Pick-to-Light for Manufacturing and Assembly

Light Guided Assembly for Lean Manufacturing

Pick-to-light systems support lean manufacturing initiatives. By reducing the risk of human error in production and assembly processes, pick-to-light is an ideal solution for poka-yoke (error-proofing).

Pick-to-light devices visually guide operators to pick the correct parts, in the right quantities and the proper sequence. This reduces errors and defects and increases productivity by eliminating a common source of wasted time like checking and re-checking instructions.

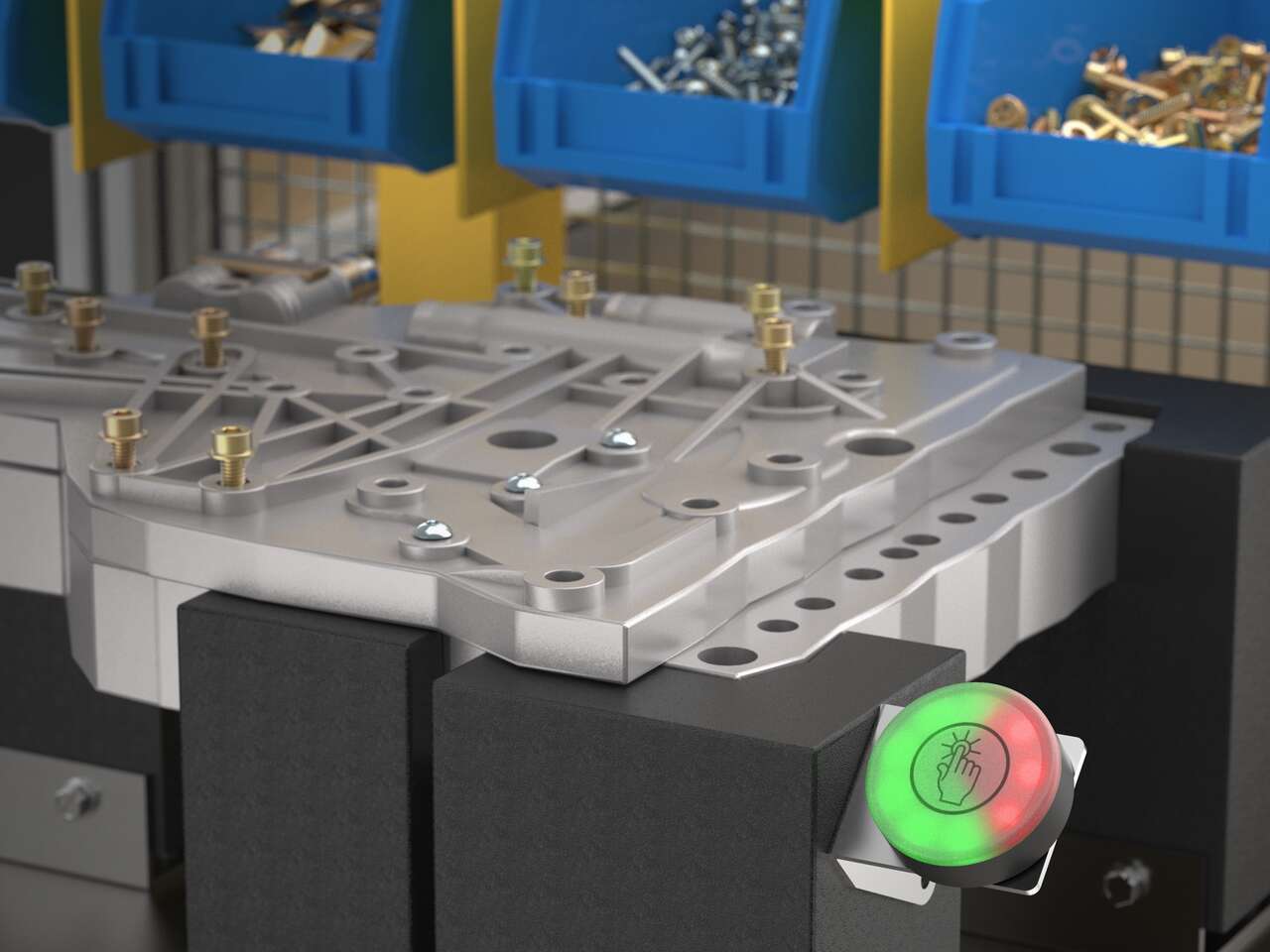

Manual assembly often requires multiple parts and steps to complete, and at each step, there is a risk of human error. An incorrect part may be picked out of a part bin, or parts may be put together in the wrong order. However, accuracy is critical to ensure a high-quality final product. Also, manufacturers need assemblies completed quickly to maximize throughput. The challenge is to increase assembly speeds while maintaining quality.

To improve efficiency and accuracy in assembly applications, it is essential for the assembler to be able to quickly and easily identify the next pick location. A pick-to-light solution identifies the correct bin for the assembler to pick from, detects that the pick has been made, and then notifies the assembler of the location of the next pick.

Flexibility gives users the choice to align with their preferred operating procedure. Technology is adaptable to your processes.

A Feature-Rich Solution for a Complex Process

Errors are common when parts are manually assembled, and there is a demand for a variety of different parts. Similar components and hard-to-follow instructions may lead to a human error during production which then slows down the entire process and introduces defects.

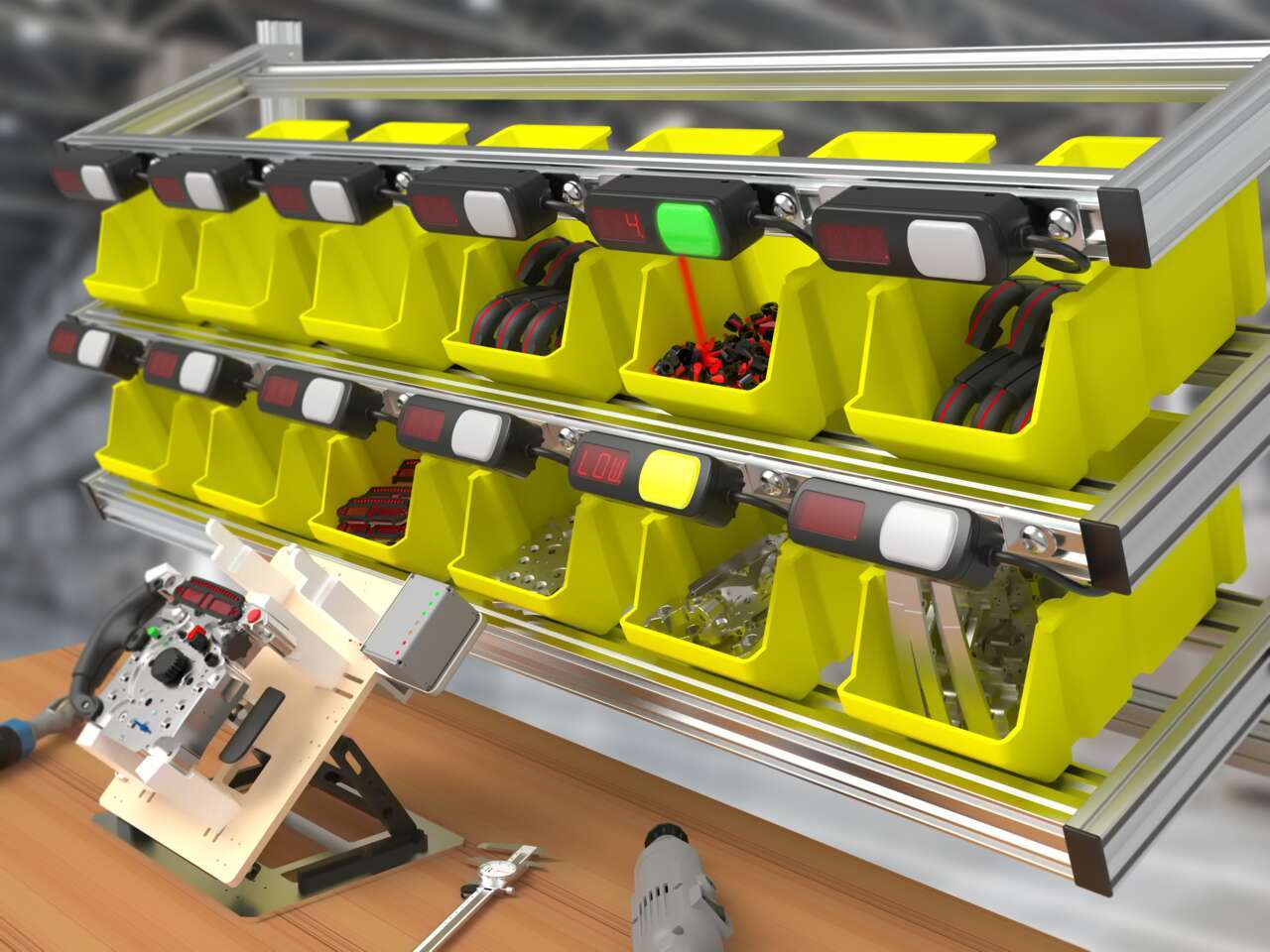

Using pick-to-light sensors at multiproduct assembly stations lessens the number of inaccuracies, speeds up build time, and makes training simple and easy.

In this application, a pick-to-light device with an LED indicator, optical sensor, and alphanumeric display provide the guidance necessary to complete complex assemblies quickly and accurately. When a part is needed, the LED indicator lights up, and the display shows the required quantity. The optical sensor then recognizes when the operator has picked the pieces. Once each step is complete, the next pick in the sequence can light up.

A WIreless Pick to Light System

Due to consumer demand for a wider variety of products, manufacturing processes have become more complex. Providing manufacturers with the ability to reconfigure and move assembly stations easily can have real benefits for production efficiency and space utilization.

In this application, wireless K70 pick-to-light devices are deployed across bins on a portable parts rack. A DXM100 wireless controller executes the selection sequence by illuminating the green LED indicator on the K70 corresponding to the part that should be selected. The operator selects the part and touches the K70 to confirm the action. The K70 turns red if activated out of sequence and yellow to confirm the correct process.

The wireless connection allows the assembly station to be moved or reconfigured without rewiring.

Visual Feedback Helps Assemblers Maintain Pace

In addition to guiding picks, LED indicators can also be used to indicate takt time in assembly processes. This visual feedback can help keep an assembler on track and aware of how much time has elapsed without having to look away from work.

Takt time is important to manufacturers because it represents the rate of production that is needed to match demand. Keeping production rates by the estimated takt time is a simple way to maximize profits.

Using the IO-Link compatible K50 Pro touch button is an easy way to ensure that operators are maintaining takt time. Sequence mode is included with IO-Link models and can be used as a timer. The bright LED indicators are easy-to-see and installed directly in an assembler's sightlines for increased efficiency and less distraction from the task at hand.

Scalable, Versatile Pick-To-Light Devices

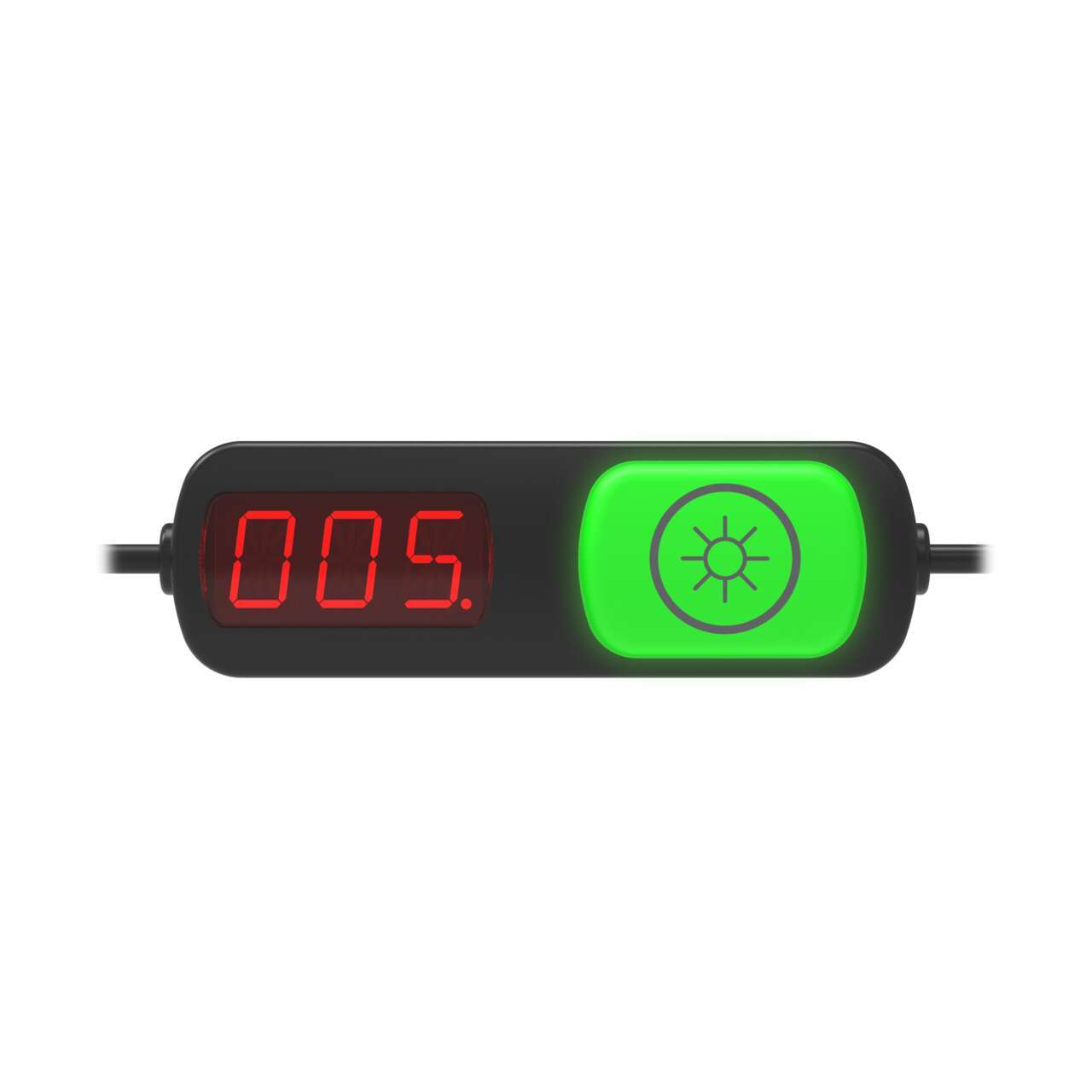

PTL110 pick-to-light devices are multifunctional indicators with options for touch button, optical sensor, and three-digit display, connected in series to create a powerful picking system. With fast response times and flexible installation options, PTL110 systems improve speed, productivity, and quality in picking, kitting and related applications.

- Models available with optical and touch sensor capabilities.

- Optional 3-digit alphanumeric display can be used to indicate part count or provide other instructions.

- M12 connectors for quick and secure installation of multiple devices with no additional cables required.

- Indicator provides fourteen colors and multiple animation functions to differentiate multiple conditions.

- Powered by PICK-IQ®, a purpose-built, Modbus compatible serial bus protocol that uses a Common ID to reduce the typical latency that results from polling multiple devices.

- Can be paired with the DXM700 wireless controller for deployment on carts and mobile picking stations.

Wireless Touch Buttons

Wireless K70 Indicators are bright, 70 mm multicolored indicators offering increased communication possibilities and greater versatility in deployment.

- 70 mm diameter with 30 mm mounting base

- Models are available with up to five colors in one device

- Rugged, water-resistant IP65 housing

- 12 to 30 V dc operation

- Flashing input control

- Sure Cross wireless node built into the base

- 900 MHz and 2.4 GHz wireless options

- Binds easily to a Gateway

- Input wires can be configured as auxiliary sourcing inputs from external devices or as a 20 Hz, 32-bit event counter