IO-Link Master and Industrial Controller

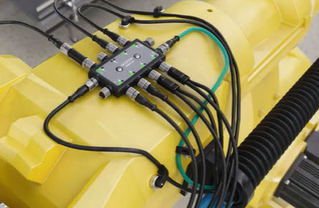

Banner’s DXMR90 Series Controllers consolidate data from multiple connections and provide local data processing as well as accessibility for host systems as a platform for the Industrial Internet of Things (IIoT). The DXMR90 controllers contain individual Modbus or IO-link ports allowing for concurrent communication to many devices. Data is collected in the controllers to facilitate edge processing, convert protocols to Industrial Ethernet, and send information where you need it.

- Converts Modbus RTU and IO-link signals to common industrial Ethernet protocols.; this data can then be sent to a PLC, HMI, SCADA, or to the cloud

- Internal logic controller driven by action rules for easy programming

- Compact housing saves space and weight compared to traditional “block”-style form factors

- Email alerts can be set up directly from the DXMR90

- Equipped with IP65, IP67, and IP68 rated housing for use in challenging environments

- Powered by 12 to 30 V DC

- RS-485, IO-Link (model dependent), and Ethernet communications ports

- User-programmable LEDs for local status indication

- Connects to databases (including Banner's Cloud Data Services) over Ethernet or through a cellular-enabled DXM Controller

- Ideal for IIoT data analytics, condition monitoring, predictive maintenance, OEE analysis, diagnostics, and troubleshooting.

Downloads

Technical Literature

Product Data Files

PLC Support Files

Software

Marketing Literature

Solutions Guide

Application Notes

Monitor Roll Diameter and Increase Machine Uptime

Your machines need a constant supply of materials to keep production going. Knowing when they’re running low is critical. Snap Signal provides this data and makes it available for viewing anywhere it’s needed.

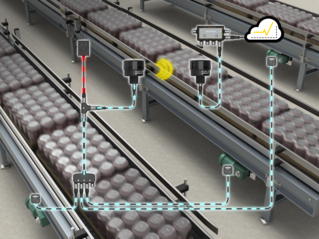

Discrete Sensors to the Cloud

Snap Signal products utilized existing legacy sensors that were already installed to offer valuable insights on process states and error conditions. Product managers were able to monitor machine performance and help optimize throughput via sensor data sent to Banner Cloud Data Services (CDS).

Pressure Sensor Data for Immediate Insights

Snap Signal products connect sensors of various types and convert their signals to a unified serial protocol, making it possible to monitor production facility conditions in real-time, including system pressure.

Temperature Data to the Cloud

Knowing when your system temperature is too high or too low allows you to optimize your application for optimal performance.

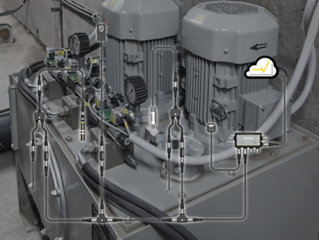

Monitor Hydraulic Power Units

Easily monitor the pressure, current, oil temperature, and motor vibration/temperature of hydraulic power units and other hydraulic machinery. Snap Signal products connect sensors of various types and convert their signals to Modbus data for real-time condition monitoring.

Condition Monitoring of Dust Collection System

Snap Signal converters provide monitoring data so users can spot small performance changes. This solution indicates problems that can be fixed early and fully with preventive maintenance.

Small Motor Condition Monitoring & Predictive Maintenance

Condition monitoring with Snap Signal

Videos

Snap Signal Overlay

Snap Signal is an easy-to-deploy toolkit of IIoT hardware and software that delivers actionable machine data.

Introducing Snap Signal

Increase productivity and unlock your factory’s true potential with ‘Snap-Signal’-- a hardware and software tool-kit for your IIoT evolution, available only from Banner Engineering.

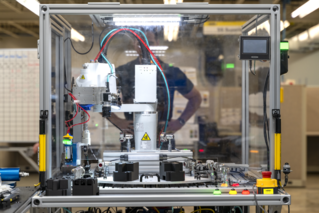

Robotic Assembly Station

Banner Engineering Remote I/O products were used to build an automated system for dispensing a bead of adhesive without the need for an electrical panel.

How-To Guide: DXM Controller with Ignition SCADA

Learn how to connect the Banner DXM Gateway series with the Ignition SCADA software.

-

DXMR90-X1E

DXMR90 Industrial Controller

Power: 12-30 V dc

2 x Female M12 (D-Code Ethernet)

IP67, IP68

Ethernet IP, Modbus TCP, Modbus RTU Client and Profinet

MQTT -

DXMR90-X1

DXMR90 Industrial Controller

Power: 12-30 V dc

Female M12 (D-Code Ethernet)

IP67, IP68

Ethernet IP, Modbus TCP, Modbus RTU Client and Profinet -

DXMR90-4K

DXMR90 IO-Link Master/Controller

Power: 18-30 V dc

Female M12 (D-Code Ethernet)

IP67, IP68

Ethernet IP, Modbus TCP, and Profinet