-

Applications

-

Radar

-

Anti-Collision and Equipment Positioning

Anti-Collision & Equipment Positioning

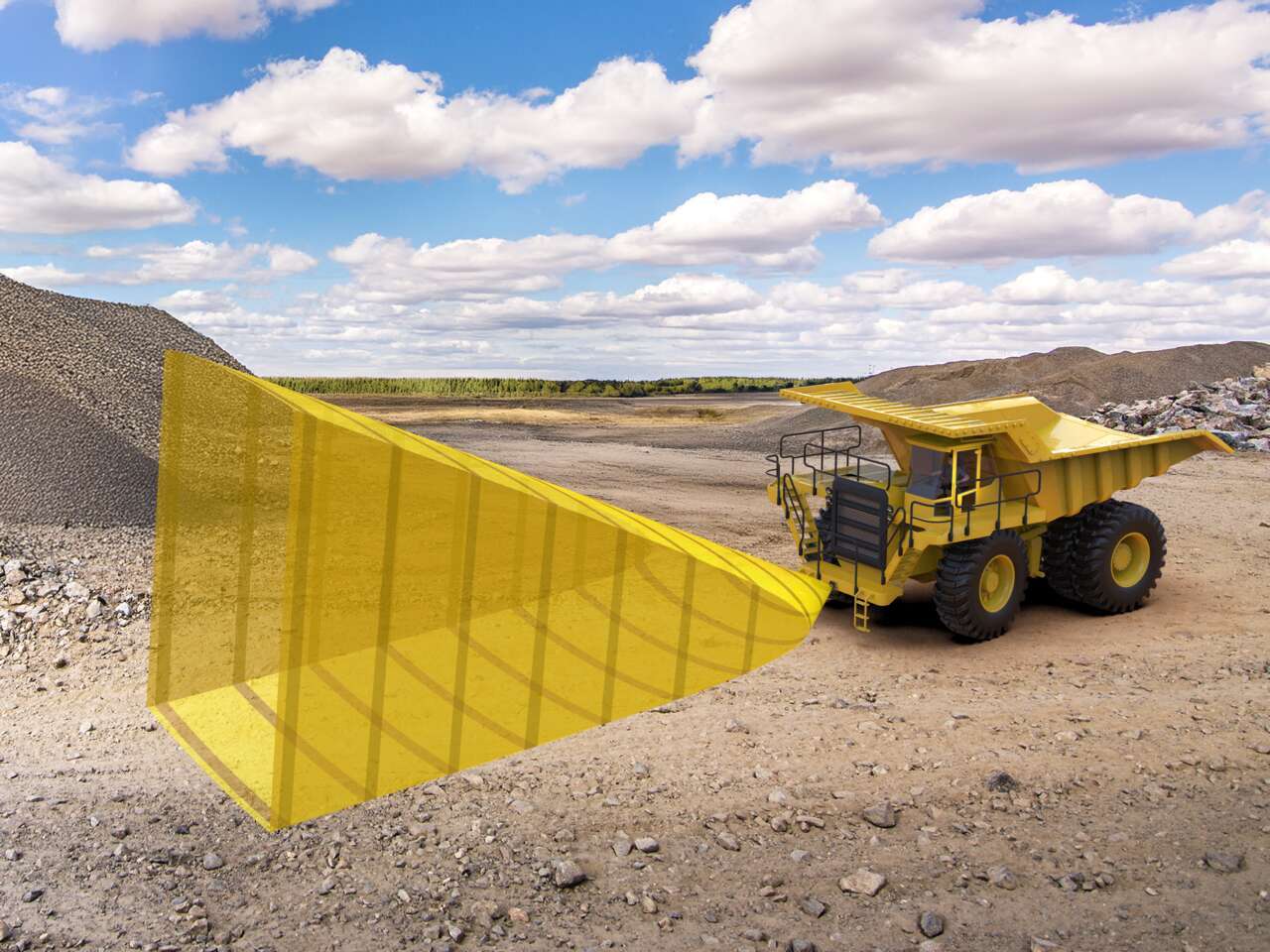

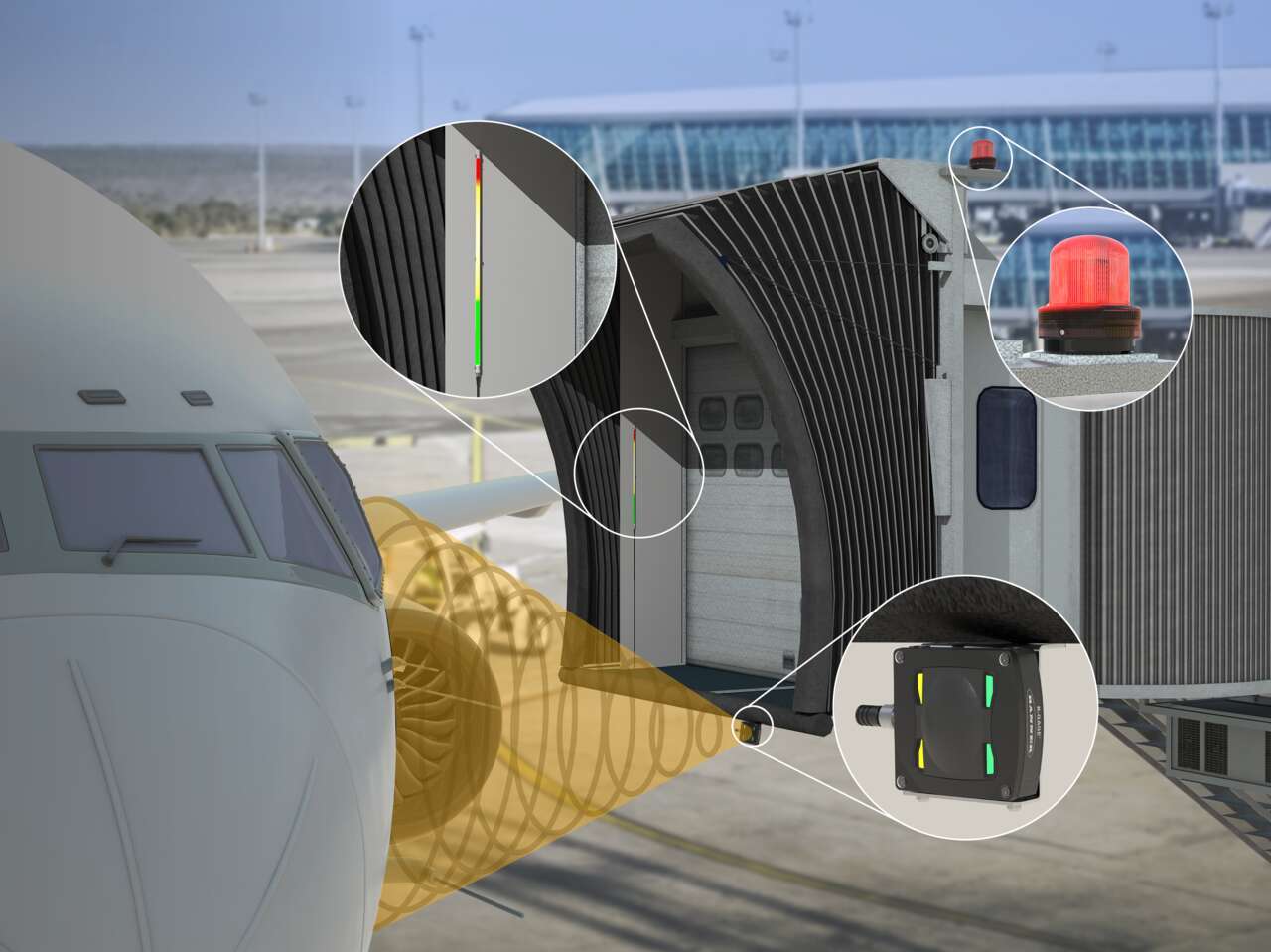

Radar supports two critical needs in operations where vehicles play a central role: avoiding collisions and ensuring accurate equipment positioning. With long sensing ranges and strong resistance to environmental conditions that compromise the reliability of other sensor technologies, radar provides reliable detection of moving and stationary objects, along with a powerful layer of protection to keep operations running.

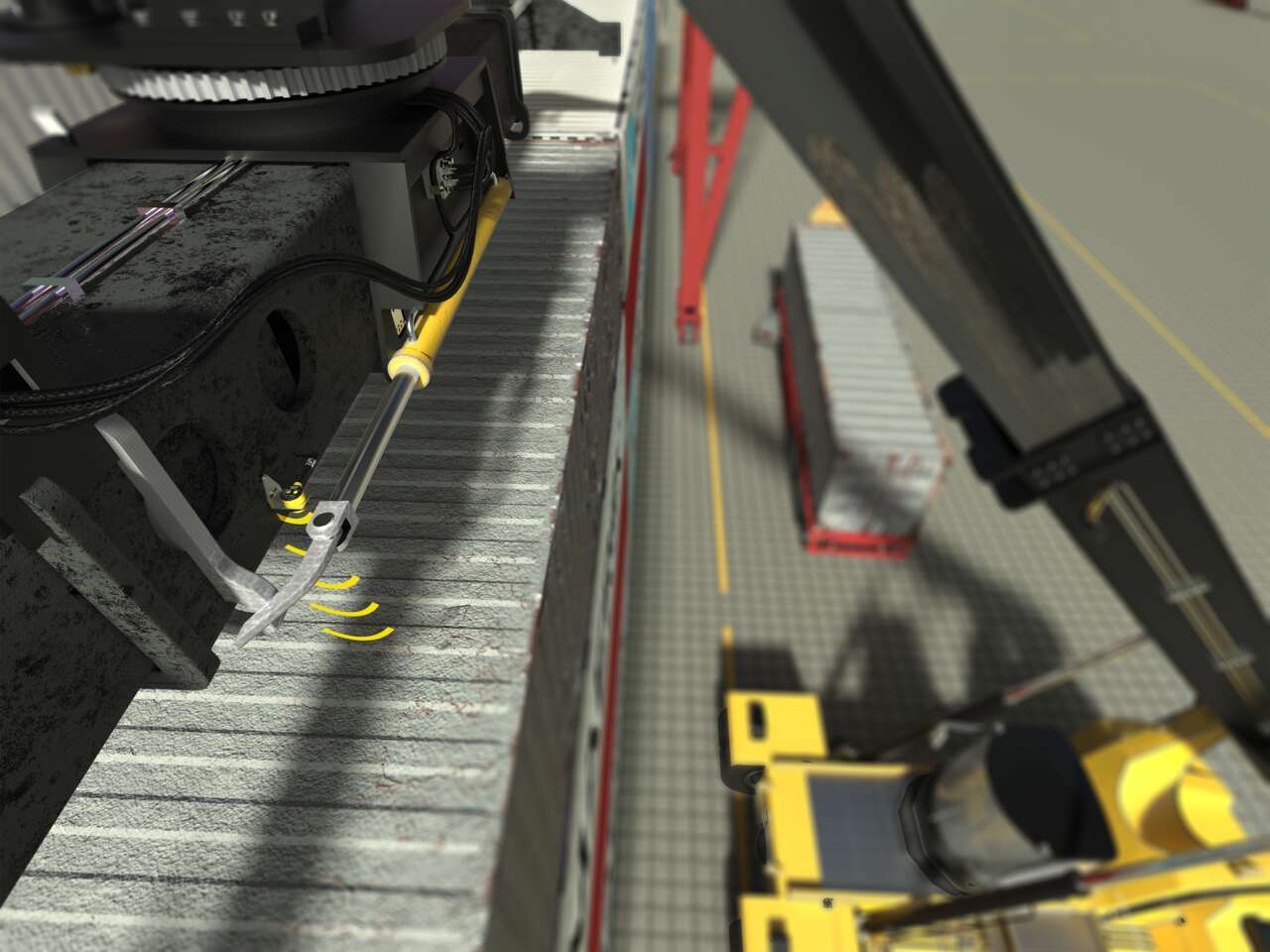

When mounted onboard automated guided forklifts, the Q90R2 radar sensor allows the vehicles to detect and prevent collisions with elevated obstructions, such as improperly placed pallets extended beyond shelves.

Anti-Collision

In dynamic environments where vehicles and equipment are in motion, a momentary lapse in attention can lead to costly collisions. Equipment protection and operator feedback are two complementary anti-collision strategies: one restricts motion, the other informs action, and both help prevent equipment damage. Equipment protection means automating functional restrictions based on object detection—like forcing a stop or governing speed. Operator feedback means using detection to drive indication—like an LED and audible alarm signaling when a forklift gets too close to a structure so its operator can avoid collision.

Equipment Positioning

In applications where consistent distance or accurate alignment are essential, small miscalculations can lead to costly errors or equipment damage. Distance measurement and alignment detection are two common forms of equipment positioning: one helps ensure consistent spacing, the other ensures alignment, and both help ensure a task is completed with greater accuracy. Distance measurement involves maintaining distance relative to another object, like maintaining fixed spacing between vehicles. Alignment detection ensures correct orientation relative to a fixed target, like aligning a lifting device with a docking point.

When mounted onboard a spray boom, the Q90R is able to accurately measure the distance between the boom arm and the ground, triggering the arm to adjust for optimum height clearance across uneven terrain.

Benefits of Radar Sensing

1966

Resistant to wind, rain, snow, fog, and sunlight

5,500+

Long sensing range

30+

No moving parts, durable, less downtime

1966

Operates across a wide temperature range for indoor and outdoor use

5,500+

Highly resistant to interference or crosstalk

30+

Detects moving and stationary objects

DOWNLOAD THE BROCHURE

Radar Sensors for Anti-Collision & Equipment Positioning

See how radar keeps people, equipment, and throughput on track—download the brochure now.

Featured Radar Products

Q90R and Q90R2

The Q90R and Q90R2 radar sensor pairs wide-area detection with precision ranging to keep equipment moving safely and stopping exactly where it should. Customizable sensing zones—configured in minutes with Banner’s Measurement Sensor Software—adapt to shifting layouts and deliver high-resolution position information for docking, staging, or lift alignment. For even greater intelligence, the Q90R2 model features multidimensional sensing that evaluates targets by distance, radial position, and speed thresholds, and it offers two independent detection zones to track and measure multiple objects at once. Engineered for reliable performance in rain, dust, glare, and temperature extremes, the Q90R and Q90R2 radar sensor delivers real-time protection in dynamic indoor and outdoor environments. Bright onboard LEDs give operators instant feedback, while intuitive wiring and Pulse Pro outputs streamline installation. The result: fewer collisions, reduced equipment damage, and spot-on positioning across busy yards, warehouses, and loading docks.

T30R

The T30R radar sensor couples long-reach, narrow-beam detection with high-resolution position information to keep mobile and overhead equipment both safe and precisely aligned. Configurable sensing windows—set in minutes with Banner’s Measurement Sensor Software or IO-Link—track obstacles up to 25 m away and deliver precise ranging for smooth docking, staging, and lift placement. Designed to withstand rain, dust, glare, and temperature extremes, its rugged IP67/IP69K housing ensures consistent performance indoors or out, while bright status LEDs and Pulse Pro I/O outputs simplify wiring and give operators instant feedback. The result: fewer collisions, reduced equipment damage, and spot-on positioning across cranes, gantries, AGVs, and other high-energy applications.

K50R

The K50R Radar Sensor delivers reliable, cost-efficient sensing for short-range anti-collision and equipment-positioning tasks. Two independently configurable outputs create a protective area that both stops forklifts, carts, or AGVs before impact and supplies position information for precise docking, charging, and pick-station alignment—configured easily using Banner’s Measurement Sensor Software or IO-Link. Designed to withstand rain, dust, steam, glare, and temperature extremes, its IP67 housing ensures consistent performance indoors or out. Compact base- or flush-mount options make retrofits easy, and Programmable models integrate multicolor LEDs plus Pulse Pro I/O outputs to give operators instant, controller-free distance feedback. The result: smoother traffic flow, fewer bumps, and spot-on placement in the tightest, highest-throughput zones.