Parts on Conveyor [Success Story]](/content/dam/banner-engineering/photography/general---stock-photography/stock_photo_new/AdobeStock_111970609.jpeg/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Medição de Temperatura de Remediação Térmica [História de Sucesso]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2013/SURE-CROSS-Flex-Power-w-RTD---Temp-Measure-in-Flour-Mill.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Detecção Consistente de Garrafas Plásticas Transparentes em um Transportador [História de Sucesso]](/content/dam/banner-engineering/photography/general---stock-photography/stock_photo_new/bigstock-Bottle-Industry-30664220.jpg/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Detecção de Várias Marcas de Registro [Caso de Sucesso]](/content/dam/banner-engineering/photography/general---stock-photography/valueprop/edited/wcc-migration/2015/R58_roll_closeup.jpg/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Simplificar o Gerenciamento de Recursos de Segurança [História de Sucesso]](/content/dam/banner-engineering/photography/general---stock-photography/valueprop/edited/wcc-migration/2015/Algus_MKuhlow.jpg/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Sensor de Visão para Ler Códigos QR [História de Sucesso]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2014/iVu-Plus-BCR-Label-Verification---Transmissions.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Códigos de Barras Ultravioleta para Rastreabilidade [História de Sucesso]](/content/dam/banner-engineering/photography/general---stock-photography/valueprop/edited/wcc-migration/2015/UVBarcode_2_small.jpg/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Operator Guidance Solution [Success Story]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2013/PVD_QS30LE_OTB_K50L_Bin-Pick-for-Transmission-Plate.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![LED Light Bars Outshine Fluorescents, Reduce Machine Build Times & Expenses [Success Story]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/WLB32%20Muti-Station%20Test%20Workstation%20Illumination%20(High_Res_PSD).psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Long-Lasting LEDs Install Quickly to Illuminate Web Inspection Stations [Success Story]](/content/dam/banner-engineering/photography/success-story-photography/WLB32-LED-Lights-Web-Inspection.jpg/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Indicação de Status em Veículos Sem Motorista [História de Sucesso]](/content/dam/banner-engineering/photography/general---stock-photography/stock_photo_new/AdobeStock_189577689.jpeg/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Medição Precisa de Ingredientes de Padaria [História de Sucesso]](/content/dam/banner-engineering/photography/general---stock-photography/valueprop/edited/wcc-migration/2015/dropbox3.jpg/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Inspeção de Conectores Pequenos [História de Sucesso]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2014/LE550-Vehicle-Seat-Weight-Sensor-Connector.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Zero Defect Standard on Industrial Winder [Success Story]](/content/dam/banner-engineering/photography/general---stock-photography/valueprop/edited/wcc-migration/2015/Fotolia_51604759_M.jpg/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![LED Lights Used To Inspect Liquid Pharmaceuticals [Success Story]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2011/WLA-IV-Bag-Manual-Inspection---Particulates.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Presença de Tubos de Ventilação na Enchedora [História de Sucesso]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2013/iVu-C-Mount-Remote-washer-Tube-Inspection.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Medir o Tempo de Saída Durante Emergências [História de Sucesso]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2014/R-GAGE-Vehicle-Detection---Firehouse.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Otimizar Negócios de Drive-Thru com Detecção de Veículos Sem Fio [História de Sucesso]](/content/dam/banner-engineering/photography/general---stock-photography/stock_photo_new/shutterstock_38753656-orange.jpg/jcr:content/renditions/cq5dam.thumbnail.319.319.png)